The aim of this evaluation is to make clear the elemental and sensible variations between milling and welding. By evaluating and contrasting these two processes, we purpose to supply a complete understanding of their distinctive traits, purposes, and impacts on varied industries. This evaluation may also assist to determine the longer term tendencies and developments in each fields.

On this comparative evaluation, we’ll delve into the distinct manufacturing processes: milling and welding. We are going to discover their definitions, historic improvement, varieties, tools, and know-how used, in addition to their purposes throughout varied industries.

What’s Milling?

Milling is the method of machining utilizing rotary cutters to take away materials by advancing a cutter right into a workpiece. This course of could also be finished by various instructions on one or a number of axes, cutter head pace, and strain. Milling covers all kinds of various operations and machines, on scales from small particular person parts to giant, heavy-duty gang milling operations. It is without doubt one of the mostly used processes for machining customized parts to specific tolerances.

Varieties of Milling

Primarily based on the search outcomes, the sorts of milling operations embody:

- Plain Milling: Includes the creation of a flat horizontal floor parallel to the cutter’s axis utilizing a plain milling cutter.

- Face Milling: Produces a flat floor perpendicular to the cutter’s axis.

- Finish Milling: Produces slots and pockets.

- Turret Milling: Makes use of a turret mill for varied milling operations.

- Horizontal Milling: Holds and rotates the spindle within the horizontal orientation to take away materials from the floor of a stationary workpiece.

- Vertical Milling: Removes materials from flat and vertical surfaces of a workpiece.

- Common Milling: Gives versatility in machining operations and may carry out each vertical and horizontal milling.

- Dro Milling: Makes use of a digital readout (DRO) system for exact milling operations.

- CNC Milling: Managed by a pc numerical management system and a G-code program, permitting for broad functionality machining.

- Tracer Managed Milling: Includes the usage of a tracer to regulate the milling operation.

- Omniversal Milling: Supplies a variety of machining capabilities for varied milling wants.

- Profile Milling: Used for creating advanced shapes and profiles on the workpiece.

- Planetary Milling: Includes the usage of planetary movement for milling operations.

- Drum Milling: Makes use of a drum milling machine for particular milling necessities.

- NC/CNC Milling: Incorporates numerical management for exact and automatic milling operations.

Milling Tools and Expertise

Milling tools and know-how embody a big selection of equipment and processes which can be integral to the milling trade. Listed here are some key insights into milling tools and know-how:

Tools: Milling isMilling tools and know-how have advanced over time to satisfy the calls for of varied industries and obtain exact machining outcomes. Listed here are some key factors about milling tools and know-how:

- Milling is carried out with a milling cutter, which is held within the spindle of a milling machine. The cutter can take varied varieties and is used to take away materials from the workpiece.

- Milling machines might be categorised based mostly on their orientation, similar to vertical and horizontal milling machines. Different classifications embody methodology of management, dimension, objective, and energy supply.

- The event of milling machines has seen developments in energy sources, from human and animal forces to water, wind, and steam machines.

- Trendy milling machines, particularly these outfitted with pc numerical management (CNC), supply elevated effectivity, accuracy, and security. CNC milling machines can deal with a variety of designs, dimensions, and supplies.

- Milling tools is used for varied purposes, together with crushing, grinding, and shaping completely different supplies. Industries similar to feed, meals, prescribed drugs, and mining make the most of milling tools like hammer mills, curler mills, ball mills, agitated media mills, jet mills, and classifier mills.

- The collection of milling tools will depend on components similar to the kind of materials being processed and the specified particle dimension.

- Milling processes contain setup time, cycle time, and cargo/unload time. The setup time consists of making ready the milling machine, planning device actions, and putting in fixtures. The cycle time refers back to the time required to finish every half, whereas the load/unload time includes securing the workpiece and eradicating the completed half.

Purposes and Industries Using Milling

Milling is utilized throughout a various vary of industries and performs a pivotal position within the manufacturing of varied merchandise. Listed here are some key purposes and industries using milling:

Aerospace and Shipyard Industries: Pocket milling, a broadly used operation in machining, is extensively employed in these industries for eradicating materials inside an arbitrarily closed boundary on a flat floor of a workpiece to a set depth. This course of is essential for the manufacturing of high-value, light-weight, and complicated parts for flight-engineered merchandise, together with airframe parts, controls, flight-surface actuator parts, jet parts, and rocket-engine parts.

Medical and Surgical Software Manufacturing: Milling is extensively used within the manufacture of surgical instruments and medical implants. The flexibility to course of a variety of biocompatible and simply sterilized supplies with excessive precision and repeatability is extremely valued in these high-value purposes.

