Metalworking is an essential process that involves shaping, forming, and assembling metal parts. Two of the most common techniques used in metalworking are stamping and forming. At first glance, these two methods may appear to be interchangeable, but they differ significantly in terms of their applications, tools, and outcomes. In this blog post, we will explore the difference between stamping and forming metal, as well as their unique features, benefits, and drawbacks. Join us in this exciting journey to discover the fascinating world of metalworking.

What is Stamping Metal?

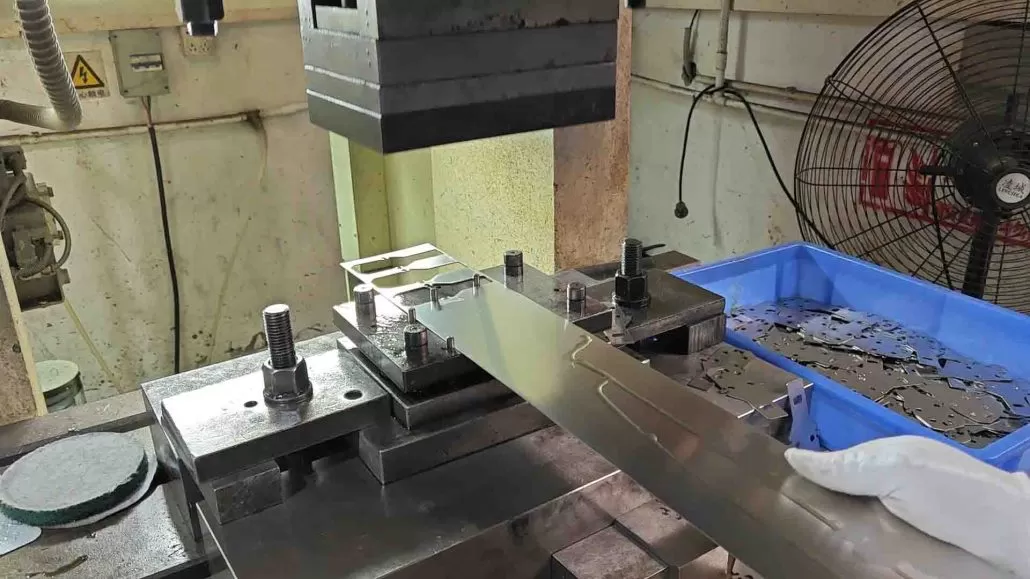

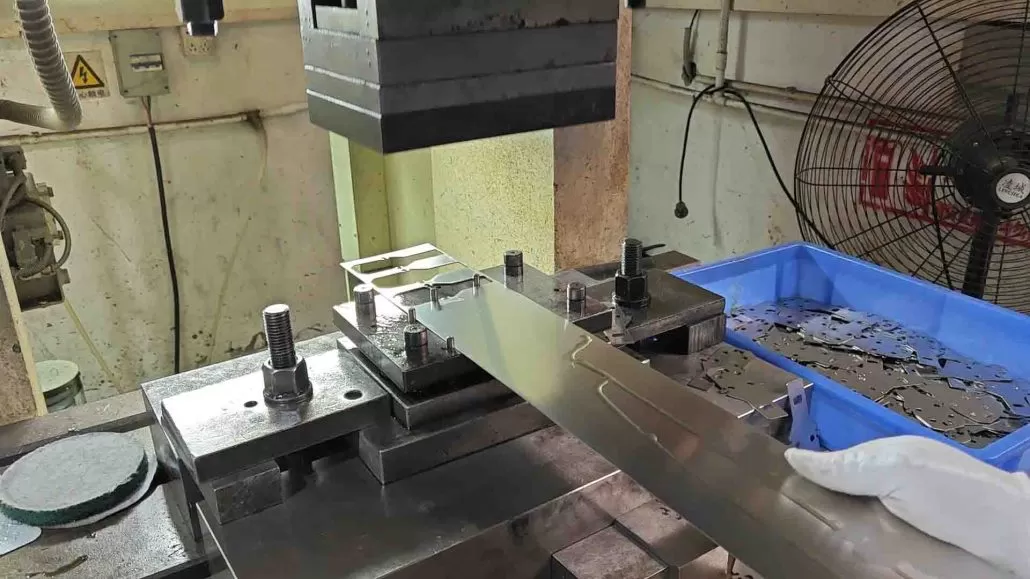

Stamping is the process of applying pressure to a piece of sheet metal to produce a desired shape or pattern using a press machine. This technique uses a die, which acts as a mold to cut, bend, or shape the metal. Stamping is widely used in the automotive, aerospace, and electronics industries to create precise and intricate parts such as brackets, frames, and enclosures. Its advantages include high accuracy, repeatability, and speed, but it may also cause material waste, tool wear, and burr formation.

How Does Stamping Differ from Forming Metal?

Metalworking is a process that involves various techniques, including stamping and forming. Although these two terms are often used interchangeably, they are quite different. Here is an overview of the differences between stamping and forming:

Stamping Metal

Stamping is a metalworking process that involves creating shapes and designs on metal sheets using a stamping press. A stamping press is a machine that uses a die and a punch to shape metal. The die is the tool that creates the shape or design, while the punch applies pressure to the metal, forcing it into the die. Stamping is commonly used to create parts for machines, appliances, and vehicles.

Forming Metal

Forming, on the other hand, is a metalworking process that involves shaping metal without cutting or removing material. This process involves bending, stretching, and shaping metal sheets using various techniques such as rolling, hammering, and pressing. Forming is commonly used to create curved or rounded parts for machines, appliances, and vehicles.

In conclusion,While stamping uses a die to cut metal, forming employs a series of tools to reshape it gradually. Forming is a broader term that encompasses several sub-techniques such as bending, folding, rolling, and forging. Unlike stamping, which is more suitable for short production runs, forming can be used for both large and small quantities. Forming also offers greater flexibility, efficiency, and cost-effectiveness, but it requires more skill, experience, and time than stamping.

What Are Some Common Types of Forming Metal?

