Powder Coating Services

Powder coating is available in a wide range of colors and finishes, allowing for customization to meet aesthetic preferences and functional requirements.

Powder Coating Specifications

| Materials | Colors | Glossiness | Thickness | Texture | Applications |

|---|---|---|---|---|---|

| Aluminum, Steel, Stainless steel | Black, White, any RAL code or Pantone number |

Glossy (Above 60 gu) Matte (Below 20 gu) | 40μm to 140μm | glossy, matte, textured, and metallic finishes | automotive, architecture, aerospace, and electronics |

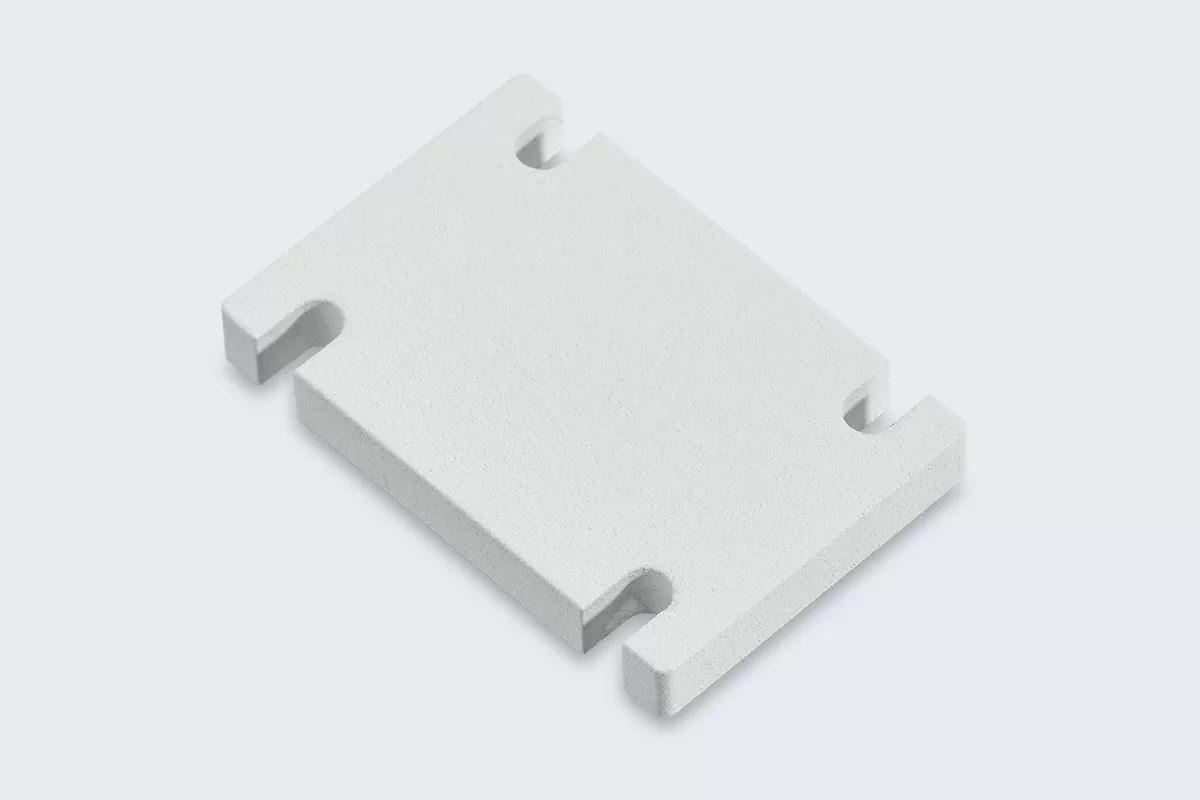

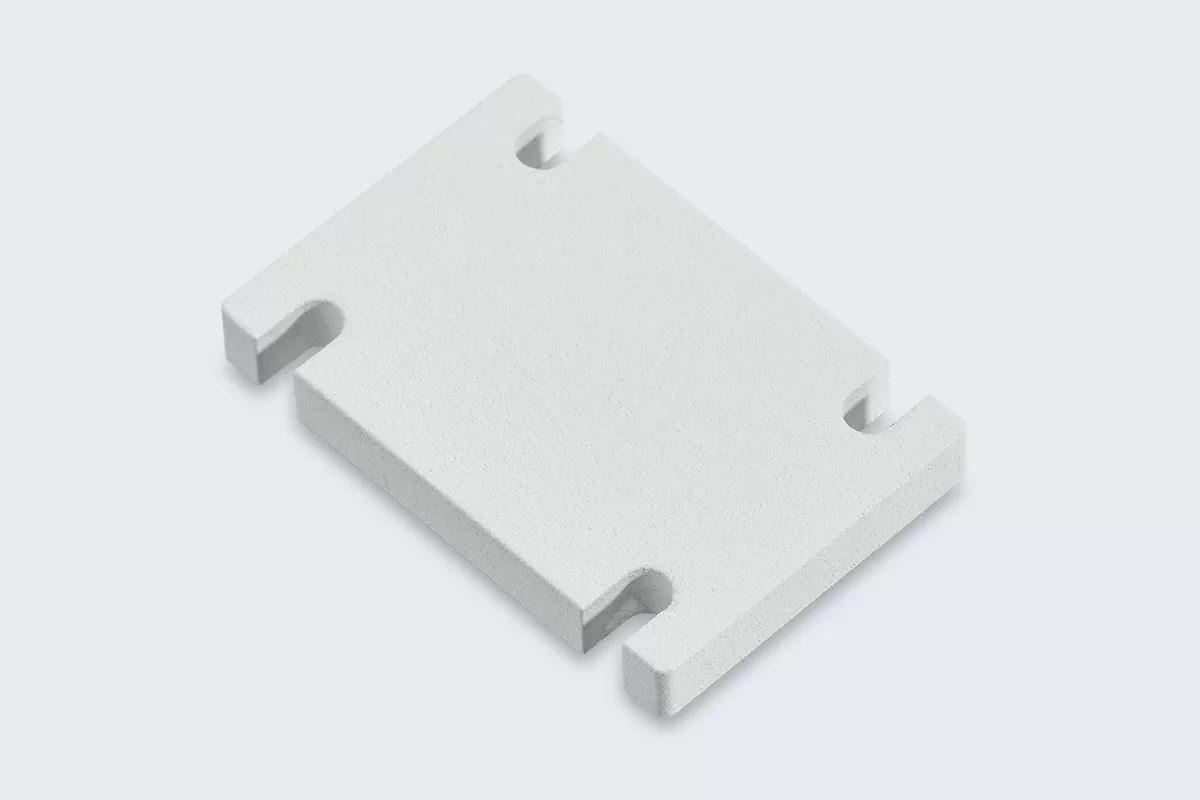

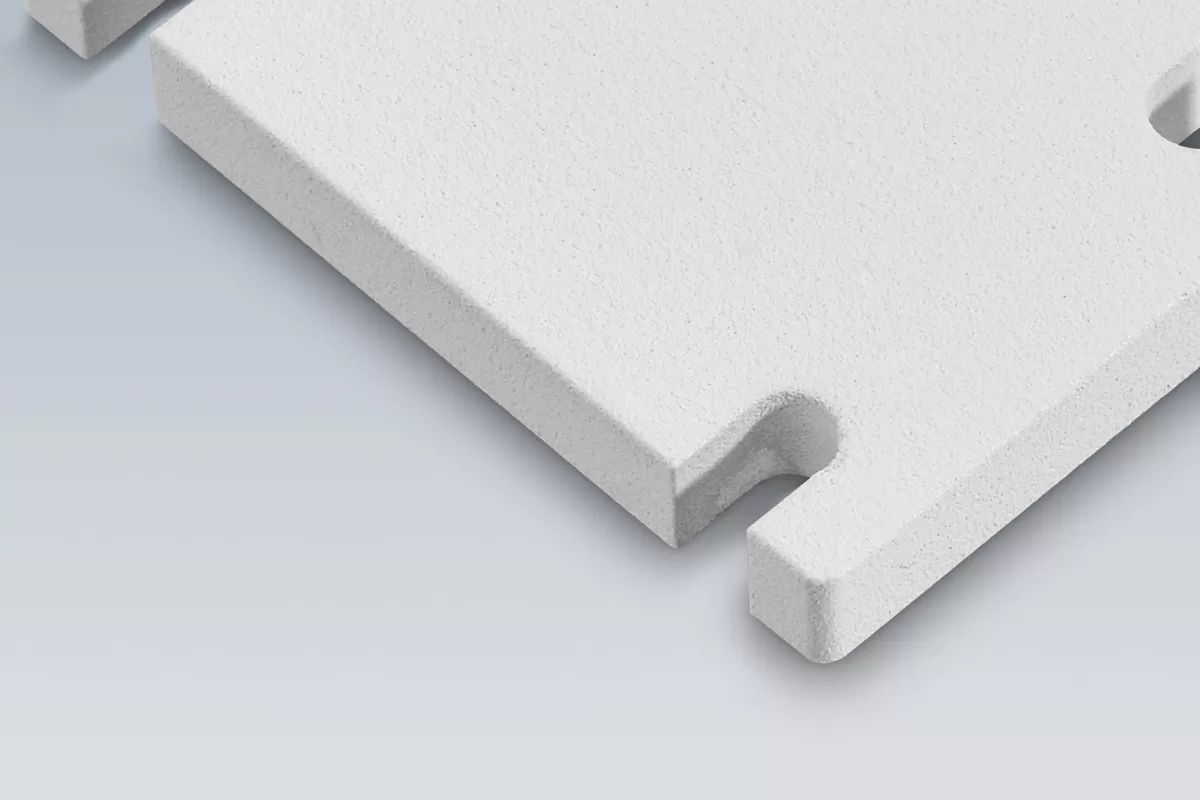