Manufacturing, Oil & Gasoline, and Infrastructure: These industries additionally make the most of milling for varied purposes, benefiting from the power to regulate the particle dimension of merchandise, take away contamination or water/moisture from bulk supplies, and produce dry particles earlier than transport. The milling course of permits for the manufacturing of parts utilized in restricted portions, prototypes, and tooling for different processes.

Common Manufacturing: Milling is used for making varied sorts of gears, producing slot or groove in workpieces, machining flat and irregular surfaces, and creating advanced shapes. Additionally it is employed in establishments or faculties to conduct lab assessments on milling machines.

What’s Welding?

Welding is an operation whereby two or extra parts are united via warmth or strain or each. It’s used on metals, thermoplastics, and typically wooden. Welding includes the applying of warmth, strain, or each to fuse two parts, and it’s a fabrication course of that requires a excessive talent degree and sensible data of topics like physics, chemistry, and metallurgy. The method of welding can be utilized to completely be a part of two related metals collectively, and it’s a vital construction-related exercise that’s usually used for binding supplies collectively by means of the applying of warmth. The welding course of includes varied varieties and strategies, similar to arc welding, MIG welding, TIG welding, and stick (guide steel arc) welding, every with its personal distinctive traits and purposes. Total, welding is a elementary course of for becoming a member of supplies and performs an important position in varied industries and purposes.

Varieties of Welding

Primarily based on the data from the search outcomes, there are a number of sorts of welding processes, every with its personal traits and purposes. Listed here are a few of the fundamental sorts of welding:

MIG Welding (GMAW): This is without doubt one of the simpler sorts of welding for learners to study. It includes utilizing a skinny wire as an electrode, which heats up as it’s fed by means of the welding instrument and in the direction of the welding web site. Shielding fuel have to be used to guard the weld from contaminants within the air 1.

TIG Welding (GTAW): Gasoline Tungsten Arc Welding, also called TIG welding, makes use of a non-consumable tungsten electrode to provide the weld. This course of is understood for its precision and is often used for welding skinny sections of stainless-steel and non-ferrous metals similar to aluminum, magnesium, and copper alloys.

Stick Welding (SMAW): Shielded Metallic Arc Welding, or stick welding, is a guide arc welding course of that makes use of a consumable electrode coated in flux to put the weld. It’s generally used for welding iron and metal, and it’s typically used outdoor or in drafty situations.

Flux Cored Arc Welding (FCAW): This course of makes use of a tubular wire full of flux because the electrode, eliminating the necessity for an exterior shielding fuel. It’s generally utilized in development and shipbuilding because of its excessive welding pace and portability.

Welding Tools and Expertise

Welding tools and know-how embody a big selection of equipment, processes, and developments that play an important position in varied industries. Listed here are some key insights from the search outcomes:

Tools and Expertise: Welding tools and know-how from firms like Lincoln Electrical and R-Tech supply a variety of welding machines with easy-to-use options, distinctive worth, and strong development. These machines make the most of the most recent ultra-reliable inverter energy parts sourced from American and German firms, offering excessive responsibility cycles and nice reliability. The tools consists of parts originating from a number of international locations, and the primary a part of the inverter vary makes use of IGBT and energy modules produced by American and German firms. Welding Expertise Corp, based mostly within the USA, presents welding controls, electrical panels, and full load take a look at stations for validation and high quality acceptance, assembly ISO 9001:2000 requirements and AS9100 Aerospace High quality System Customary.

Industrial Purposes: Welding know-how has purposes in varied industries, together with aerospace, medical, vitality, electronics, automotive, manufacturing, development, and extra. Developments in welding know-how have led to the event of processes like laser welding, which is outstanding within the automotive trade for enhancing productiveness at a low value when welding automotive parts similar to roof, door, or filler assemblies.

Prices and Developments: The price of welding performs an important position in manufacturing selections, with variables similar to tools value, labor value, materials value, and vitality value impacting the entire value. Totally different welding processes have various tools prices, from cheap strategies like shielded steel arc welding and oxyfuel welding to costly strategies like laser beam welding and electron beam welding, that are utilized in excessive manufacturing operations.

Purposes and Industries Using Welding

Welding is a flexible course of with purposes throughout a variety of industries. Listed here are a few of the key purposes and industries using welding:

Aerospace and Transportation Industries: Welding performs an important position within the development of airplanes, spacecraft, and different transportation sectors. Gasoline Tungsten Arc Welding (GTAW) is employed within the development of airplanes and different transportation sectors, the place the precision of GTAW works effectively with aluminum and unique alloys used to scale back weight and gasoline consumption. Practically 95% of NASCAR racecars are welded by hand utilizing the GTAW course of, highlighting its significance within the automotive trade.

