With the increasing importance placed on health by people, the medical industry is also growing, and the requirements for medical equipment and device manufacturing are also higher. Therefore, precision and stable quality machining are required. By utilizing CNC machining , various complex parts and equipment can be efficiently produced. In the medical industry, using CNC machining can produce safer and high-quality medical equipment. These devices can help doctors diagnose and treat diseases more effectively, and can help patients recover faster and better.

So, what is medical CNC machining ? Why is it so important? This article will introduce you to the basic concepts of medical CNC machining and explore its innovative solutions. Please continue to read on.

What is Medical CNC machining ?

Simply put, CNC machining is a process that uses computer programs to control machining machines for precision cutting, drilling, or other process operations. The use of CNC machining technology can improve automation, reduce manual intervention and errors, and thus improve production efficiency. At the same time, CNC machining can also achieve mass production and reduce manufacturing costs. Medical CNC machining applies this method to the medical industry, using advanced CNC technology and high-precision equipment to manufacture medical equipment, equipment, and surgical tools.

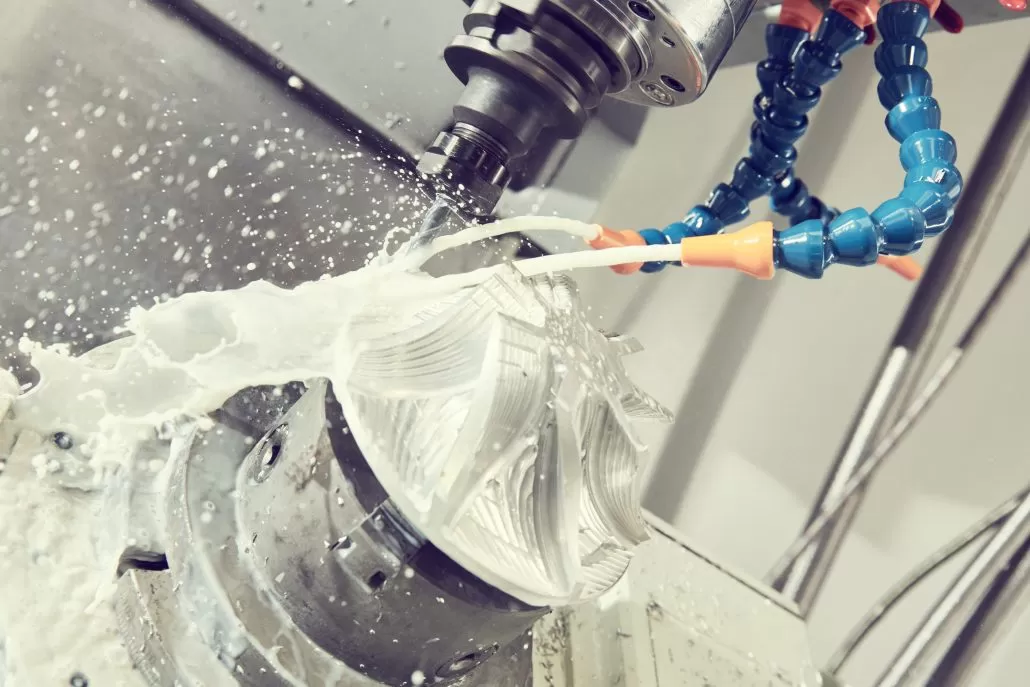

In the field of medical CNC machining, there are many equipment that need to be used, the most common of which are CNC lathes, CNC milling machines, CNC drilling machines, and so on. At the same time, it is also necessary to equip tungsten steel alloy cutting tools, high-speed drill bits, cutting fluids, etc. to meet the machining needs of different products.

Application of CNC machining in medical equipment and apparatus manufacturing

Medical CNC machining technology is playing an increasingly important role in surgical instruments, pacemakers and defibrillators, artificial joints and bone plates, oral implants and dentures, ophthalmic implants and contact lenses.

