What is Sheet Metal Stamping?

Sheet metal stamping, also known as pressworking, is a manufacturing process that involves shaping flat sheets of metal into a desired shape or form. This process is used in a variety of industries, including automotive, aerospace, electronics, and construction, among others.

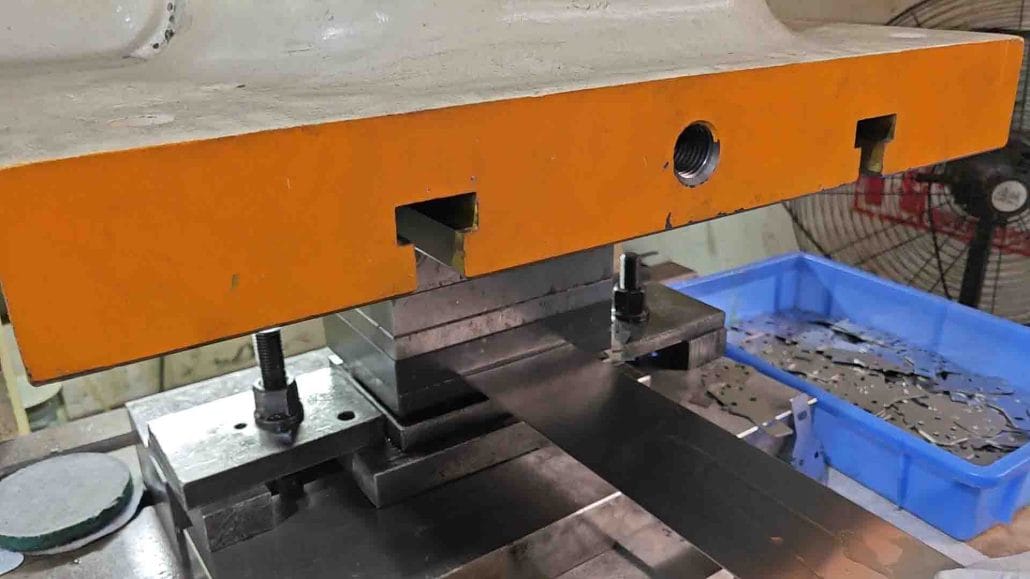

The process of sheet metal stamping involves a press machine that applies pressure to a metal sheet, causing the sheet to bend or deform into the desired shape. The press machine uses a tool, known as a die, which is made up of two parts: a punch and a die. The punch is the part of the die that comes into contact with the metal sheet, while the die is the part that supports the metal sheet during the stamping process.

The sheet metal stamping process can produce a wide range of shapes and forms, including simple flat parts, complex shapes with multiple bends, and intricate designs. The process is also capable of producing high volumes of parts quickly and efficiently, making it a popular choice for mass production.

There are several advantages to using sheet metal stamping for manufacturing. First, the process is highly flexible and can be used to produce a wide range of parts with varying sizes, shapes, and thicknesses. Additionally, sheet metal stamping can produce high-quality parts with tight tolerances, ensuring precision and accuracy in the final product. Finally, sheet metal stamping is a cost-effective manufacturing process, as it requires minimal tooling and equipment, making it a great choice for small to medium-sized production runs.

In conclusion, sheet metal stamping is a versatile and efficient manufacturing process that is used in a variety of industries to produce high-quality parts quickly and cost-effectively. Its ability to produce a wide range of shapes and forms makes it an essential tool in modern manufacturing, and its continued use is crucial for the advancement of technology and industry.

Understanding the Sheet Metal Stamping Process

Sheet metal stamping is a manufacturing process that involves shaping metal sheets into the desired form and size using specialized machines and tools. This process is widely used in various industries, including automotive, aerospace, electronics, and construction.

The sheet metal stamping process requires a combination of skills and equipment to produce high-quality products. It involves several stages, including designing, prototyping, tooling, and production.

The first step in the sheet metal stamping process is designing the product. This involves creating a 3D model of the product using computer-aided design (CAD) software. The design should consider various factors, such as the material type, thickness, and tolerances.

Once the design is finalized, the next step is prototyping. This involves creating a physical model of the product using a 3D printing r or other prototyping techniques. The prototype helps to test the product’s functionality and identify any design flaws that need to be addressed.

After the prototype is approved, the next step is tooling. This involves creating specialized tools and equipment to shape the metal sheets into the desired form. The tooling process can be expensive, but it is essential to ensure the quality and accuracy of the final product.

Once the tooling is completed, the production phase can begin. This involves feeding the metal sheets into the stamping machine and using the specialized tools to shape them into the desired form. The stamping machines can work at high speeds and produce large quantities of products in a short amount of time.

The sheet metal stamping process offers several advantages, including high accuracy, repeatability, and cost-effectiveness. It also allows for a wide range of shapes and sizes to be produced, making it suitable for various applications.

In conclusion, the sheet metal stamping process is a crucial manufacturing process that involves shaping metal sheets into the desired form and size. It requires a combination of skills and equipment to produce high-quality products. By understanding the sheet metal stamping process, manufacturers can create cost-effective, accurate, and repeatable products for a wide range of applications.

Advantages of Sheet Metal Stamping

Sheet metal stamping is a process that involves shaping metal sheets into various forms using a stamping machine. This process is widely used in the manufacturing industry due to its numerous advantages. Here are some of the benefits of sheet metal stamping:

- High Precision

Sheet metal stamping is a highly precise process that produces parts with consistent accuracy. The stamping process allows for tight tolerances, which means that parts can be made to exact specifications. This precision ensures that parts fit together perfectly, which reduces the need for additional finishing work.

