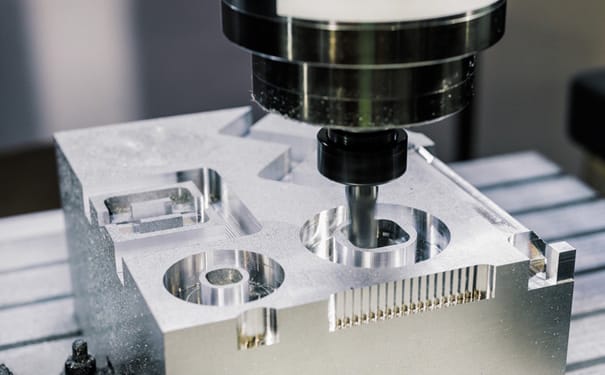

CNC machining has transformed the manufacturing industry by providing a faster, more efficient, and accurate method of producing components. The future of CNC machining is promising, and the industry is expected to undergo significant changes in the coming years.

One of the most significant trends in the future of CNC machining is the rise of smart factories. Smart factories use advanced technology and data analytics to improve operational efficiency, reduce costs, and increase productivity. In smart factories, CNC machines will be connected to a central system that can monitor and control production processes in real-time. This will allow manufacturers to optimize production, minimize downtime, and reduce waste.

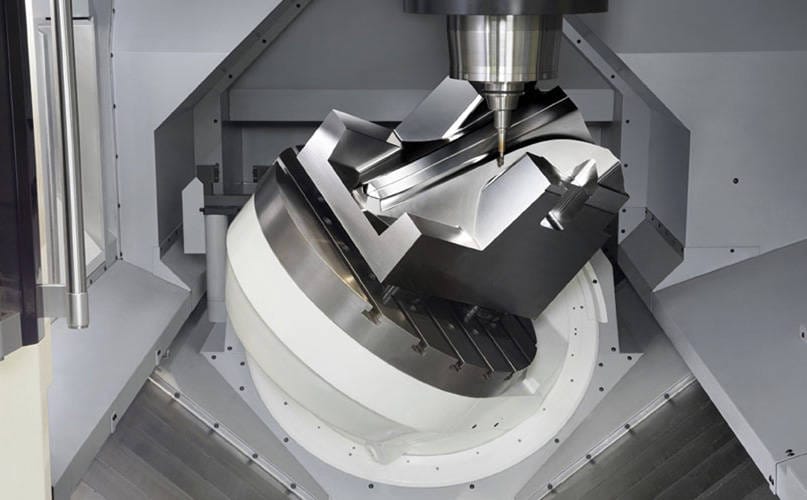

Another trend in the future of CNC machining is the use of hybrid machines. Hybrid machines combine the benefits of additive and subtractive manufacturing into a single machine. This will allow manufacturers to produce complex parts and components with greater precision and speed. Hybrid machines will also enable manufacturers to use a wider range of materials and reduce the need for multiple machines.

In addition, the use of artificial intelligence (AI) and machine learning algorithms will become increasingly prevalent in the future of CNC machining. AI and machine learning algorithms will enable CNC machines to learn from past data and adjust their operations accordingly. This will lead to more efficient and accurate production processes, reducing the risk of errors and increasing productivity.

Furthermore, the future of CNC machining will be shaped by the growth of augmented reality (AR) and virtual reality (VR) technologies. AR and VR technologies will enable manufacturers to simulate production processes and visualize the final product before it is produced. This will reduce the need for physical prototypes, saving time and money.

Moreover, the growth of cloud computing will also play a significant role in the future of CNC machining. Cloud computing will enable manufacturers to access data and software remotely, allowing them to work more efficiently and collaborate with other manufacturers worldwide. This will lead to more streamlined production processes and greater innovation in the industry.

Finally, sustainability will continue to be a significant trend in the future of CNC machining. As the world focuses on reducing carbon emissions and becoming more environmentally friendly, CNC machining will play an important role. CNC machines that use recycled materials, renewable energy sources, and energy-efficient machines will enable manufacturers to reduce their environmental impact while still producing high-quality products.

In conclusion, the future of CNC machining is bright, and the industry is poised for significant changes in the coming years. Smart factories, hybrid machines, AI and machine learning algorithms, AR and VR technologies, cloud computing, and sustainability practices will shape the industry and provide new opportunities for manufacturers to innovate and grow their businesses. Manufacturers that embrace these trends and invest in the latest technology and practices will be well-positioned to succeed in the competitive world of manufacturing.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC Milling Parts Machining Service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items