Surgical instrument

Surgical instruments are a very important aspect in the manufacture of medical equipment and instruments. The manufacture of surgical instruments requires very high precision equipment and technology. The size and shape of instruments, such as surgical tools, orthopedic instruments, cardiac surgery instruments, ophthalmic instruments, etc., can be accurately controlled by medical CNC machining technology. Make it meet the requirements of the use of medical equipment. At the same time, CNC machining can also ensure that the surface of the instrument is smooth, without sharp edges, avoid surgical damage and scratches

Pacemakers and defibrillators

Pacemakers and defibrillators are important devices for treating heart disease. These devices require sophisticated manufacturing processes and materials to ensure their stability and reliability. CNC machining can produce very precise pacemaker and defibrillator components that ensure stability and reliability of equipment performance. In addition, CNC machining can be made to create custom pacemakers and defibrillators to better suit the needs of medical devices.

Eye implants and contact lenses

Ophthalmic implants and contact lenses are very important devices in medical equipment and instruments. These devices require very high precision and quality materials to ensure their safety and reliability. CNC machining technology can be used to manufacture a wide variety of eye implants and contact lenses, such as retinal prostheses, corneal grafts, lenses and more. These devices are vital to the lives of many people with vision problems. CNC machining technology enables the manufacturing of these devices to be more efficient and precise, thus enabling patients to receive the best treatment. At the same time, CNC machining can also be made to tailor eye implants and contact lenses to the needs of different users.

Oral implants and dentures

Dental implants and dentures are a very important aspect of the medical industry. These devices require sophisticated design and manufacturing processes to ensure their durability and reliability. CNC machining can create implants and dentures that are tailored to a specific patient and can be personalized to the patient’s specific requirements. These components ensure the stability and reliability of equipment and instruments. In addition, CNC machining can also create different types and shapes of dental implants and dentures to suit different oral health needs. Thus improving their oral health and appearance.

Artificial joints and bone plates

In the manufacturing process of artificial joints and bone plates, the quality, accuracy and stability of the equipment need to be very high requirements, CNC machining technology can manufacture a variety of prostheses and artificial joints, used to replace and repair the organ loss caused by fracture, degradation and injury, high precision CNC machining can manufacture artificial joints and bone plates more suitable for human body. These devices can have a longer service life and better durability. In addition, they are better adapted to the patient’s unique bone structure, leading to faster recovery and less pain.

Medical CNC machining operation

CNC machining helps to produce parts and products with high precision and strict tolerances. This technique is the process of making high precision, high quality parts through the use of computer numerical control machines. It can be used to make a wide variety of medical devices. Here are some CNC machining operations that are best suited for manufacturing medical parts.

CNC milling

CNC milling technology can be used to manufacture parts in a variety of shapes. This CNC machining technology is especially suitable for manufacturing medical equipment. The machine can cut material from the bottom into the desired shape, making it ideal for making narrow instruments, such as implants and orthopedic instruments. With CNC milling, manufacturers can obtain high-precision parts and ensure that they are up to standard, eliminating the need for manual machining .

CNC turning

Unlike CNC milling, CNC turning is the process of making a part by cutting the desired shape from the top of the material. For the manufacture of circular, semicircular and spiral parts. Examples include tubular devices and other devices that require holes and apertures. With CNC lathes, we can achieve precise internal and external machining, resulting in the manufacture of high precision medical devices, manufacturers can ensure that the size and accuracy of the parts are exactly as required, thus making the device more accurate and safe.

5-axis machining

5 axis CNC machining technology is a relatively advanced technology in medical CNC machining operation, especially suitable for manufacturing complex medical parts. This technique uses multiple axes to move a workpiece and cut it. It allows manufacturers to create very complex designs and beat traditional machining methods. In the medical field, 5-axis machining is commonly used to produce instruments such as high-precision bone marrow drills, tracheal intubations and artificial joints. These devices need to be in good shape to fit the patient’s body.

