Introduction to CNC Machining

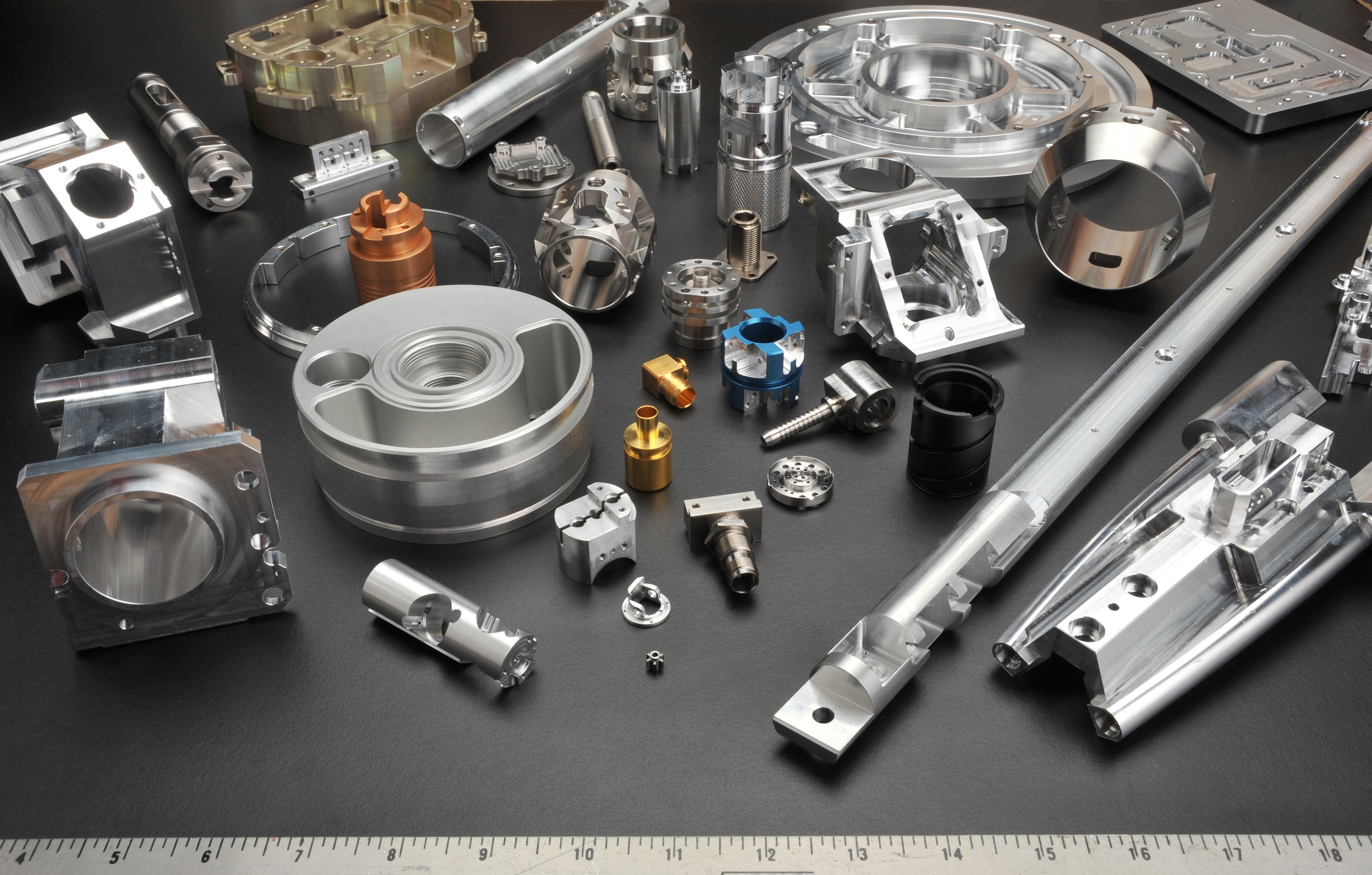

CNC machining allows manufacturers to create intricate and highly precise parts using various materials, including aluminum, plastic, and titanium. By leveraging computer-controlled tools, high precision CNC machining achieves tight tolerances and consistent results, making it invaluable for sectors such as aerospace, automotive, and medical industries.

