Medical silicone injection molding service occupies a pivotal position in the modern medical field. As a high-performance material, medical silicone, with its unique physical and chemical properties, provides excellent solutions for the manufacturing of medical devices and equipment. Longsheng is equipped with all kinds of professional silicone products testing equipment, to provide professional quality control for your products, to meet your customized needs. In this tailored guide, we will explore the ease of silicone injection molding, demonstrate its strengths and highlight the key factors manufacturers should consider.

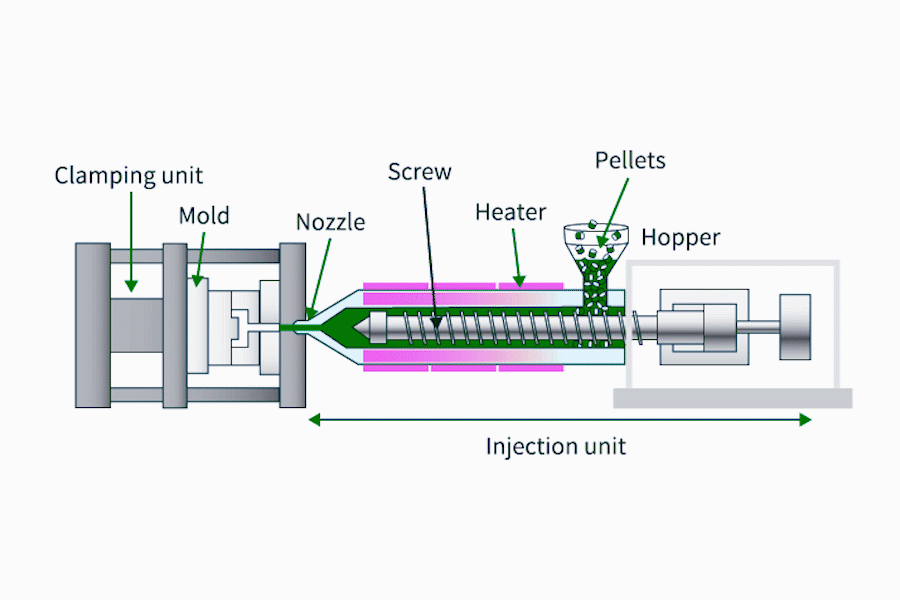

Silicone injection molding is an economical and widely used industrial process, mainly used to manufacture various silicone products. The preheated silicone material is injected into the mold, in which the syringe machine solidifies and forms the desired plastic product.

Process flow of injection molding

This is an extremely complex process, and each stage requires great care. It can be divided into nine key steps, and now, let’s enter the ocean of knowledge of the main processes of silicone injection molding.

Step 1 Select the appropriate liquid silicone raw material

The selection of liquid silicone material should be based on the use, nature, shape and other comprehensive evaluation of the product, to choose the appropriate liquid silicone variety. For example, the medical industry should choose the medical grade silicone material.

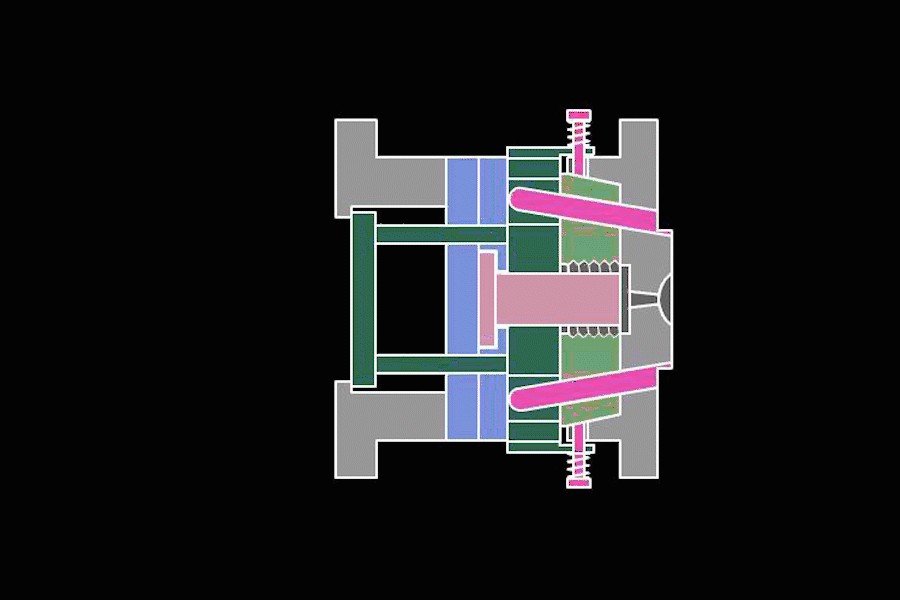

Step 2: Mold design

Mold design is a key step, the design of the mold should take into account the product shape, size, wall thickness, surface requirements and other factors, scientific and reasonable design, to ensure the good performance of the product.

