Is Injection Molding Cost Efficient? Here’s What You Need to Know

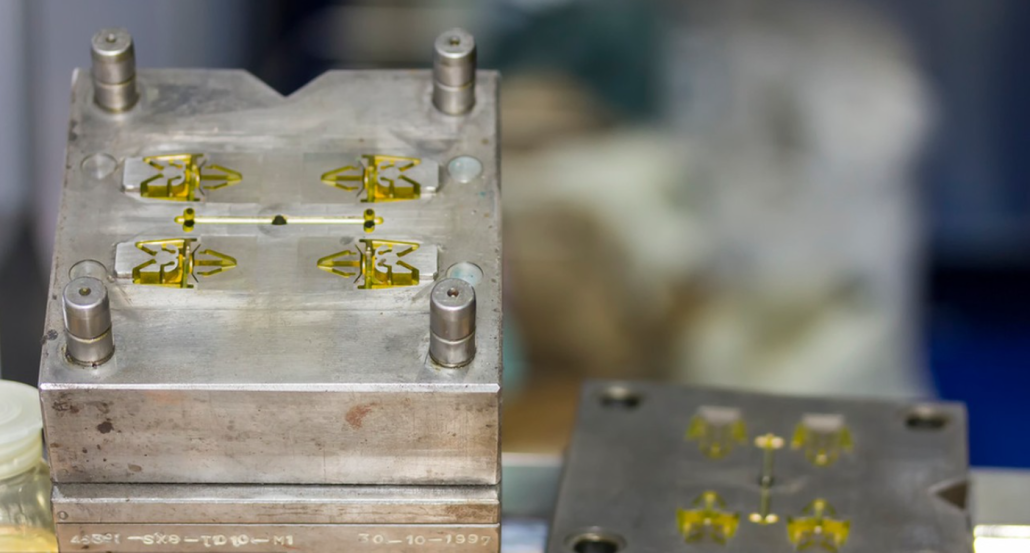

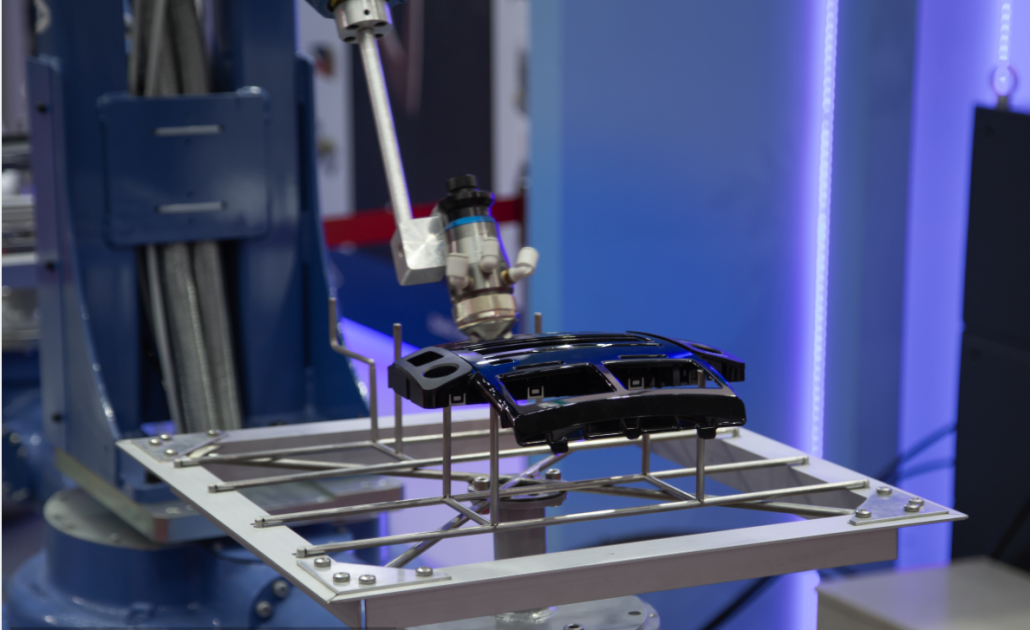

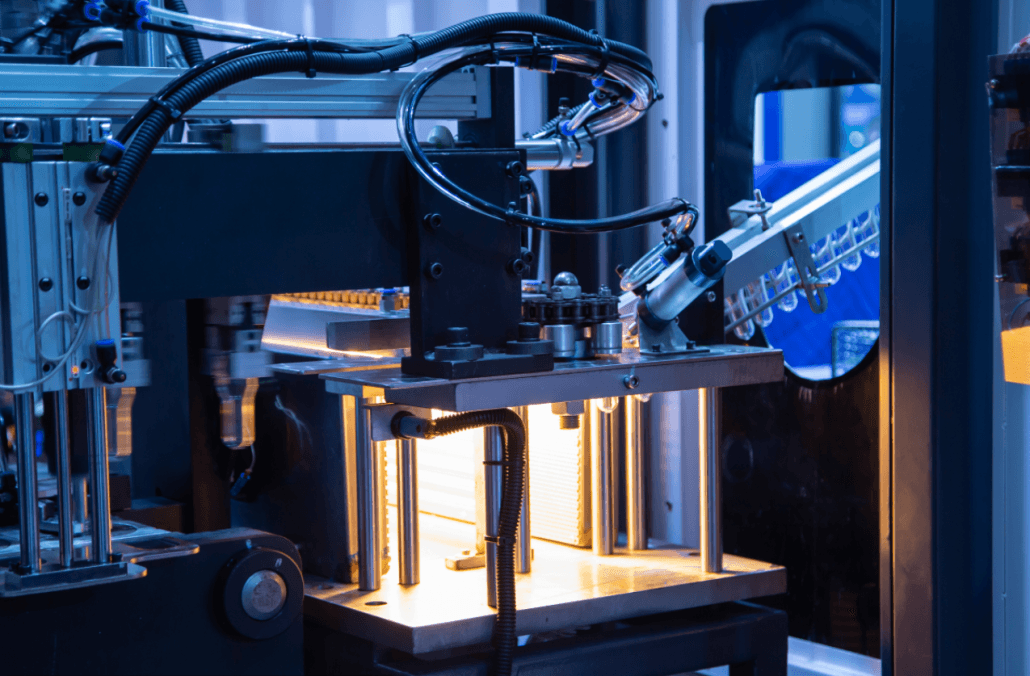

Injection molding is an incredibly cost-efficient manufacturing process used to produce everything from car parts to toys. It is widely used in various industries for its ability to produce high-quality, consistent parts at a low cost. But how cost-efficient is injection molding, really? In this article, we’ll explore the key drivers of injection molding costs and explain why this Injection molding process is one of the most cost-effective options available.

Is Injection Molding Cost Efficient? Here’s What You Need to Know Read More »