Founded in 2019 by Mr. Nick Zhang, LS Technology is a professional manufacturer of CNC parts, sheet metal, stamping parts and injection molds. In the blink of an eye, Longsheng has gone through five years. Through continuous practice and learning, Longsheng’s partners have worked hard and sown tenaciously in this new era of rapid development, and have stood at the forefront of many competitors in the field of hardware molds, standing proudly among the others! In order to thank our customers for their continued support and love , we have specially planned a grand 30% off carnival, so that you can feel our full sincerity while producing technical accessories.

Five years of glory, witness to quality

Since the establishment of the company, we have always adhered to the tenet of “quality first, customer first” and constantly pursued excellent quality. Our hardware mold products are widely used in various industries. With exquisite craftsmanship, stable performance and high-quality service, we have won the trust and praise of our customers. In these five years, we have witnessed the ups and downs of the industry, as well as the growth and expansion of the company itself. Today, we have become a leader in the hardware mold industry, providing high-quality products and services to countless customers.

Anniversary celebration, gratitude and feedback

To celebrate this important moment, we are launching a limited-time anniversary feast with 30% off! During the event, all those who choose Longsheng for customized parts will enjoy a 30% discount, allowing you to get your favorite parts at a more favorable price. In addition, we have also prepared additional services. Longsheng will provide free quotations for your design drawings to help you save costs as much as possible, making your project economically feasible and making your design drawings a reality. Parts are not a dream.

Understand Longsheng, choose Longsheng

Dongguan Longsheng Hardware Technology Co., Ltd. is a professional hardware and plastic parts manufacturing enterprise founded by Mr. Zhang and several professional engineers. Mr. Zhang is an expert in rapid prototyping and CNC machining. He majored in CNC plus in college and became a professional engineer and an excellent manager after graduation. He was the operations director of several large factories and managed the company’s production, technology and quality departments for more than 10 years. Now operating a number of factories, including sheet metal processing, CNC machining and injection molding, we provide customers with professional processing suggestions and manufacture hardware parts that meet customer requirements. We are not only suppliers to many large foreign factories in China, but also provide professional and effective services and suggestions to overseas customers.

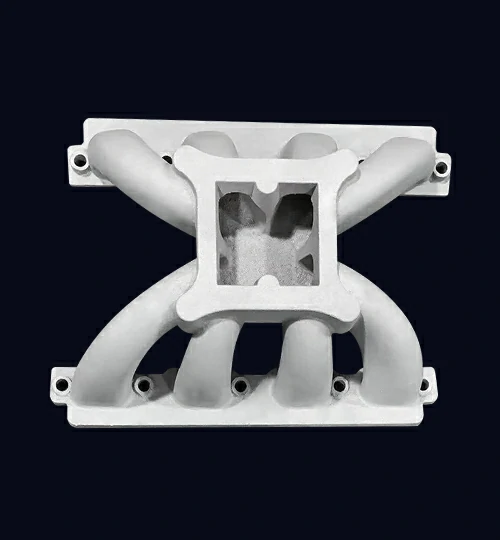

Since its establishment, our company has focused on the professional production of technical accessories. We are mainly engaged in various household appliance appearance, auto parts, medical device accessories and internal structure model production/rapid prototyping/aluminum and aluminum alloy parts/small batch and mass production to provide customers with a full range of services from hand-made prototypes to mass production. . The main production equipment includes CNC machining centers, and auxiliary equipment includes lathes, milling machines, sandblasting machines, engraving machines, etc.

We are experts in making your product a perfect finish. In addition to professional advice and production, we also provide all surface treatments to enhance the aesthetic appearance of your products. Surface treatments include smooth, polished, spray-painted, sandblasted, anodized, electroplated, silk screen, and laser etching. Products can be plated with zinc, chromium, nickel, aluminum and other metals. There are many other services available and you can create any product you want.

Diverse services to keep you worry-free

1.CNC machining services

Accurate, reliable and efficient! We specialize in providing our customers with superior precision CNC machining services. Whether milling or turning, with ISO 9001 certified production processes combined with expert machining experience and advanced CNC machining tools, we can ensure your online CNC parts are made correctly and delivered on time every time. CNC machining is ideal for rapid prototyping and on-demand production.

Since it is a highly computerized and versatile manufacturing process, the following are the CNC services we offer. Whether you need CNC prototype production or mass production, Longsheng CNC Parts Online provides you with a variety of options.