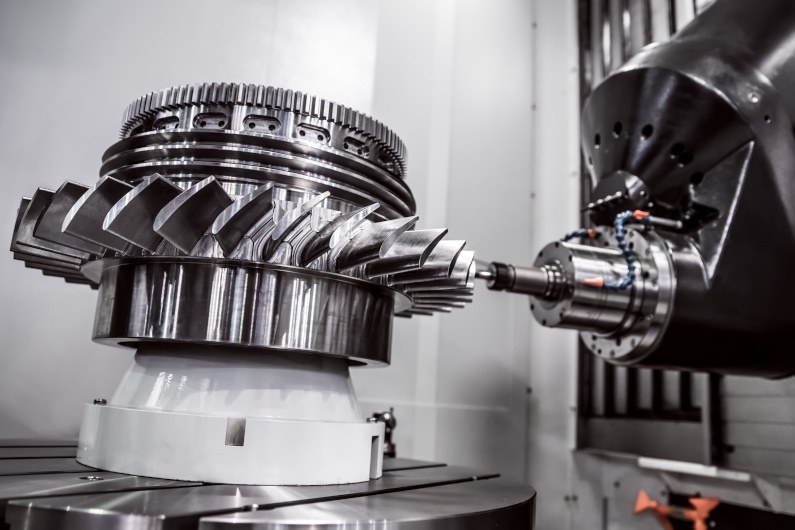

Multi-Axis CNC Machining for Complex Parts

Multi-axis CNC machining offers unparalleled versatility, allowing cutting tools to move in multiple directions to shape complex geometries. This reduces the need for multiple setups, improves efficiency, and enhances part accuracy. Components that were previously impossible to manufacture with traditional 2 or 3-axis machines are now achievable through 4-axis or 5-axis CNC setups.

Material Selection for CNC Machining

- Aluminum CNC Machining: Aluminum is a top choice in industries where weight and corrosion resistance are key. This material is often used in automotive parts, aerospace components, and consumer electronics due to its excellent machinability and affordability.

- Keywords: aluminum CNC machining

- CNC Plastic Machining: CNC machines can also process plastics such as ABS, polycarbonate, and nylon. CNC plastic machining is ideal for producing lightweight, non-conductive parts for electronics, medical devices, and prototypes.

- Keywords: CNC plastic machining

- CNC Titanium Machining: Titanium is known for its strength and resistance to extreme temperatures. CNC titanium machining is critical for manufacturing aerospace and medical components that require both strength and biocompatibility.

Advantages of Precision CNC Machining

- Tight Tolerances: CNC machining achieves extreme accuracy, essential for precision CNC machining parts in sectors like aerospace, where reliability and performance are critical.

- Reduced Lead Times: CNC machining parts factories can produce high volumes of intricate parts faster with minimal human intervention, reducing time-to-market for complex designs.

Applications in Different Industries

CNC machining is used across multiple industries to produce precision components:

- Aerospace: Aircraft engine parts, landing gear components

- Automotive: Engine blocks, transmission housings

- Medical: Surgical instruments, implantable devices

Conclusion: Why CNC Machining is Essential for Complex Manufacturing

The use of multi-axis CNC machining and diverse materials like aluminum, plastic, and titanium ensures that manufacturers can produce intricate, high precision CNC machining parts at scale. CNC machining continues to be a critical technology for achieving efficiency, accuracy, and versatility in manufacturing.

Disclaimer

The content appearing on this webpage is for informational purposes only. LongSheng makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LongSheng’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LongSheng

This article was written by various LongSheng contributors. LongSheng is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

Pingback: CNC Machining Manufacturer, Factory & Workshop: How Top Providers Deliver Precision at Scale

Thank you for another informative website. Where else could I am getting that kind of information written in such an ideal method? I’ve a undertaking that I’m just now running on, and I have been on the look out for such information.

Thank you for your support, each article is written by ourselves, we will update the article every day, you can subscription LS, wish you a happy day.

We absolutely love your blog and find almost all of your post’s to be just what I’m looking for. Would you offer guest writers to write content available for you? I wouldn’t mind composing a post or elaborating on a number of the subjects you write related to here. Again, awesome web site!

You should take part in a contest for one of the best blogs on the web. I will recommend this site!