Development Trade: Welding applied sciences are broadly used within the development trade for the fabrication of structurally sound steel frameworks by fusing varied steel parts. Additionally it is used to create and preserve non-structural parts. Welding is essential in constructing development, industrial development, and infrastructure initiatives, overlaying a broad and numerous vary of buildings and purposes.

Manufacturing and Fabrication: Welding is important within the manufacturing trade for assembling advanced equipment and fabricating intricate parts that may be unattainable to provide by means of different means. It’s broadly used for the fabrication of strain vessels, bridges, constructing buildings, plane and spacecraft, railway coaches, and common purposes moreover shipbuilding, car, electrical, digital, and protection industries.

Automotive Trade: Welding is extensively used within the automotive trade for varied purposes, together with automotive repairs, manufacturing of tanks, strain vessels, and pipes. Laser beam welding, which gives concentrated warmth perfect for slim, deep welds and excessive becoming a member of charges, is definitely automated and ideal for high-volume purposes throughout the automotive trade.

Different Industries: Welding finds purposes in quite a lot of different industries, together with shipbuilding, meals processing, prescribed drugs, telecommunications, oil and fuel, and extra. It’s used for becoming a member of items of steel collectively and is a really expert commerce, with various kinds of welding catering to particular wants in varied industrial purposes.

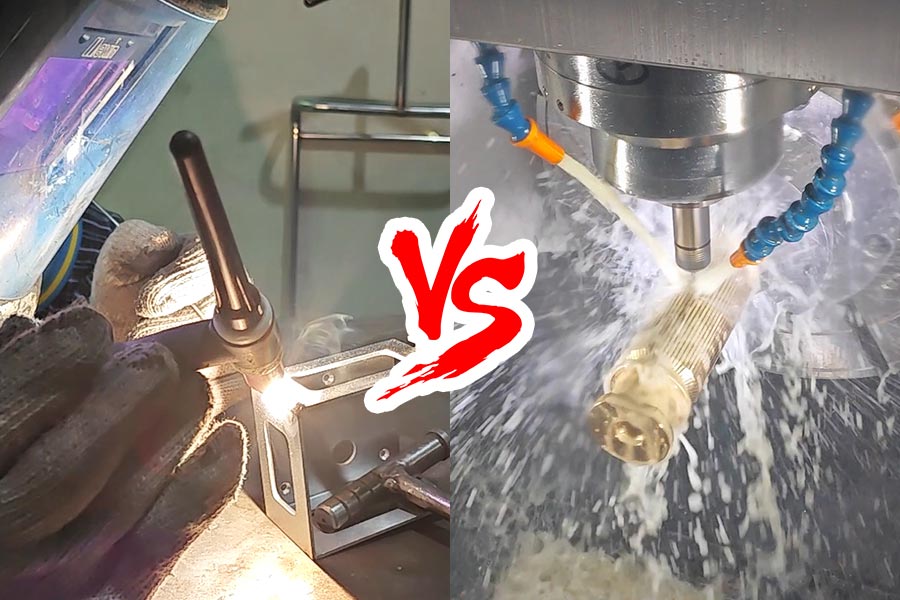

Evaluating Milling and Welding

Here is a comparability of milling and welding in a tabular format:

| Milling | Welding | |

|---|---|---|

| Similarities | Each are integral to manufacturing and fabrication, providing completely different functionalities and purposes for distinctive functions in varied industries. | Each are integral to manufacturing and fabrication, providing completely different functionalities and purposes for distinctive functions in varied industries. |

| Basic Variations | Milling includes reducing the steel to form or kind it into a particular form. | Welding is used to hitch separate items of steel collectively, creating a powerful and sturdy bond between the supplies. |

| Sensible Variations in Purposes | Milling is primarily used for shaping and forming steel workpieces by eradicating extra materials. | Welding is used to hitch separate items of steel collectively, creating a powerful and sturdy bond between the supplies. |

| Tools Variations | Milling tools sometimes includes the usage of reducing instruments to take away materials from a workpiece. | Welding tools encompasses a variety of equipment and instruments designed for becoming a member of steel parts by means of the applying of warmth and strain. |

| Technological Advances | Technological advances in milling have led to the event of superior equipment and instruments, resulting in extra environment friendly and exact milling processes. | Technological advances in welding have led to the event of superior equipment and instruments, enhancing the effectivity and high quality of welding processes. |

Please be aware that this desk gives a high-level comparability of milling and welding. The specifics can fluctuate based mostly on the kind of milling or welding course of getting used, the supplies concerned, and the particular utility or trade.

