CNC machining has completely transformed the manufacturing industry, making production more precise, efficient, and cost-effective. But with so many types of CNC machining to choose from, it’s difficult to know which one is suitable for your project. In this article, we will explore the five most common types of precision CNC machining and their unique advantages.

1) 5-Axis Machining

5-axis machining is widely considered the most advanced form of CNC milling. It allows for complex geometries and shapes to be created with unparalleled precision. This type of machining is particularly useful for industries like aerospace and medical devices, where intricate designs are essential.

At Longsheng, we specialize in 5-axis machining and have a team of experienced professionals who are experts in the field. We use the latest technology and equipment to ensure that our clients receive the highest quality products.

2) Swiss Machining

Swiss machining is a type of CNC turning that is particularly useful for small and complex parts. This type of mechanical processing is commonly used in the production of medical equipment and electronic products. One of the main advantages of Swiss machining is its ability to quickly and accurately produce a large number of parts.

At Longsheng, our Swiss machining services are known for their precision and reliability. Our team of professionals has years of experience in this field and we use only the best equipment and materials to produce the highest quality products.

3) Wire EDM Machining

Wire EDM (Electrical Discharge Machining) is a type of CNC machining that uses an electrically charged wire to cut intricate shapes. This type of machining is often used in the production of metal parts and molds.

At Longsheng, we offer wire EDM machining services that are second to none. We use the latest technology and equipment to ensure that our clients receive the most accurate and high-quality products. Our team of professionals is highly skilled and experienced, ensuring that every project is completed to the highest standards.

4) Waterjet Machining

Waterjet machining is a type of CNC milling that uses a high-pressure jet of water to cut through materials. This type of machining is particularly useful for cutting through thick materials like metal and stone.

At Longsheng, we offer waterjet machining services that are both precise and efficient. Our team of professionals is highly skilled and experienced in this type of machining, ensuring that every project is completed to the highest standards.

5) Laser Cutting

Laser cutting is a type of CNC machining that uses a high-powered laser to cut through materials. This type of machining is particularly useful for intricate designs and shapes.

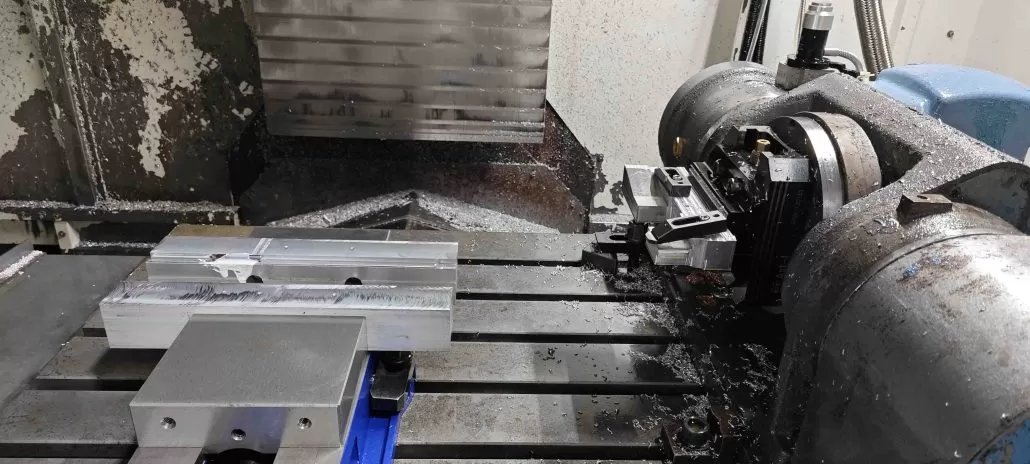

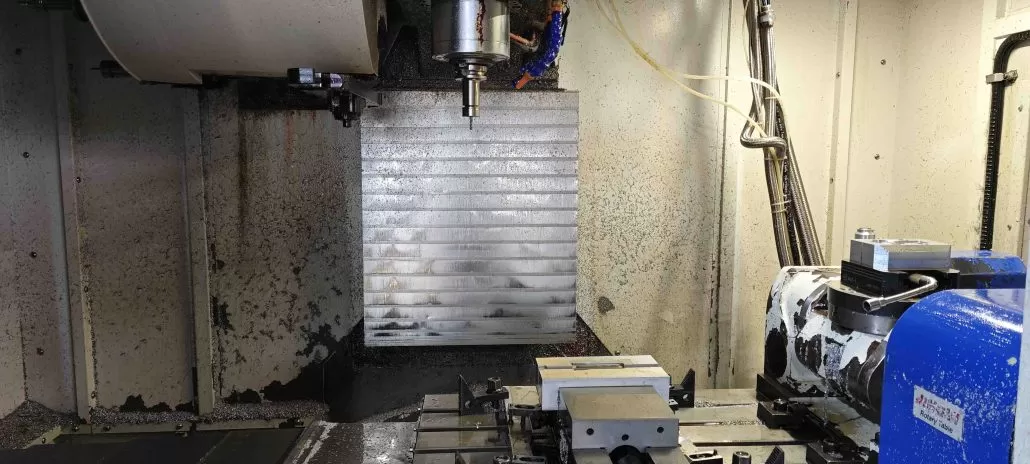

6)Milling

The milling process involves cutting and shaping metal workpieces using a rotating cutting tool. The tool moves along multiple axes to remove material from the workpiece surface, creating the desired shape or feature. Milling machines are highly versatile and can work on materials such as steel, aluminum, copper, and plastics.

7)Turning

The turning process is similar to milling, but it focuses on cylindrical workpieces, such as shafts, rods, and bolts. The material is rotated while a cutting tool is applied, making it possible to create features such as threads, grooves, and chamfers.

At Longsheng, we offer laser cutting services that are both accurate and efficient. Our team of professionals uses the latest technology and equipment to ensure that every project is completed to the highest standards.

In summary, CNC machining has a series of advantages in terms of accuracy, efficiency, and cost-effectiveness. The above five types of mechanical processing are commonly used in industry, each with its own unique advantages.

At Longsheng, we provide a series of CNC machining services tailored to meet customer needs. Contact us immediately to learn more about how we can help you meet your precision CNC machining needs.

I have been examinating out many of your stories and i can state clever stuff. I will surely bookmark your site.

Thank you for your attention, please subscribe to us and share valuable information with your friends in need, have any needs, please send us an inquiry.

Hey very cool website!! Man .. Excellent .. Wonderful .. I will bookmark your web site and take the feeds also…I am happy to find numerous useful info here within the submit, we want develop extra strategies in this regard, thank you for sharing.