How to Avoid Weld Lines in Injection Molding

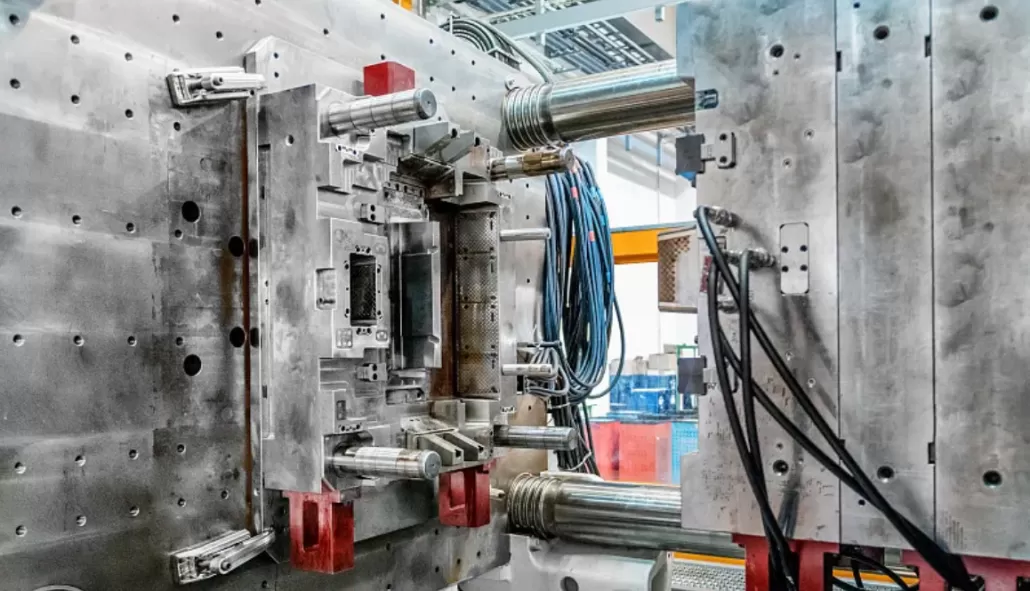

Injection molding is a popular manufacturing process used to create complex parts for a variety of industries. From automotive to medical and aerospace, injection molding has become an indispensable tool for producing high-quality parts in large quantities. However, one common problem that manufacturers face during plastic injection molding is weld lines. In this informative article, we will be discussing how to avoid weld lines in injection molding.