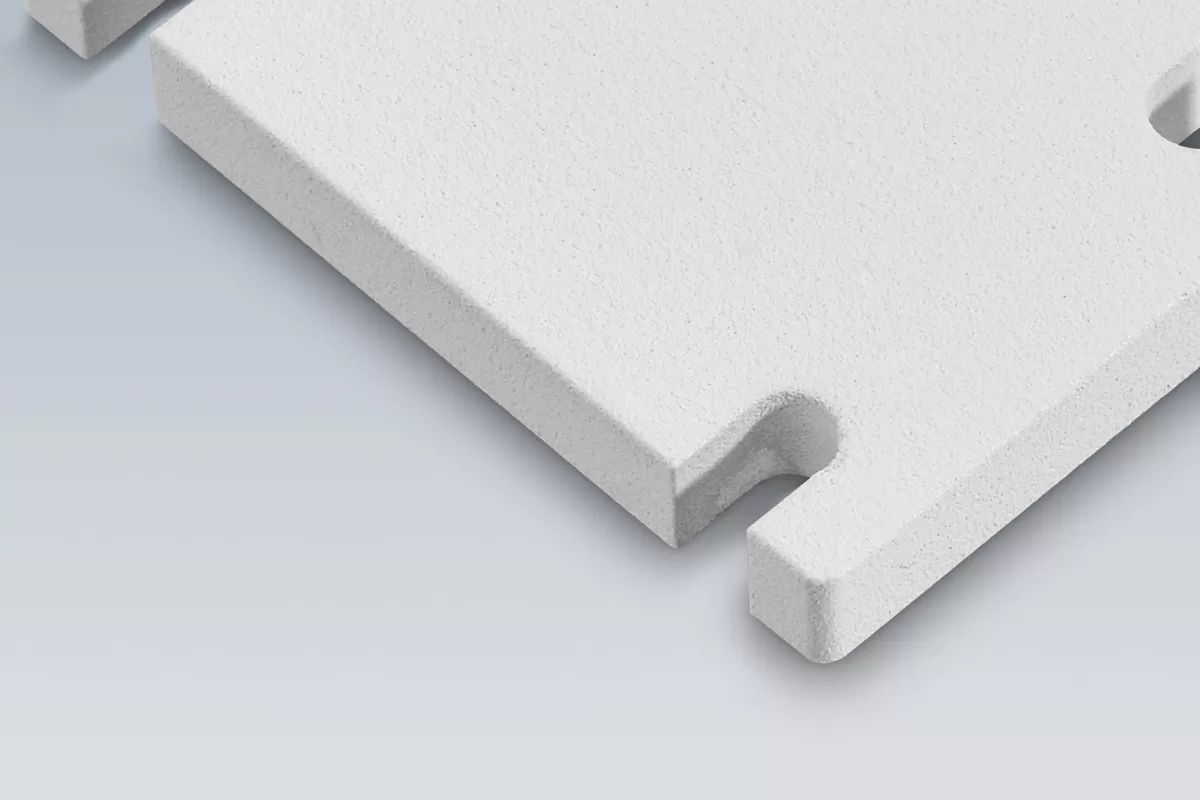

Example of a powder coating parts

About Powder Coating

Powder coating involves applying a dry powder to the surface of the object to be coated. The powder consists of finely ground particles of pigments and resins.

Powder coating offers several advantages over traditional liquid paint, including superior durability, resistance to chipping, scratching, and fading, as well as better chemical and corrosion resistance. It also produces a uniform and smooth finish with no drips or runs.

Design considerations for powder coating

Hanging and Jigging Marks: When designing for powder coating, consider that parts are hung on racks or jigs, which may leave marks. Plan your part placement accordingly and specify areas where marks are acceptable in technical drawings.

Masking: Clearly indicate in your CAD file which areas should be masked or plugged to protect critical surfaces like threaded holes. Discuss masking requirements with your coating service.

Tolerances: Ensure parts meet required tolerances before coating. Discuss tolerance considerations with your design team and coating service provider.

- Communication: Maintain open communication with your coating service provider to address specific requirements, material considerations, and any challenges related to your parts.

Put your parts into production today

- All information and uploads are secure and confidential.