1.1Longsheng CNC machining capabilities

Our precision CNC machining services not only cover the CNC machining of individual workpiece, but also cover the entire production cycle, including design, model making, prototyping and mass production. And it can ensure that the CNC parts size is within an acceptable range and effectively fits with other CNC parts.

| Abilities | CNC Milling | CNC Turning | |

|---|---|---|---|

| Maximum Part Size | 1300mm × 800 mm × 300mm 51.2in. × 31.5in. × 11.8in. | 300mm × 500mm 11.8in. × 19.7in. | |

| Minimum Part Size | 1mm × 1mm 0.04in. × 0.04in. | 1mm × 1mm 0.04in. × 0.04in. | |

| Minimum Feature Size | +/- 0.3mm +/- 0.011in. | +/- 0.3mm +/- 0.011in. | |

| Standard Tolerances | +/- 0.005mm +/- 0.0002in. | +/- 0.005mm +/- 0.0002in. | |

| Radii | Sharp inside corners on a CNC parts will be radiused (rounded) as a natural result of the precision CNC machining process. | ||

| Linear Dimension | +/- 0.005mm +/- 0.0002in. | +/- 0.005mm +/- 0.0002in. | |

| Hole Diameters (Not Reamed) | +/- 0.005mm +/- 0.0002in. | +/- 0.005mm +/- 0.0002in. | |

| Shaft Diameters | +/- 0.005mm +/- 0.0002in. | +/- 0.005mm +/- 0.0002in. | |

| Edge Condition | *Sharp corner will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radii, must be indicated on the drawing. | ||

| Threads and Tapped Holes | Diameter: Φ 1.5-5 mm, depth: 3×diameter Diameter: Φ 5 mm or more, depth: 4-6×diameter | ||

| Laser Etching | Minimum width of 0.5 mm, depth of 0.1 mm | use laser marking to create standard text for CNC turned parts | |

| *longsheng can produce threads of any specification and size required by our customers. | |||

| Lead Time | 3 Business Days | ||

| Maximum CNC parts size varies by material.Contact our team if you need further information.Click here to email us | |||

1.2Why Choose Longsheng Customized CNC Machining Services?

By choosing our precision CNC machining manufacturer, you will receive high-quality, customized parts, fast delivery, and competitive prices. We will cooperate with you to provide excellent CNC machining solutions for your project.

- Multi Material Machining:We have the ability to handle multiple materials, and we can provide professional solutions no matter what material of cnc parts you need to process.

- Customized Services:Provide customized solutions based on customer design requirements and specifications to ensure that CNC parts meet their unique needs.

- Competitive Pricing:We provide competitive prices and cost-effective solutions to ensure that customers gain the greatest advantage in cost control.

- Rapid Delivery:We have efficient production processes and flexible production plans, which enable us to timely deliver customer orders and meet urgent project needs.

1.3 Advantages Of CNC Machining

※ The CNC machining process offers a variety of benefits for prototyping and the production of custom CNC parts.

※ Complex CNC parts machined

※ Complex CNC parts machined

※ High volume, low cost

※ Multi-material selection

※ Tight tolerances(+/- 0.005mm)

※ High quality surface finishing

※ Quick-turn CNC parts within 3 day

2.Injection Molding Services

Want to turn your ideas into physical products? We are your trustworthy plastic injection molding service provider. Through our expertise and quality service, we will help you realize unique plastic products. Whether you need personalized customization or mass production, we can meet your needs. Our injection molding services help you save time and money on product development. Turnaround time for design feedback is only a few hours, and we provide free injection molding quotes.

2.1 Longsheng’s injection molding capabilities

Please check our injection molding parts manufacturing capabilities, For custom tolerances, mark them clearly on your drawing.

| Types | Size Tolerance |

|---|---|

| Maximum Part Size | 1000 × 800 × 300 mm 39.37 × 31.49 × 11.81 inch |

| Minimum Part Size | 1 × 1 × 1 mm 0.039 × 0.039 × 0.039 inch |

| Mold Cavity Tolerances | +/- 0.1 mm +/- 0.0039 inch |

| Part to Part Repeatability | +/- 0.15 mm or less +/- 0.0059 inch or less |

| Surface Finishing Options | Mirror polishing, electroplating, spraying, screen printing, etc |

| Available Mold Types | Steel and aluminum tooling |

| Production Grades Available | From 105 grade (prototype tools) to 101 grade (high production tools) |

| Tool Ownership | Customer-owned with mold maintenance |

| Lead Time | Starts at 3 business days, including fast quote responses with design-for-manufacturing (DFM) feedback |

2.2 Why Choose LongSheng For Custom Injection Molding Services?

- Rapid Quotation:Just upload the CAD file, you can quickly understand the manufacturing cost and keep abreast of the order status.

- Quick Molding:Longsheng has extensive experience in prototype manufacturing, ensuring that your components are completed with high quality in the later stages of the design and manufacturing process.

- Customized On Demand:Our auto parts manufacturing process is fully customizable according to your specifications, sizes, materials and surface requirements to ensure meeting your unique needs.

- Express Delivery:We are committed to providing, fast manufacturing and delivery to meet your production needs while providing you with greater flexibility to quickly respond quickly to market changes. Longsheng is a partner of your auto parts needs.

