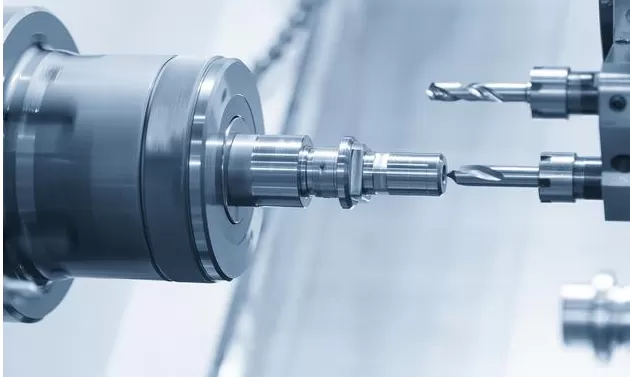

CNC machining has become an increasingly popular manufacturing process for creating high-quality parts with precision. It is also an excellent option for producing parts used in energy applications due to the unique benefits it offers. In this article, we’ll explore the advantages of using CNC machining parts for energy applications.

Precision

One of the key advantages of CNC machining is its ability to produce parts with high precision. This is especially important in energy applications where even the slightest deviation from the intended specifications can impact performance. CNC machines are capable of producing parts with tight tolerances, ensuring that they meet the exact specifications required for energy applications.

Consistency

Another advantage of CNC machining is its ability to produce consistent parts. This is important for energy applications where multiple parts must work together seamlessly to achieve optimal performance. CNC machines can produce identical parts with high consistency, which reduces the risk of errors and improves overall performance.

Durability

Energy applications often require parts that are durable and can withstand harsh environments. CNC machining can produce parts from a wide variety of materials, including metals and plastics, that are well-suited for these applications. CNC machines can also create parts with complex shapes and intricate designs, which can improve their durability and performance.

Cost-Effective

CNC machining can be a cost-effective option for producing parts used in energy applications. While the initial investment in CNC equipment can be significant, the ability to produce consistent, high-quality parts can ultimately reduce costs over the long term. CNC machines can also produce parts quickly, which can further reduce costs and lead times.

Conclusion

In conclusion, CNC machining offers a range of benefits for producing parts used in energy applications. Its ability to produce precise, consistent, and durable parts makes it an excellent choice for these applications. Additionally, its cost-effectiveness and quick turnaround times make it an attractive option for manufacturers. By utilizing CNC machining for energy applications, manufacturers can achieve high-quality parts that meet exact specifications and perform reliably over the long term.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC Milling Parts Machining Service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items.