Metal forming is the process of shaping metal into different forms and sizes. There are various ways to form metal, and each method produces a unique result. Here are some common types of metal forming:

- Casting: This is a process that involves pouring molten metal into a mold. Once the metal has cooled and solidified, the mold is removed, leaving behind the desired shape.

- Forging: Forging is the process of shaping metal by hammering, pressing, or rolling it into the desired shape. This is a highly effective way of creating strong, durable metal parts.

- Extrusion: Extrusion is the process of forcing metal through a die to create a specific shape. This method is commonly used to create pipes, tubing, and other long, hollow shapes.

- Stamping: Stamping is the process of using a stamping press to cut or form metal into a specific shape. This method is commonly used to create automotive parts, appliances, and other metal products.

- Spinning: Spinning is the process of shaping a flat piece of metal into a curved shape using a lathe. This method is commonly used to create metal bowls, vases, and other decorative items.

These are just a few of the many types of metal forming techniques. Each method has its own advantages and disadvantages, and the right choice will depend on the specific needs of the project.

In conclusion,The most common types of forming metal are bending and rolling. Bending involves the use of a press brake or a folding machine to bend the metal at a specific angle. This technique is widely used in the construction, architecture, and furniture industries to create panels, frames, and supports. Rolling, on the other hand, uses a series of rollers to reduce the thickness and shape the metal. This technique is used in the manufacturing of pipes, tubes, and cylinders.

How Do Stamping and Forming Affect Material Properties?

When it comes to manufacturing metal parts, stamping and forming are two popular methods used to shape and manipulate the raw material. While both techniques are effective at creating complex shapes and designs, they can also have an impact on the properties of the material being used.

Stamping involves pressing a metal blank into a die to create a specific shape. This process can result in changes to the grain structure of the metal, which can affect its strength and ductility. Additionally, stamping can cause the material to become work-hardened, meaning it becomes stronger but also more brittle.

Forming, on the other hand, involves bending or shaping a metal sheet without cutting or removing any material. This process can also affect the material’s properties, particularly when it comes to the formation of cracks and defects in the metal. However, forming typically results in less work hardening than stamping, which can make the material more ductile.