2.3Advantages Of Injection Molding

Injection molding is an efficient, precise and flexible manufacturing technology that produces plastic parts with great precision, speed and repeatability.

※ Complex geometries parts

※ Minimal material waste

※ Large selection of thermoplastic and thermoset materials

※ Precision and high tolerance

※ Cost-effective for large volumes

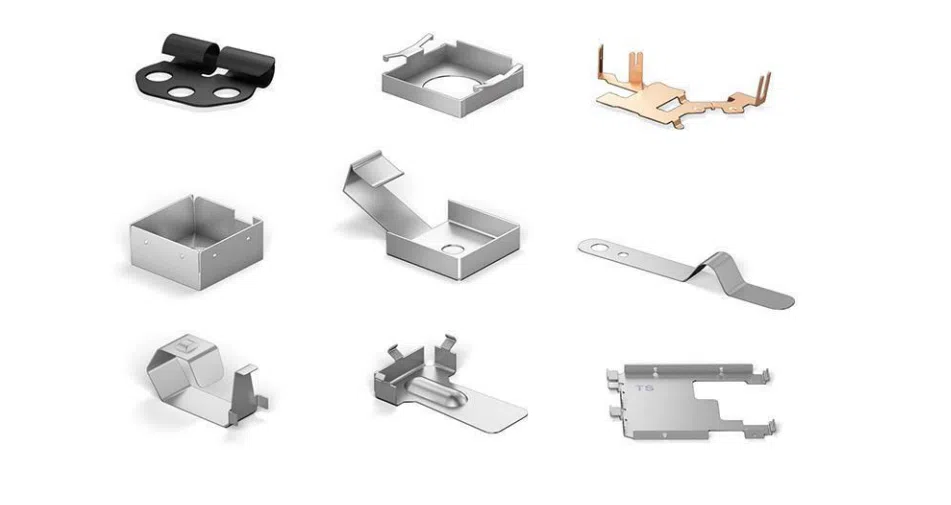

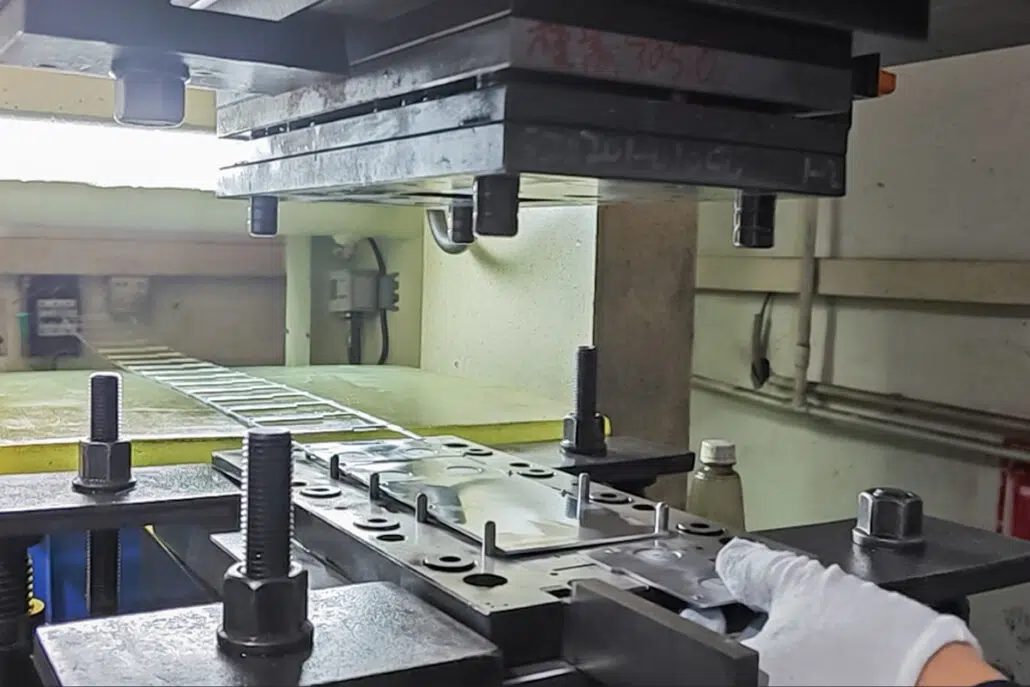

3.Sheet Metal Fabrication Services

For metal parts with uniform wall thickness, sheet metal fabrication is more cost-effective than CNC machining, and whether your project requires simple or complex cutting, stamping, bending or welding services, we can deliver. Can’t wait to complete your sheet metal project? No need to wait for a long period, we promise to provide you with customized sheet metal parts as soon as 3 days! From prototype design to efficient production, our efficient team will quickly respond to your needs, protect your project, and ensure that you occupy a leading position in the market!

