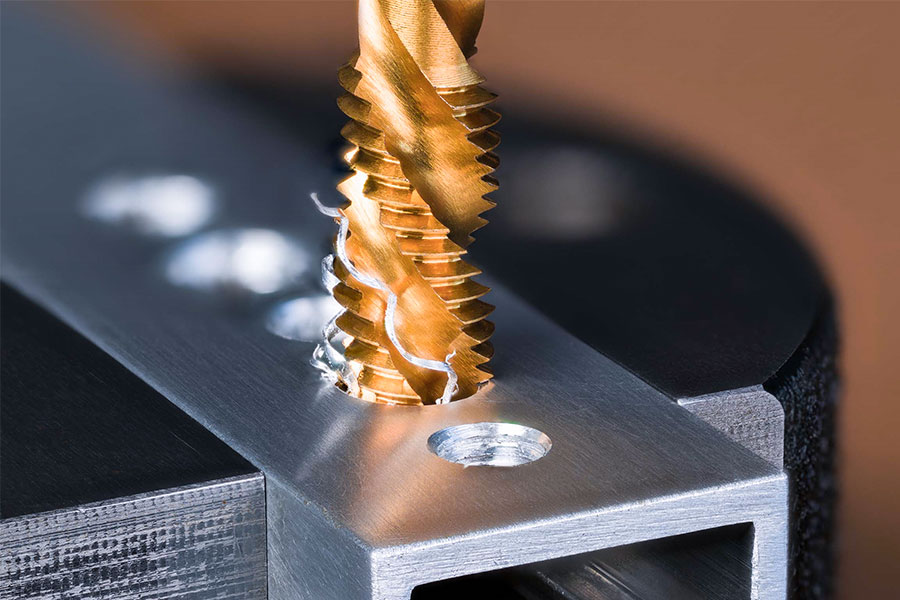

What Are Taps In Machining?

Taps are the essential tools for creating reliable threaded connections in machining and are much more complex than their everyday names suggest. The correct choice of tap type, base material, and coating is key to ensuring part quality, maximizing production efficiency, and controlling costs. Ignoring these factors can lead to thread defects, tool wear, and scrapped parts.