CNC machining has become an integral part of the medical industry. From surgical instruments to implantable devices, CNC machining helps produce highly precise parts needed for medical purposes.

One of the advantages of using CNC machining in medical applications is its ability to produce complex parts that would be impossible to manufacture using traditional methods. CNC machining enables the creation of intricate geometries that allow for greater functionality in medical devices. Additionally, CNC machining delivers consistent precision over short and long production runs.

However, the medical industry presents a unique set of challenges for CNC machining. Medical devices must meet strict regulations and quality standards to ensure the safety and well-being of patients. Any inconsistencies or deviations from these standards could result in serious consequences.

CNC Machining Overview

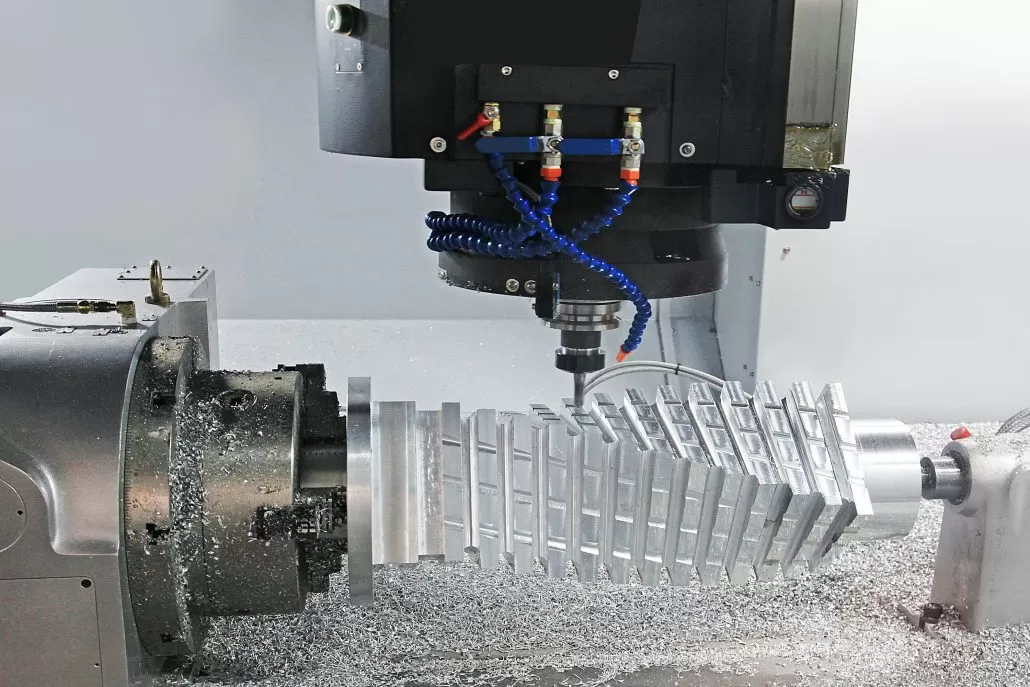

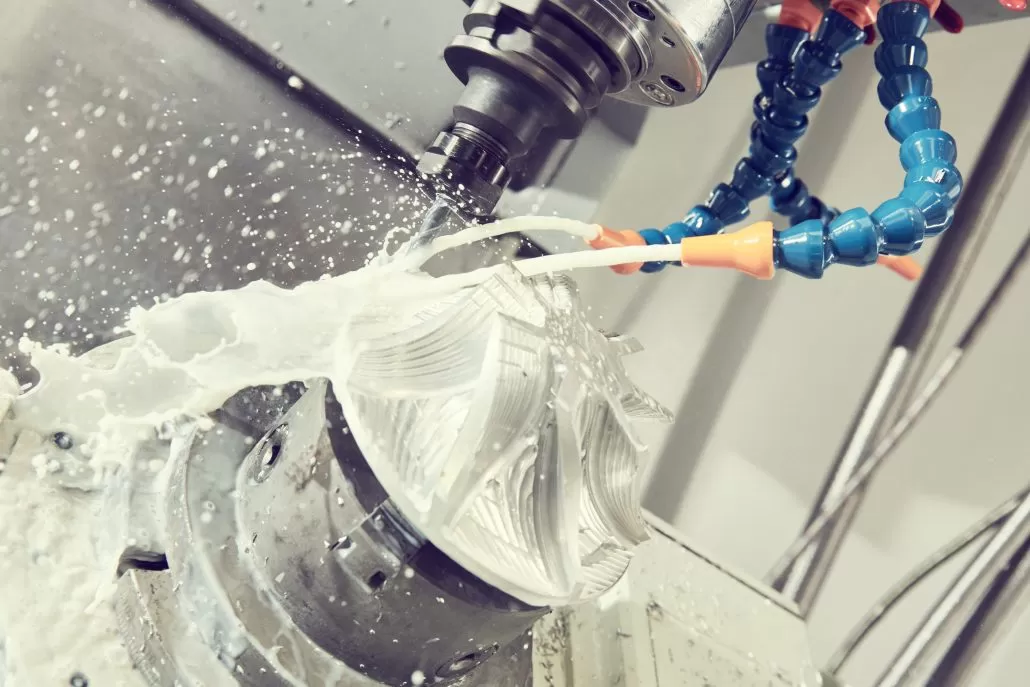

CNC machining is a manufacturing process that uses computer-controlled machines to create complex and intricate parts and components. The process involves using computer software to control the movement of the machine tools, which allows for precise and accurate cuts and shapes.