3.1 Longsheng’s sheet metal Fabrication capabilities

By following the ISO 2768-m standard, your custom sheet metal fabrication service can more easily ensure the manufacturability and accuracy of parts, reducing errors and unnecessary manufacturing issues.

| Types | Tolerance |

|---|---|

| Bend edge straightness | +/- 0.2 mm +/- 0.008 inches |

| Edge to edge, single side | +/- 0.1 mm +/- 0.004 inches |

| Edge to hole, single side | +/- 0.1 mm +/- 0.004 inches |

| Hole to hole, single side | +/- 0.1 mm +/- 0.004 inches |

| Bend to edge/hole, single side | +/- 0.2 mm +/- 0.008 inches |

| Edge to feature, multiple sides | +/- 1.0 mm +/- 0.040 inches |

| Overformed parts, multiple sides | +/- 1.0 mm +/- 0.040 inches |

| Bend angle | +/- 1° |

| Weld joint location | +/- 0.2 mm +/- 0.008 inches |

| Surface finish thickness | +/- 0.05 mm +/- 0.002 inches |

3.2 Why Choose Longsheng’s Sheet Metal Fabrication Services?

- Quick Quotation:Just upload your design file and configure the materials, finishing options, and requirements. Our engineers analyze your part geometry and provide real-time and competitive pricing as well as comprehensive DFM feedback.

- Assured High Quality:We are a sheet metal fabrication factory certified by ISO 9001:2015 and can provide sheet metal component materials and full size inspection reports according to your requirements.

- Reliable Delivery:From prototype design to efficient production, we deliver high-quality sheet metal parts within our standard delivery time of 3 days.

- Readily Available Capacity:We have over 70 machines, and your sheet metal fabrication services can provide immediate and available production capacity.

3.3 Advantages of sheet metal Fabrication

Sheet metal fabrication includes a variety of techniques that offer many benefits. The final parts have uniform wall thickness with remarkable mechanical properties. The following are some of the major advantages of sheet metal fabrication.