Case Research

Here is a comparability of milling and welding within the automotive and development industries, together with a comparative evaluation of each processes in related industries:

| Milling | Welding | |

|---|---|---|

| Automotive Trade (Case Research) | Milling is used extensively within the automotive trade to form and kind steel parts with excessive precision. This consists of parts like engine blocks, gears, and different intricate parts. | Welding, significantly Friction Stir Welding (FSW), is used within the automotive trade to hitch parts collectively. FSW is a solid-state course of that joins two going through surfaces, utilizing much less warmth than different welding strategies, which might be useful in automotive manufacturing the place weight and vitality effectivity are vital concerns. |

| Development Trade (Case Research) | Milling will not be sometimes a major course of within the development trade. Nonetheless, it may be used within the manufacturing of particular parts or parts utilized in development equipment or tools. | Welding is a elementary course of within the development trade, used within the development of buildings, bridges, pipelines, and different engineering gadgets needed for infrastructure in city environments. Varied welding processes are used, together with arc welding, laser reducing and welding, laser-arc hybrid welding, friction applied sciences, and electron beam welding. |

| Comparative Evaluation in Related Industries | Milling is primarily utilized in industries the place precision and the power to create advanced shapes are needed, similar to automotive, aerospace, and manufacturing industries. | Welding is used throughout a variety of industries, together with development, automotive, aerospace, and manufacturing, the place the becoming a member of of particular person parts is important for structural integrity and performance. |

Please be aware that this desk gives a high-level comparability of milling and welding in particular industries. The specifics can fluctuate based mostly on the kind of milling or welding course of getting used, the supplies concerned, and the particular utility or trade.

How to decide on between milling and welding?

Selecting between milling and welding will depend on quite a lot of components, together with the particular necessities of the duty, the supplies concerned, the out there tools and abilities, and the specified outcomes. Listed here are some key concerns:

Nature of the Process:

- If the duty includes shaping or forming a steel workpiece by eradicating materials, then milling can be the suitable selection. Milling is a cloth elimination course of that may produce exact and complicated shapes.

- If the duty includes becoming a member of separate items of steel collectively, then welding can be the suitable selection. Welding is a course of that makes use of warmth and strain to create a powerful and sturdy bond between steel parts.

Supplies Concerned:

- The kind of materials can even affect the selection between milling and welding. Some supplies could also be extra appropriate for milling, whereas others could also be extra appropriate for welding. For example, arduous and brittle supplies could also be harder to weld, whereas delicate and ductile supplies could also be harder to mill.

Accessible Tools and Expertise:

- Milling requires a excessive degree of talent and experience to function the milling machine successfully, choose the right instruments, and produce correct outcomes. Then again, welding requires talent, however even inexperienced customers can simply study and carry out primary welding duties.

- Milling machines are sometimes giant items that require loads of house, make a substantial mess, and want common upkeep. Welding tools, alternatively, is extra moveable and might be carried simply with the manufacturing course of.

Desired Outcomes:

- If the specified final result is a exact and complicated form, then milling can be the suitable selection. If the specified final result is a powerful and sturdy bond between separate items of steel, then welding can be the suitable selection.

CNC Milling vs. Welding: The right way to Select the Proper Approach for Your Undertaking

Selecting between milling vs. Welding totally will depend on the design and venture specs. In spite of everything, it’s all about acquiring the useful and dimensional necessities within the ultimate product.

At LongSheng, We offer complete CNC machining providers, together with CNC milling, turning, routing, and drilling. Now we have intensive expertise in dealing with CNC initiatives for numerous industries. Our providers prolong from speedy prototyping to customized machining on your distinctive wants.

Selecting us on your machining initiatives ensures pace, precision, and high quality with a customer-centric strategy. Our knowledgeable engineers and operators steadiness value and high quality with each machined half. So, add your design file and get an prompt quote to start out your venture!

Conclusion

The implications of selecting between CNC milling and welding are vital, as they instantly impression the standard, precision, and performance of the ultimate product. The selection of method influences the structural integrity, dimensional accuracy, and general efficiency of the manufactured parts. Moreover, the collection of the suitable methodology can have an effect on manufacturing prices, lead instances, and the general effectivity of the manufacturing course of.the choice to decide on between CNC milling and welding ought to be based mostly on an intensive evaluation of the venture necessities, materials traits, and the experience of the provider. Each methods supply distinctive benefits and are suited to particular purposes. By rigorously contemplating these components, it is attainable to make an knowledgeable choice that aligns with the venture’s aims and ensures the profitable realization of the specified outcomes.

Your blog is a beacon of positivity, uniting like-minded people in a harmonious community.