Turn-milling compound machining

Turning and milling combined machining is a kind of machining technology with high popularity. This method combines CNC milling and CNC turning. Milling and turning operations are carried out simultaneously. The combination machining can improve the manufacturing efficiency and production quality, and reduce the machining times required by traditional machining methods. When used in the manufacture of complex parts and components of medical equipment, the composite machining technology can better ensure the accuracy and consistency of parts. This method is suitable for manufacturing medical instruments and devices requiring high precision and specific shapes.

Advantages of medical CNC machining technology

There are many ways to manufacture medical parts, but CNC machining provides a very efficient, precise machining method. In the manufacturing of medical equipment, CNC machining technology can improve the quality, accuracy and safety of products. The following are the advantages of CNC machining technology for medical parts machining :

High production efficiency

Compared with manual machining, CNC machining can greatly improve production efficiency. This is because automated machining can complete a large number of products in a relatively short time. Moreover, in the production process, because the CNC system has the ability of self-detection and self-correction, so it can timely discover and solve the problems in production, so as to improve the production efficiency and quality.

High precision

CNC machining has the advantages of high precision, you can precisely control the size and shape of the machining. In the medical industry, high-precision components are needed to ensure the accuracy of surgery or diagnosis. CNC machining can produce very precise medical equipment and parts.

Reduce the difficulty of secondary machining

For some complex medical instruments, the traditional machining technology may be more difficult to process again. And CNC machining technology can complete all the work in one machining , so as to reduce the difficulty of secondary machining , effectively improve the machining efficiency.

Wide material selectivity

CNC machining can handle a wide variety of materials, including metals, plastics, ceramics and more. In the medical industry, there are many different materials that can be used to produce a wide variety of medical devices and parts. CNC machining can select the most suitable materials to produce high quality products.

The Impact of CNC machining Technology on the Medical Industry

With the continuous development of technology, the manufacturing and maintenance of medical equipment has become a complex and precise process. The introduction of CNC machining technology has brought more precise machine tool operations, more efficient production processes, more precise component machining , and more precise equipment debugging and maintenance to the medical industry.

CNC machining can easily process various materials and create complex shaped components. In the field of medical equipment manufacturing, CNC machining technology can be used to manufacture surgical navigation systems, orthopedic implants, dental braces, and prosthetics. CNC machining technology can provide high-precision and efficient component development, thereby improving the quality of medical equipment, reducing manufacturing costs, and meeting the needs of patients more quickly.

Longsheng provides medical CNC machining solutions

Longsheng Medical Devices has many years of experience in the online CNC machining field, proficient in various CNC machining technologies, and can provide customized medical CNC machining solutions according to customer needs. Our CNC machining services can process various materials, such as metals, plastics, ceramics, and composite materials. No matter what kind of medical equipment you need, we can meet your requirements and provide you with the highest quality products.

In addition to providing customized machining services, we also provide engineering design and consulting services to ensure that customers’ projects receive the best technical support. Our engineers have extensive experience in medical device manufacturing and are able to provide top-notch design suggestions and solutions.

If you are looking for a reliable medical CNC machining solution, Longsheng is your best choice. We have advanced technology and an excellent professional team, which can provide you with high-quality medical equipment component machining services. Please contact us for customized machining , engineering design, and consulting services

conclusion

With the increasing demand for medical devices, innovative solutions provided by the medical CNC machining industry have become particularly important. Through CNC machining technology, medical device manufacturers can ensure product quality, respond to different material characteristics, and achieve intelligent and customized production. Therefore, the future of the medical CNC machining industry will be more extensive, creating more opportunities and development.

FAQ

Medical CNC machining requires the use of high-precision and high-quality equipment, regular maintenance and upkeep of machines, and strict quality control processes. Through strict quality control, product quality can be guaranteed to meet the requirements of the medical industry.

The commonly used raw materials for medical CNC machining include stainless steel, titanium alloy, polylactic acid ester, etc. These raw materials have characteristics such as high strength, corrosion resistance, and good biocompatibility, making them suitable for the manufacturing of medical devices and human bones and joints.

The process of medical CNC machining includes multiple stages such as design, manufacturing, assembly, and debugging. Among them, design is a very important aspect, which directly affects the quality and production efficiency of products.