※Accuracy And Efficiency

※Versatility

※High Capacity Production At Low Cost

※Manufacturing Of Lightweight Components

※Custom-Built Designs

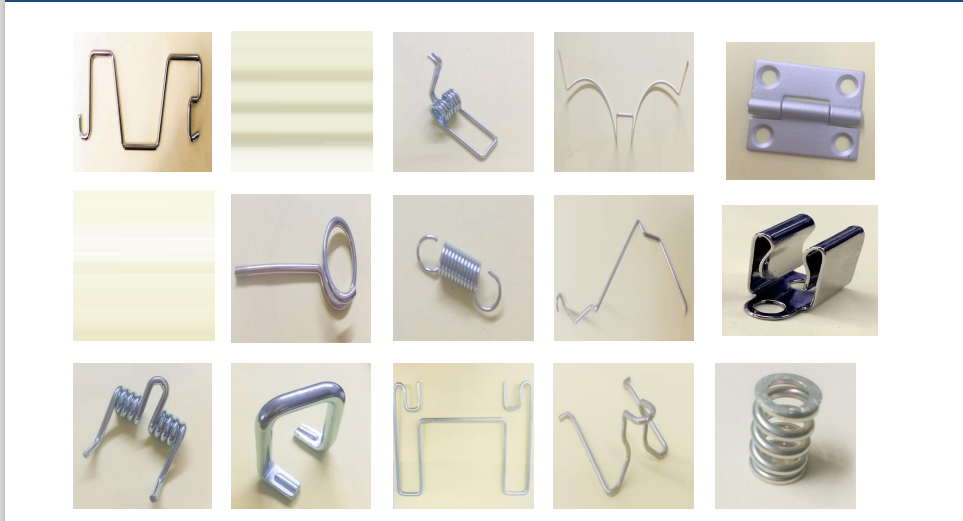

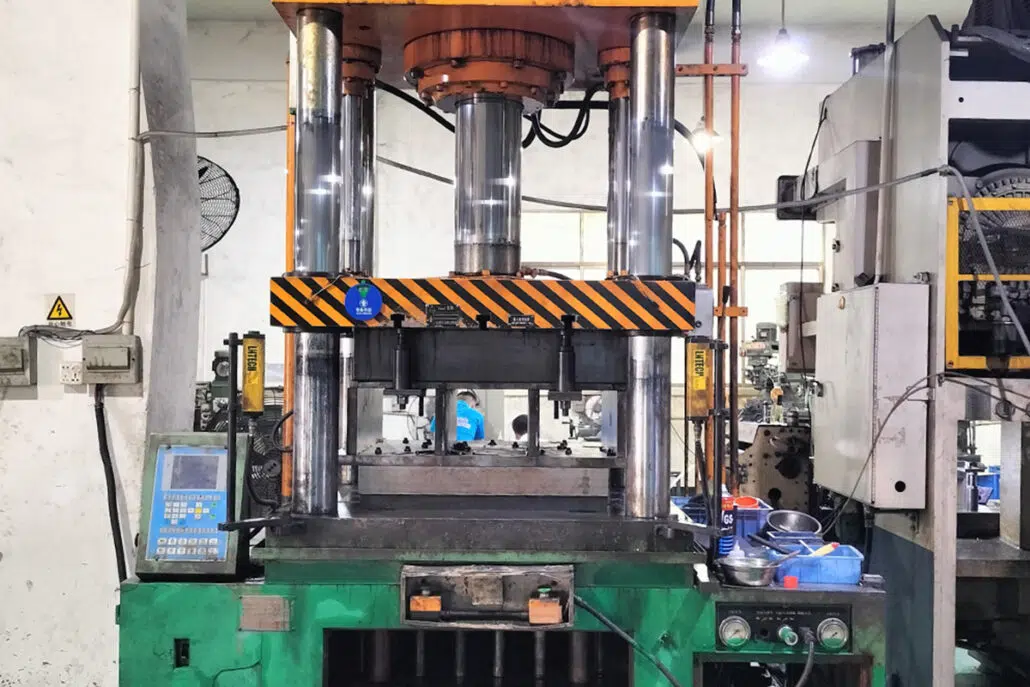

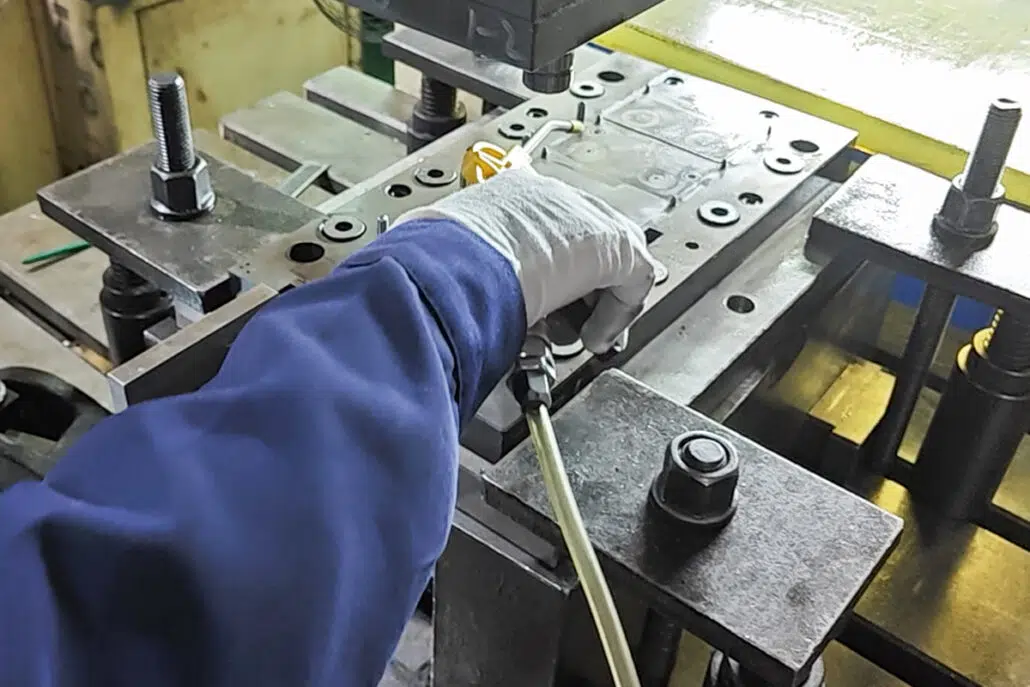

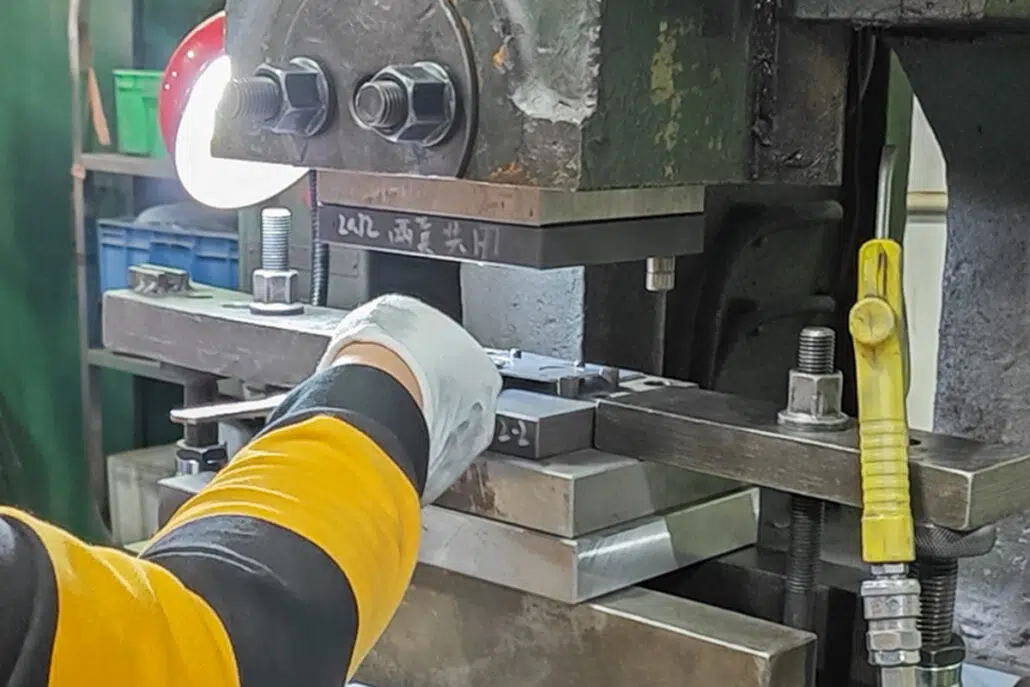

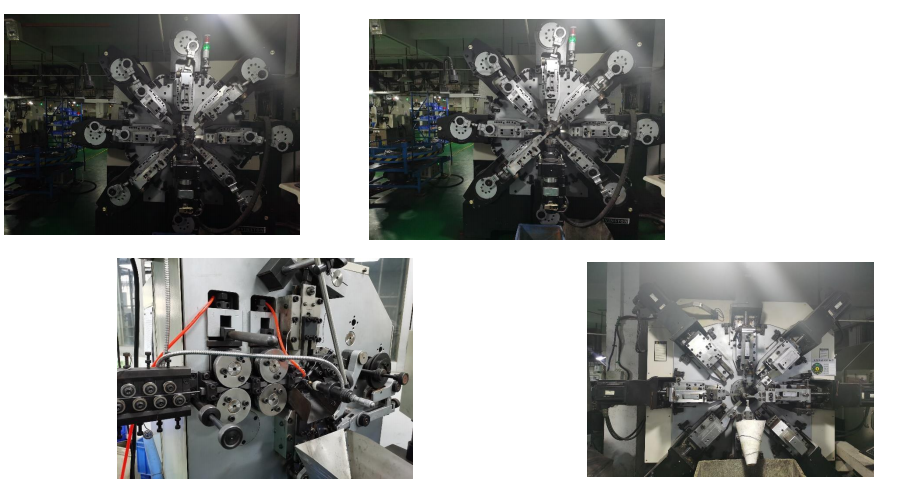

4.Metal Stamping Services

Our custom metal stamping forming service is suitable for multiple industries, including automobiles, aerospace, manufacturing, etc., which can meet the different needs of customers. Our team has rich experience and professional knowledge and can provide customers with high -quality metal stamping forming services and technology support.Our metal stamping service can provide prototype solutions for custom metal parts, contact us today to start your project.

4.1Metal Stamping Forming Parts Material

Longsheng provides the following materials for standards and custom metal stamping parts:

| Material | Elaborate |

| Steel | CRS steel, such as 1008, 1010 or 1018 is very popular; universal materials are very suitable for cold molding. |

| Stainless steel | For example, 301, 304 and 316/316L. 301 stainless steel has excellent tensile strength, while 304 has more significant performance and corrosion resistance at higher temperatures. 316/316L steel has the best corrosion resistance of the three, but its cost is also higher. |

| Copper | Including C110, it is a powerful conductor and is easy to form. |

| Bronze | Bonor 230 (85/15) and 260 (70/30) have high moldability and corrosion resistance. These brass alloys are also called red brass and puffiness, respectively. |

4.2 Metal Stamping Parts Production Base

longsheng have a team of technically strong and experienced professionals who can provide customers with professional technical support and after-sales service. We adhere to the principle of “quality first, customer first” and are dedicated to serving our customers.If you have any processing needs or questions, please feel free to contact us. We look forward to working with you!

4.3 Advantages of metal stamping

※High-Quality Parts

※Cost-Effective

※Customization

※Expertise

5.Rapid Prototyping Services

By offering minimal cost solutions, your services make it more accessible for startups and businesses with limited budgets to create high-quality prototypes. This can help foster innovation and entrepreneurship.Rapid prototyping enables designers to validate their concepts and designs before committing to full-scale production. When choosing Longsheng, customers have the method to choose the most suitable one for their project needs. Whether it’s 3D printing, CNC machining, or other technologies.