Overall, Both stamping and forming can have a significant impact on the physical and mechanical properties of metal. Stamping may cause deformation, strain hardening, and cracking, while forming may induce residual stresses, anisotropy, and elongation. To mitigate these effects, metalworkers often use annealing, tempering, and heat treating methods to restore the metal’s original properties. They may also use computer-aided simulation and modeling to optimize the stamping and forming processes and minimize defects.

What Are the Advantages and Drawbacks of Stamping and Forming?

When it comes to stamping forming services, there are different processes that can be used to shape and mold materials into finished products. Two common processes are stamping and forming, each with its own unique advantages and drawbacks.

Advantages of Stamping

Stamping is a manufacturing process that involves cutting and shaping materials using a press and a die. Here are some of the advantages of stamping:

- High Precision: Stamping allows for the production of highly precise parts with consistent quality. This is because the process uses a die that is designed to create a specific shape, which ensures that each part is identical.

- High Speed: Stamping is a fast process that can produce a large number of parts quickly and efficiently. This makes it ideal for high-volume production runs where time is of the essence.

- Low Cost: Stamping is a cost-effective manufacturing process, especially for high-volume production runs. The process is highly automated, which means that labor costs are kept to a minimum.

- Versatile: Stamping can be used to produce a wide range of products, from simple parts to complex assemblies. This makes it a popular choice for manufacturers in many different industries.

Drawbacks of Stamping

Despite its advantages, stamping also has some drawbacks, including:

- Limited Material Choice: Stamping is best suited for materials that are easy to shape and cut, such as metals and plastics. It is less effective on harder or more brittle materials such as ceramics or glass.

- High Tooling Costs: Stamping requires expensive tooling, which can be a significant upfront cost for manufacturers. This can make it difficult for small manufacturers or those with limited budgets to adopt the process.

- Design Limitations: Stamping is limited by the design of the die, which can make it difficult or impossible to produce certain shapes or features. This means that stamping may not be the best choice for products that require a lot of customization or unique features.

Advantages of Forming

Forming is a manufacturing process that involves shaping materials using heat and pressure. Here are some of the advantages of forming:

- Versatility: Forming can be used to shape a wide range of materials, including metals, plastics, and ceramics. This makes it a popular choice for manufacturers who work with a variety of materials.

- Complex Shapes: Forming can produce complex shapes and designs that would be difficult or impossible to achieve with stamping. This is because the process allows for more flexibility and customization.

- Minimal Material Waste: Forming can be a more efficient manufacturing process than stamping, as it produces less material waste. This makes it a more environmentally friendly choice.

Drawbacks of Forming

Despite its advantages, forming also has some drawbacks, including:

- High Cost: Forming can be a more expensive manufacturing process than stamping, especially for low-volume production runs. This is because the process requires more specialized equipment and skilled labor.

- Longer Lead Times: Forming can take longer than stamping to produce parts, as it involves heating and cooling processes. This can make it difficult for manufacturers who need parts quickly.

- Limited Precision: Forming may not be as precise as stamping, as it is more difficult to control the shape and size of the finished product. This can be a disadvantage for manufacturers who require highly precise parts.

both stamping and forming have their own unique advantages and drawbacks. Stamping and forming have distinct advantages and drawbacks depending on the task, material, and production volume. Stamping is faster, more accurate, and more automated than forming, but it may not be suitable for complex shapes, thick materials, or low volumes. Forming, on the other hand, offers greater flexibility, customization, and scalability, but it may require multiple tools, longer lead times, and higher costs than stamping.

In conclusion, stamping and forming metal are two essential processes that metalworkers use to shape and transform sheet metal into various products. While stamping uses a die to cut and shape metal, forming employs a series of tools to reshape it gradually. Both methods have their unique features, benefits, and drawbacks, and choosing the right one depends on several factors such as the material, the desired shape, and the production volume. By understanding the difference between stamping and forming, you can make better-informed decisions about your metalworking projects and achieve superior results.

FAQ

Metal stamping and forming are used in a wide range of industries, including automotive, aerospace, electronics, and construction. These processes are particularly useful for producing parts and components that require high strength and durability.

Most metals can be stamped, including aluminum, brass, copper, steel, and stainless steel. The type of metal used will depend on the specific application and desired end result.