Step 3 Measurement ratio of liquid silicone

When processing liquid silica gel, although appropriate reaction inhibitors have been added to the adhesive material, if the storage conditions are not appropriate, it may still lead to the vulcanization of some rubber at room temperature. Therefore, the liquid silica gel is usually divided into two combined components, one containing a catalyst and the other containing a crosslinking agent, solidified through AB two groups of silica gel in a specific ratio, generally in a ratio of 1:1 ratio.

Step 4 Refining the silica gel raw material

Silica gel, cross-linking agent, solvent and other raw materials are closely refined to ensure uniform composition and no color.

Step 5 Heat the silicone raw material

The raw material is added to the injection molding machine for heating to control the temperature and time.

Step 6:squeeze the liquid silica gel into the mold

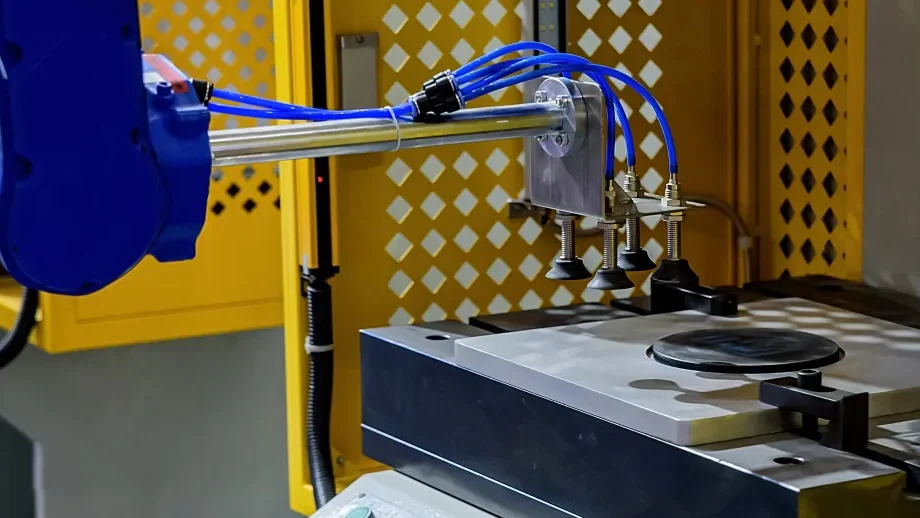

The selected liquid silica gel adhesive material is injected into the injection molding machine, and the liquid silica gel is squeezed into the mold through the pressure of the compressor.

Step 7 is the injection molding

Injection in the mold to ensure uniform injection through pressure control.

Step 8 cooling and removal

Remove the mold and remove the mold after the temperature drops.

Step 9 for subsequent processing

Such as removing the mold head, cleaning the mold, etc.

Medical silicone injection molding service application

Its various functional properties make it a popular choice for various medical devices. Examples of medical devices that can be manufactured using a silicone injection service are as follows:

| application area | explanation |

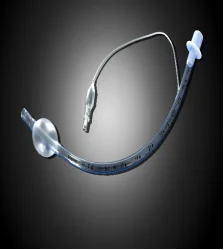

| Medical tubes | Medical tubes made by silicone injection are highly flexible and have excellent puncture resistance, making it an ideal choice for a variety of medical procedures. |