CNC machining is widely used in several industries, including aerospace, automotive, and electronics. However, its applications in medicine and healthcare have gained significant traction over the past few decades.

The Challenges of CNC Machining for Medical Purposes

One of the biggest challenges facing CNC machining in the medical field is the issue of biocompatibility. Unlike parts produced for other industries, medical components must be biocompatible, meaning they are safe to be used inside the human body without causing harm or causing adverse reactions.

This means that the materials used in CNC machining must undergo rigorous testing to ensure they meet the required biocompatibility standards. Additionally, CNC machined medical parts must undergo extensive testing to ensure that they are free from impurities and do not produce toxic materials when exposed to the human body.

Another challenge facing CNC machining in the medical field is the requirement for traceability. Medical devices and implants must be traceable throughout their entire life cycle to ensure that they meet the necessary safety and quality standards. This means that every component used in the device must be carefully documented, and each device must be tracked from manufacturing to implantation.

Finally, CNC machining for medical purposes requires a high level of expertise and technical knowledge. Medical devices must perform as expected for years, if not decades, after implantation. This means that CNC machining operators must have an in-depth understanding of the unique challenges facing the medical industry and be able to consistently produce parts that meet the high standards required.

how cNC machining for medical purposes differes from other industries

In the medical industry, CNC machining is used to produce complex parts and components used in implantable medical devices such as pacemakers, artificial joints, and dental implants. Additionally, these machines are also used to manufacture surgical instruments, medical tools, and other medical equipment.

However, CNC machining for medical purposes differs from other industries in a few ways.

Quality and Precision

When it comes to the use of CNC machining in the medical industry, one of the primary differences is the level of quality and precision required. Medical devices must meet stringent standards to ensure they are safe to use and provide accurate results. This means that the tolerances for the machining of medical parts are much tighter than in other industries.

CNC machines in the medical industry must also be able to produce parts with repeatable precision. This is necessary to ensure that replacement parts are interchangeable and meet the same high-quality standards as the original. In contrast, other industries may not require the same level of repeatable precision.

Design Requirements

A third difference between CNC machining for medical purposes and other industries is design requirements. Medical devices and implants must meet specific design criteria, such as dimensional accuracy, functionality, durability, and sterilizability, which may vary based on the intended clinical use, the patient demographic, and the healthcare system’s standards. CNC machining for medical purposes must ensure that the designed parts meet the requirements, as well as the safety and ergonomic aspects, such as ease of handling, cleaning, and packaging. In contrast, other industries may have more freedom in design requirements, depending on the product’s functionality and aesthetics.

Materials Used

Another key difference between CNC machining in the medical industry and other industries is the materials used. Medical parts must be safe for use in the human body and must not cause adverse reactions. As a result, the materials used to machine medical parts are often more expensive than those used in other industries.

In addition, the use of specialized materials, such as titanium and cobalt, is common in the medical industry. These materials require special CNC machining techniques and equipment, adding further complexity to medical device manufacturing.

Regulatory Requirements

Finally, the regulatory requirements for CNC machining for medical purposes are much stricter than those for other industries. Medical devices and equipment are subject to extensive testing and validation before they can be approved for use by regulatory bodies such as the FDA.

This means that the machines used in the manufacturing process must meet the highest standards for quality and safety. Additionally, the manufacturers must adhere to strict guidelines for documentation, testing, and validation to ensure that the devices they produce are safe and effective.

Case Studies

To illustrate these differences and highlight the challenges and opportunities in CNC machining for medical purposes, this section presents two case studies of CNC machining for medical devices and implants.

Case Study 1: Customized Cranial Implants

Customized cranial implants are medical devices that replace or augment parts of the skull that have been damaged by trauma, congenital defects, or tumors. CNC machining is ideal for customized cranial implants because of its ability to create complex shapes and contours from biocompatible materials that match the patient’s anatomy. However, the design and production of customized cranial implants require careful collaboration among medical professionals, engineers, and manufacturers, as well as compliance with regulatoryv requirements, such as the FDA’s 510(k) clearance. CNC machining for customized cranial implants must ensure that the implants meet the dimensional accuracy, surface finish, and biocompatibility requirements, as well as the compatibility with the surgical procedure and the postoperative care. In contrast, other industries may not have the same level of customization and collaboration, or the same level of regulatory scrutiny and patient safety concerns.

Case Study 2: Spinal Implants

Spinal implants are medical devices that stabilize or decompress the spine that has been affected by degenerative disc disease, vertebral fractures, or spinal stenosis. CNC machining is also ideal for spinal implants because of its ability to create precise and durable parts from biocompatible materials that can withstand the mechanical and physiological stresses of the spine. However, the design and production of spinal implants require not only compliance with regulatory requirements, such as the FDA’s premarket approval or clearance, but also consideration of the complex biomechanics and ergonomics of the spine, as well as the patient’s age, sex, and act

Conclusion

CNC machining for medical purposes differs from other industries in terms of regulatory compliance, material selection, and design requirements. CNC machining for medical purposes requires specific expertise, testing methods, and quality control protocols to ensure patient safety and efficacy. This article has provided an overview of these differences and presented two case studies of CNC machining for medical devices and implants to illustrate the challenges and opportunities in this field. CNC machining for medical purposes is a vital part of the healthcare industry, enabling the creation of innovative and personalized solutions for patients’ needs.

If you are looking for a partner in CNC machining manufacturer for medical purposes, look no further than our company. We specialize in producing high-quality parts and components for medical devices and equipment. Contact us today to learn more about our services.