5.1 LongSheng Rapid Prototyping Capabilities

Rapid CNC Machining

Rapid CNC machining is particularly suitable for rapid prototyping of plastic and metal parts. We can manufacture all the prototypes you need through CNC machining technology and complete your rapid prototype in 3 days.

| Type | Tolerance |

|---|---|

| Linear dimension | +/- 0.025 mm (+/- 0.001 inch) |

| Hole diameters | +/- 0.025 mm (+/- 0.001 inch) |

| Shaft diameters | +/- 0.025 mm (+/- 0.001 inch) |

| Part size limit | 950 * 550 * 480 mm(37.0 * 21.5 * 18.5 inch) |

Rapid 3D Printing

Longsheng company’s most advanced SLA, SLS, FDM and other 3D printing technology. With efficient production capacity and simplified processes, we can guarantee you custom parts in as little as 1 day.

| Capabilities | Tolerance |

|---|---|

| Min. wall thickness | +/- 1.0 mm |

| Layer height | 50 – 300 μm |

| Max. build size | 600 * 600 * 600 mm |

| Tolerance | +/- 0.05 mm |

Rapid Injection Molding

Our rapid injection molding is ideal for the production of small batches of molds and large quantities of plastic parts to create products that make your brand unique.

| Capabilities | Tolerance |

|---|---|

| Mold cavity tolerances | +/- 0.05 mm |

| Standard lead time | 10 business days or less |

| Part to part repeatability | +/- 0.01 mm |

| Production grade | 1-100,000 cycles |

Rapid Sheet Metal Fabrication

Longsheng’s rapid sheet metal fabrication services enable the efficient production of metal parts. The combination of advanced equipment and in-house production ensures fast delivery and strict quality standards.

| Type | Tolerance |

|---|---|

| Bend edge straightness | +/- 0.2 mm |

| Edge to edge, single side | +/- 0.01 mm |

| Bend angle | +/- 1° |

| Hole to hole, single side | +/- 0.1 mm |

5.2 Why choose Longsheng to provide rapid prototyping services

Longsheng provides customers around the world with excellent quality, fast turnover, and cost-effective rapid prototyping services.

- No MOQ:We are flexible for one-off prototypes and low-volume parts. No matter the size of your order, we can handle it.

- Manufacturing Capabilities:We provide and support a wide range of manufacturing capabilities in CNC machining, injection molding.

- Consistent High Quality:We use high-quality materials and maintain a high level of process stability to ensure component delivery capability.

- Rapid Turnaround:Our capabilities enable us to complete your rapid prototyping project within 3 days.

5.3 Advantages of rapid prototyping

※Faster Prototyping

※Cost-Effective

※Better Quality Control

※Suitable for a Wide Range of Materials

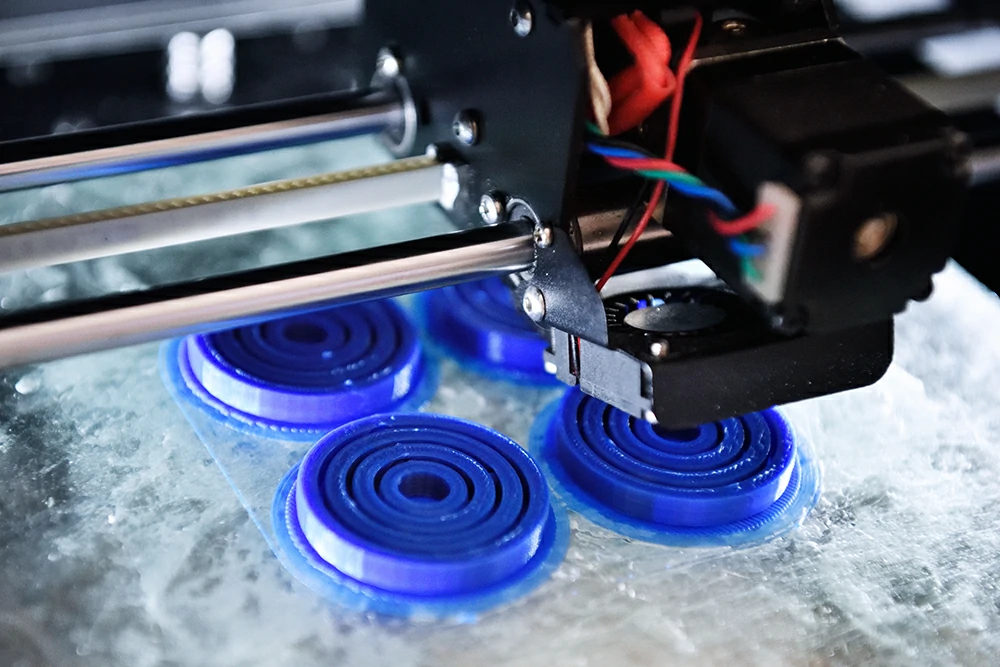

6. 3D Printing Services

Whether you need a single prototype or a large production run, we can help. Our commitment to quality and customer satisfaction ensures that you receive the best possible service and results.If you have any questions or would like to learn more about our 3D printing capabilities, please don’t hesitate to contact us. We are always happy to help and look forward to working with you.

