Have you ever thought of a small detail that plays a vital role in our lives? For example, in automobile manufacturing, the engine manufacturing needs to master various kinds of casting, forging and other processes, but the most critical is the processing of parts. Precision is always a very important factor for machining high precision parts. Once the accuracy does not meet the requirements, it may lead to a substantial reduction in the efficiency of the entire equipment, resulting in loss. Therefore, it is very necessary to understand the principle and technical requirements of machining high precision parts.

So, what is high precision machining?

High precision machining is actually the ability to achieve very small dimensional tolerances, and surface quality almost to the finish, will not affect the geometry and performance of the product.

Principles of machining high precision parts

High precision parts machining refers to the process of applying precision machining technology to parts or components. It has the characteristics of high precision, high surface quality and high stability. The principle of high precision parts machining mainly includes the following aspects:

Material selection and handling

High precision parts are usually made of chrome-molybdenum steel, tool steel or stainless steel, etc., which need to be processed with special metal materials refining technology to ensure that they can meet the needs of ultra-precision parts processing.

machining technology

The machining of high-precision parts requires the use of ultra-high speed cutting machine tools to ensure that the machining diameter, surface finish and other indicators can meet the requirements. In addition, the use of high-quality tools and fixtures is also an important condition to ensure the quality of processing.

Surface treatment

High precision parts need surface treatment, including polishing, rust prevention, spraying, etc. These treatments can improve the finish and corrosion resistance of the parts, thus ensuring that the parts can maintain good performance during use.

Part design

In the design process of parts, we need to take into account the requirements of production technology and machining accuracy, and work out a design scheme that can meet the requirements.

High precision parts Machining considerations

High precision parts machining is a difficult process, which requires many advanced technologies and equipment to ensure precision and quality. In the process of machining, many factors need to be considered, such as materials, machining procedures and tools.

Material selection:

In the machining of high precision parts, the choice of materials is very important. Different materials have different physical and chemical properties, which can affect the processing process. The commonly used materials are metal, ceramic, plastic and composite materials, etc. Selecting suitable materials can improve the quality and efficiency of processing.

Processing procedure:

Machining program is the key to realize high precision parts machining. In the process of machining, it is necessary to select the appropriate machining mode according to different parts shape and materials. For example, round parts are processed by turning and flat and curved parts are processed by milling. In addition, it is necessary to control the machining parameters precisely to ensure the machining quality.

Tool selection:

In the process of machining high precision parts, the choice of cutting tool is also very important. Different cutting tools are used in different machining processes and have different effects on machining processes. For example, high-speed drills are used to make small holes, and spiral milling cutters are used to make curved parts. Tool size, shape and material selection also need to take into account the actual application scenario, in order to improve the accuracy and efficiency of parts machining.

Precision parts machining technical requirements

In the machining of high precision parts, the requirements of high precision, high quality and high efficiency should be met. In order to achieve these requirements, the following technical capabilities are required:

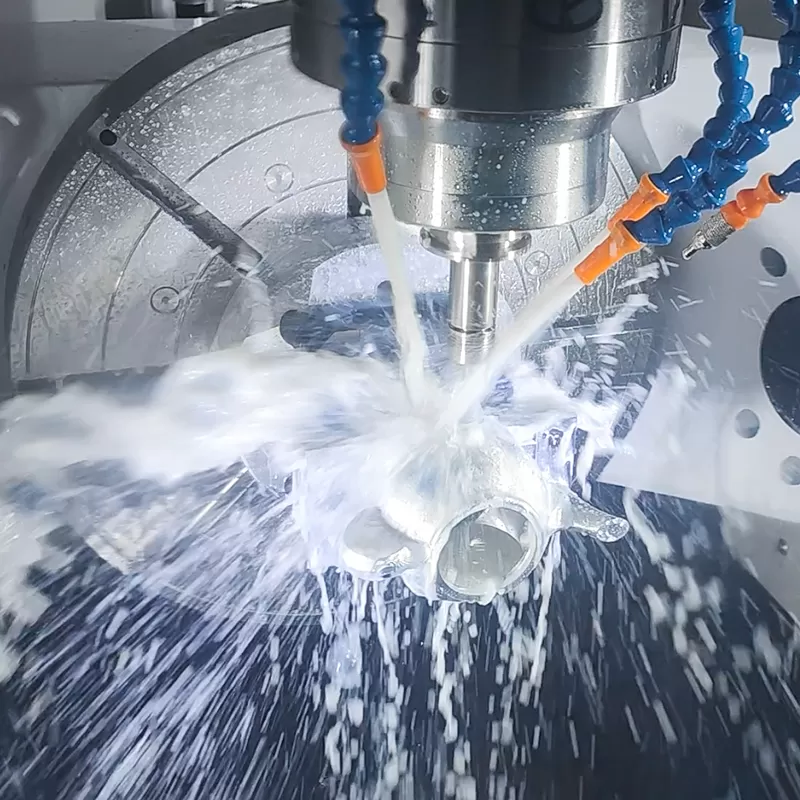

Milling technique

Milling is one of the most commonly used techniques in parts machining. In milling, the tool needs to rotate and move to cut the raw material. CNC Milling technology is widely used in parts processing because it can be used to manufacture parts of various shapes and sizes.

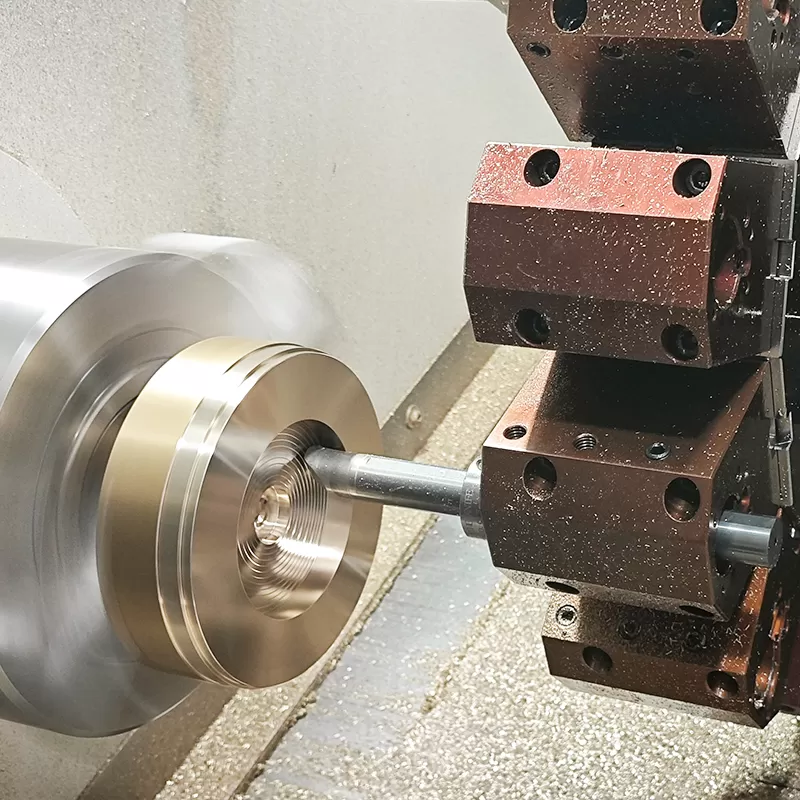

Turning technique

Turning is another common part machining technique. It uses a rotating tool to clamp the workpiece to the workbench and cut from the surface of the workpiece to prepare the part. Some turning machines also allow simultaneous multi-axis machine tools, which can speed up production and improve machining accuracy.

Stamping technology

Metal stamping is a technique for fabrication sheet metal into the desired shape and is one of the important methods for installing and straightening parts. It works by applying high pressure to the plate, causing it to undergo plastic deformation and eventually forming the part into the desired shape.

Edm technology

Edm is a kind of precision machining technology, its main use is to process hard materials, such as tungsten steel, hard alloy and so on. It works by creating a spark on the workpiece, causing the surface to be dissolved by heat, and then using ionized gas to cut the metal particles off the workpiece.

Laser cutting technique

Laser cutting is a common processing technology, it can avoid the influence of thermal and mechanical stress in the process of machining, so it can achieve extremely high precision and quality. Laser cutting can be used to process a variety of materials, including metal, wood, plastic and so on.

Precision parts machining needs strict quality control and precision technology. By using the right technology and carefully controlling multiple parts of the production process, we can produce high quality parts to meet the needs of our customers.

High precision parts machining is becoming more and more important in today’s manufacturing industry. It plays a very important role in improving the quality and stability of products. This paper introduces the principle and technical requirements of high precision parts machining, hoping to help readers understand this field. In the meantime, readers can also follow our blog to learn more about high precision parts machining.