- Cost-Effective

Sheet metal stamping is a cost-effective process because it uses raw materials efficiently, with minimal waste. The stamping process also allows for high-volume production, which reduces the per-unit cost of each part. This makes sheet metal stamping an ideal process for mass production of metal parts.

- Versatility

Sheet metal stamping can be used to produce a wide variety of shapes and sizes. The stamping process can be customized to create parts with different features, such as holes, slots, and flanges. This versatility makes sheet metal stamping an ideal process for producing complex metal parts.

- Strength and Durability

Sheet metal stamping produces parts that are strong and durable. The stamping process compresses the metal, which makes it stronger and more resistant to bending and cracking. This strength and durability make sheet metal stamping an ideal process for producing parts that need to withstand high stress and heavy loads.

- Speed

Sheet metal stamping is a fast process that can produce parts quickly and efficiently. The stamping machine can produce multiple parts at once, which reduces the time needed to produce each part. This speed makes sheet metal stamping an ideal process for producing parts that have a short lead time.

In conclusion, sheet metal stamping is a highly precise, cost-effective, versatile, strong, durable, and fast process for producing metal parts. These advantages make sheet metal stamping an ideal process for the manufacturing industry.

Types of Sheet Metal Stamping

Sheet metal stamping is a process that uses a hydraulic or mechanical press to form sheet metal into various shapes. There are several types of sheet metal stamping techniques used in manufacturing. The following are some common types of sheet metal stamping:

- Blank and Pierce Stamping: This technique is used to create holes or openings in the sheet metal. The punch is used to create the hole while the die is used to hold the sheet metal in place.

- Bending: This process involves using a punch and die to create a bend in the sheet metal. The angle of the bend can be controlled by adjusting the punch and die.

- Coining: This technique is used to create a raised design or text on the sheet metal. The metal is compressed between the punch and die, creating a raised design.

- Embossing: This process involves creating a raised design on the sheet metal by using a punch and die.

- Flanging: This technique is used to create a flange on the sheet metal. The punch and die are used to create a bend in the sheet metal, which is then formed into a flange.

- Stretching: This process involves stretching the sheet metal to create a specific shape. The metal is held in place by the die while the punch stretches the metal.

Sheet metal stamping is a versatile process that can be used to create a wide range of shapes and designs. The type of stamping technique used will depend on the desired outcome and the properties of the sheet metal being used.

Metal Stamping Design Processes

Metal stamping is a manufacturing process that is used to convert flat metal sheets into specific shapes. The process can be used to create a wide range of products and is commonly used in the automotive and aerospace industries. Here are some of the essential design processes involved in metal stamping:

Designing the Part

The first step in metal stamping is to design the part that will be stamped. This involves creating a detailed drawing of the part, including all the necessary dimensions and specifications. One of the essential considerations when designing a stamped part is the material that will be used. The material chosen will have a significant impact on the stamping process, so it is essential to choose the right material for the job.

Material Selection

The next step is to select the material that will be used to make the part. This is an essential consideration, as different materials have different properties and characteristics that can impact the stamping process. Some of the most commonly used materials for metal stamping include aluminum, brass, copper, stainless steel, and carbon steel.

Tooling Design

Once the part and material have been selected, the next step is to design the tooling that will be used to stamp the part. Tooling refers to the dies and punches that are used to cut and shape the metal sheets. Tooling design is a critical part of the metal stamping process, as it determines the accuracy and precision of the final product.

Prototype Development

Before beginning mass production, it is essential to develop a prototype of the stamped part. This allows designers and engineers to test the part’s functionality and make any necessary modifications before mass production begins. Prototyping is a critical step in the design process, as it can save time and money by identifying potential issues before they become major problems.

Mass Production

Once the prototype has been tested and approved, mass production can begin. The metal sheets are loaded into the stamping machine, and the tooling is used to cut and shape the sheets into the desired shape. The stamped parts are then inspected for quality and sent off for finishing processes, such as painting or plating.

Metal stamping is a complex process that requires careful planning and execution. By following these essential design processes, manufacturers can create high-quality stamped parts that meet the necessary specifications and requirements.

Meet Your Metal Stamping Needs

Are you tired of using the same old boring metal pieces for your projects? Do you want to spice things up and add some flair to your creations? Look no further than sheet metal stamping!

Sheet metal stamping service is the process of creating metal parts by stamping them out of a sheet of metal. It’s a great way to create unique and intricate shapes that are perfect for any project. Plus, it’s a cost-effective way to create large quantities of parts quickly and easily.

Here at [Longsheng Technology], we specialize in sheet metal stamping. Our expert team is dedicated to providing you with high-quality metal parts that are tailored to your specific needs. We use the latest technology and equipment to ensure that your parts are precise and accurate every time.

But don’t just take our word for it – our customers love our metal stamping services! Here are just a few reasons why:

- We offer a wide range of materials to choose from, including stainless steel, aluminum, brass, and more.

- Our turnaround times are fast, so you can get your parts when you need them.

- We offer competitive pricing, so you don’t have to break the bank to get the metal parts you need.

- Our team is friendly and knowledgeable, so you can trust that you’re getting the best service possible.

So what are you waiting for? Whether you need metal parts for a DIY project or for your business, sheet metal stamping is the way to go. Contact us today to learn more about our metal stamping services and to get started on your next project!