6.1Longsheng’s 3D printing capabilities

SLA

Stereolithography (SLA) is the use of UV lasers to cure liquid resin layer by layer to create 3D objects. The technology produces highly detailed and precise parts and is ideal for applications such as rapid prototyping, product design, and dental and medical modeling.

SLS

Selective Laser Sintering (SLS) is a 3D printing technology that uses a high-powered laser to fuse powdered material layer by layer to create a 3D object. This technology is ideal for creating complex geometries and functional parts with high strength and durability.

FDM

Fused Deposition Modeling (FDM) is a 3D printing technology that involves depositing melted thermoplastic material layer by layer to create a 3D object. This technology is widely used for rapid prototyping, as well as for creating functional parts and models.

6.2 LongSheng 3D Printing Standards

Thanks to our state-of-the-art facilities and rigorous testing processes, we are able to ensure that every 3D printed prototype and part is of impeccable quality and meets extremely strict tolerances.

| Process | Layer Height Range | Minimum Wall Thickness | Maximum Build Size | Dimensional Tolerance |

|---|---|---|---|---|

| SLA | 50 – 100 μm | +/- 0.5 mm +/- 0.019 in. | 600 x 600 x 600 mm 23.622 x 23.622 x 23.622 in. | +/- 0.1 mm +/- 0.003 in. |

| SLS | 100 – 200 μm | +/- 1.0 mm +/- 0.039 in. | 420 × 500 × 420 mm 16.535 × 19.685 × 16.535 in. | +/- 0.3 mm +/- 0.011 in. |

| FDM | 100 – 300 μm | +/- 0.8 mm +/- 0.031 in. | 1000 x 1000 x 1000 mm 39.370 x 39.370 x 39.370 in. | +/- 0.2 mm +/- 0.007 in. |

6.3 Why Choose Longsheng for Online 3D Printing Services?

- Multi Material Machining:We have the ability to handle multiple materials, and we can provide professional solutions no matter what material of parts you need to process.

- Competitive Pricing:We provide competitive prices and cost-effective solutions to ensure that customers gain the greatest advantage in cost control.

- Customized Services:Provide customized solutions based on customer design requirements and specifications to ensure that parts meet their unique needs.

- Rapid Delivery:We have efficient production processes and flexible production plans, which enable us to timely deliver customer orders and meet urgent project needs.

6.4 Advantages of 3D printing

This revolutionary technology, in stark contrast to traditional subtractive manufacturing methods like machining and casting, builds objects layer by layer from digital designs, unlocking a treasure trove of advantages that have reshaped the way we think about manufacturing.

※Iterative design and prototyping

※Cost-effective for low volume production

※No upfront tooling costs

※Complex Geometries

Longsheng: Your only supplier for customized parts

With over 15 years of manufacturing experience, we handle cnc parts with tolerance of up to 0.005mm, same day quotation, and 72 hours delivery. We have produced over 80,000 different parts of different quantity. Our aim is to provide top quality and high efficiency metal parts machining services for prototyping as well as mass production customers.Longsheng has been in a leading position in similar industries in CNC processing, injection molding, sheet metal Fabrication, metal stamping, rapid prototyping, 3D printing and other services.Turn your ideas into reality with our excellent on-demand manufacturing services to produce simple and complex prototypes and final parts, all of our products meeting strict tolerances and quality requirements.

Production equipment

Our manufacturing factory is equipped with advanced production lines that can handle a variety of materials, including metals, plastics, and composites. We utilize computer-aided design (CAD) and computer-aided manufacturing (CAM) software to program our machines, ensuring high precision and accuracy in every product we create.

International Accreditation

At our manufacture factory, quality is paramount. We are proud to hold various industry certifications, including ISO 9001:2015, which ensures our processes and products meet international quality standards. We also follow strict quality control measures throughout the production process to ensure the final product is of the highest quality.

24/7 Engineering Support

Longsheng provides you with an experienced team of service engineers to solve all your manufacturing problems. Not only can we help you optimize your design and reduce costs, but our senior engineers also provide professional guidance and beneficial DFM feedback, and achieve higher quality and more consistent quality control through standardized practices to ensure that your project achieves the best results.

In Longsheng, as long as you dare to think, our team dares to do it. In the past five years, Longsheng has never stopped making progress and has always strived to provide customers with the best services. When you choose Longsheng, your custom parts are half done, and we know your time is valuable and we know you really want efficient delivery. We simplify the innovation cycle into four simple but effective steps. In just 3 days, you can get flawless parts! Take advantage of this anniversary event and start your processing projects now!