Sheet metal fabrication is a complex process that requires a precise balance of skill, knowledge, and expertise. Whether you are a seasoned professional or a hobbyist, there are always tips and tricks that can help you improve your craft and create metal products that are of the highest quality.

At Longsheng, we specialize in providing custom sheet metal fabrication services that meet the unique needs of our clients. We understand the complexities involved in this process and have developed a wealth of knowledge and experience that we are eager to share with others.

In this article, we will provide you with a comprehensive overview of sheet metal fabrication, including tips and tricks that can help you produce exceptional products that meet your specification and exceed your expectations.

Understanding Sheet Metal Fabrication

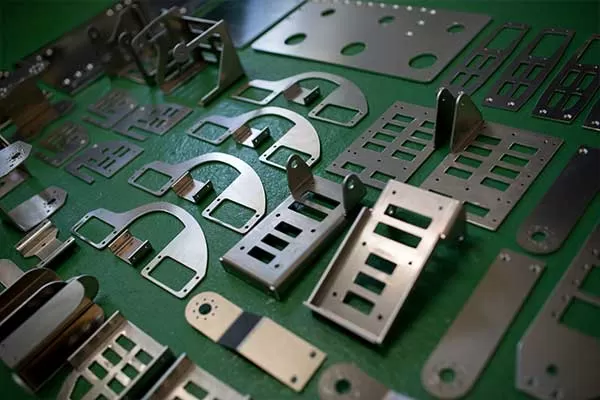

Sheet metal fabrication process that involves shaping and forming sheet metal into the desired shape or product. The process typically begins with the creation of a design or blueprint, which outlines the specifications for the final product.

There are several techniques that can be used to fabricate sheet metal, including cutting, bending, and welding. The selection of the right technique depends on a range of factors, including the type of metal being used, the desired outcome, and the expertise of the fabricator.

Tips for Sheet Metal Fabrication

The following tips can help you improve your sheet metal fabrication skills and produce high-quality products:

Choose the Right Metal

Choosing the right metal is key to creating a quality sheet metal product. The most commonly used metals for sheet metal fabrication include steel, aluminum, and stainless steel. Each metal has its own unique characteristics that can impact the design and fabrication process.

Steel, for example, is strong and durable, but it can be difficult to work with. Aluminum is lightweight and easy to work with, but it may not be as strong as steel. Stainless steel is corrosion-resistant and can be used in harsh environments, but it is also more expensive than other metals.

Use the Right Tools

Using the right tools is essential to performing sheet metal fabrication accurately and efficiently. The tools required will depend on the specific type of fabrication you are performing. For example, a cutting tool may be required to create the initial shape of the metal, while a bending tool may be required to curve the metal into a more complex shape.

It is important to use high-quality tools that have been designed to handle the particular type of metal you are using. Using the wrong tool can result in damage to the metal and compromise the integrity of the final product.

Practice Good Safety Habits

Sheet metal fabrication involves working with heavy machinery and sharp tools. As such, it is important to practice good safety habits to prevent injury. Always wear protective gear, such as gloves, goggles, and earplugs, when working with sheet metal. Additionally, make sure to properly secure the metal in place to prevent it from becoming a hazard.

Follow Design Specifications

It is important to follow the design specifications closely to ensure that the final product meets the desired specifications. Take the time to review the blueprint and make sure that you fully understand the design specifications before beginning the fabrication process.

Additionally, it is important to communicate regularly with the client to ensure that their needs are being met throughout the fabrication process. This can help to prevent misunderstandings and ensure that the final product meets the client’s expectations.

Monitor Quality Control

Quality control is essential to producing a high-quality sheet metal product. Monitor the process closely to ensure that each step is performed correctly and that the final product meets the desired specifications.

Invest in quality assurance software, such as CMM, that can help to automate the quality control process and ensure that the final product meets the highest standards of quality.

Conclusion

Sheet metal fabrication requires a high degree of skill and expertise to produce quality products that meet the unique needs of clients. At Longsheng, we are committed to providing exceptional sheet metal fabrication services that meet the unique needs of our clients.

By following the tips and tricks outlined in this article, you can improve your sheet metal fabrication skills and create high-quality products that exceed your expectations. Remember to choose the right metal, use the right tools, practice good safety habits, follow design specifications, and monitor quality control to produce exceptional sheet metal products.