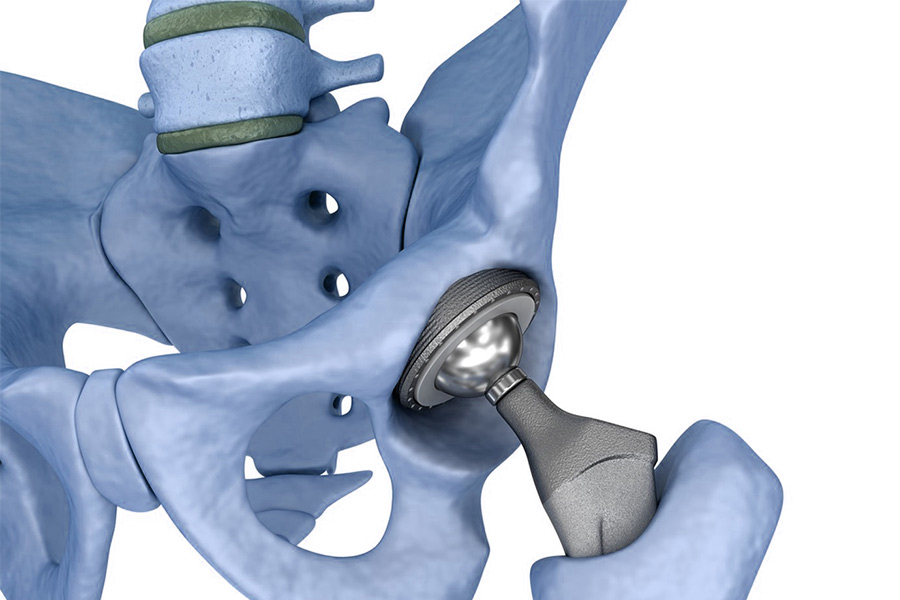

| Implants | Silicone implants are widely used in a variety of medical procedures, including breast augmentation, hip replacement, and dental implants. The biocompatibility and durability of silicone makes it an ideal material for implants. |

| Medical tubes | Medical tubes made by silicone injection are highly flexible and have excellent puncture resistance, making it an ideal choice for a variety of medical procedures. |

| Medical seals | Silicone seals are used in medical equipment to prevent leakage and contamination.The ability to produce complex seals by silicone injection molding makes them a preferred choice for manufacturers. |

Key factors in injection molding services

Quality standardization

- Medical devices must meet strict quality standards, and the manufacturer must ensure that their suppliers meet these standards.

Regulatory Compliance

- Medical device manufacturers must comply with various regulations such as FDA and ISO, and silicone injection service providers must also be able to meet these requirements.

Material selection rationality

- Medical products must be made of high-quality materials that are safe for human use, and silicone injection molding service providers must comply with certain material selection criteria.

Manufacturing capability

- Medical device manufacturing requires high production capacity, and manufacturers must select suppliers that can meet their production needs

Advantages of injection molding service

Biocompatibility

Medical silicone itself has good biocompatibility and does not cause allergy or rejection reaction when contacted with human tissues. The injection molding service can ensure that the silicone maintains its original biocompatibility during the molding process, thus ensuring the safety and reliability of medical silicone products

Flexibility

Medical silicone products have good flexibility and can adapt to the curves and changes of the human body. Injection molding service can accurately control the molding process of silicone, thus ensuring that the product has the desired flexibility and shape needed to better adapt to the needs of the human body.

Antimicrobial

medical silicone products are not easy to breed bacteria on the surface, have a certain antibacterial ability, help to reduce the risk of infection. Injection molding service can add antibacterial agents in the production process to further enhance the antibacterial properties of the product.

High temperature stability

medical silicone products usually need to be used in high temperature environment, while injection molding medical silicone can be used in a range of-60℃ to 250℃ for a long time, and has excellent heat resistance. This makes the injection molding service an ideal choice for manufacturing medical silicone products.

Corrosion resistance

injection molding medical silicone can be used in a strong acid, strong alkali and oxidant environment for a long time, and is not susceptible to corrosion. This corrosion resistance allows medical silicone products to maintain their performance and stability in a variety of complex environments.

Good surface quality

the injection molded parts can obtain good surface quality directly from the mold, reducing or eliminating the subsequent surface treatment process. This is very important for the appearance quality and functional performance of medical silicone products.

We are waiting for your design model in Longsheng

Conclusion

Medical Silicone Injection Molding Services are becoming increasingly important to the healthcare industry as demand for high-quality medical devices continues to rise. Longsheng provides professional custom Injection Molding service, helping medical device manufacturers to produce high-quality custom components that meet regulatory and quality standards.

At Longsheng, we combine cutting-edge technology, strict quality standards, and regulatory compliance to provide a complete solution for medical silicone injection molding services. Whether you’re looking to produce implants, tubing, or seals, we have the expertise and state-of-the-art equipment to deliver the results you need.

FAQs

How to deal with the sintering phenomenon of medical silicone injection molding products?

The sintering phenomenon is usually caused by the high temperature or the long duration of the silicone in the mold. To solve this problem, attempts can be made to reduce the mold temperature, shorten the residence time of silicone in the mold, or adjust the formula of silicone to reduce its sintering sensitivity.

How to deal with the difficulty of demolding medical silicone injection products?

The mold release difficulty may be caused by the unreasonable mold design, the strong adhesion between the silica gel and the mold, or the silica gel has not been fully solidified. To address this issue, attempts can be made to optimize mold design, use a release agent to reduce adhesion, or to ensure that the silicone is fully cured before release.

How to ensure the dimensional accuracy of medical silicone injection molding products?

Size accuracy is one of the important indexes of medical silicone injection molding products. In order to ensure the dimensional accuracy, the formula of silica gel, the injection process parameters and the accuracy of the mold need to be strictly controlled. In addition, regular maintenance and calibration of injection molding equipment and molds is also the key to ensure dimensional accuracy.