Are you interested in injection molding? Do you want to know what metal is used for molds in this process? In this blog post, we will explore the different metals used in injection molding and why they are so important. We will also discuss how the choice of metal can affect the quality and efficiency of your injection molding process.

The Importance of Metal Choice in Injection Molding

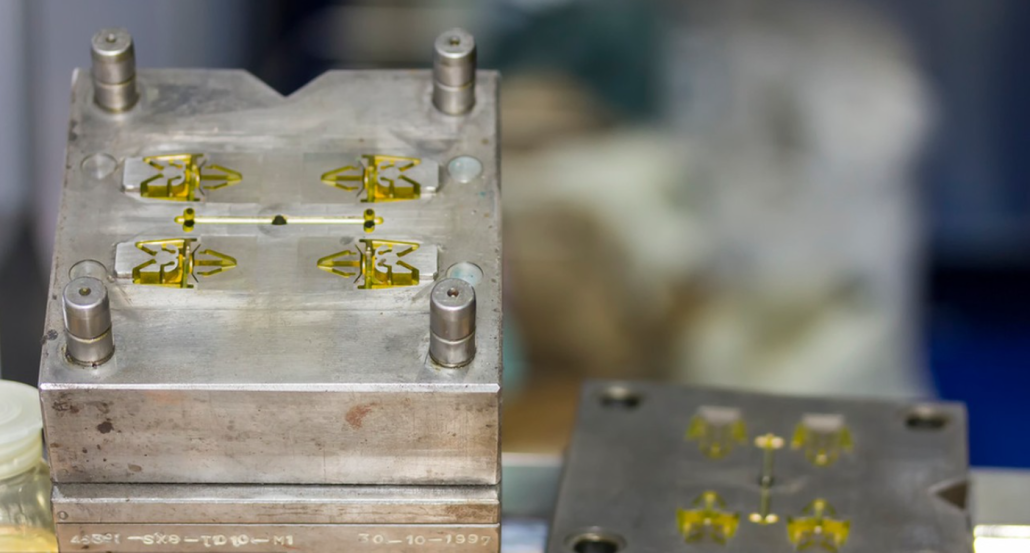

Injection molding is a manufacturing process used to create complex shapes and parts by injecting molten plastic or other materials into a mold. The mold itself is a critical aspect of the process, as it determines the final shape and quality of the product.

Choosing the right metal for your mold is crucial, as it will affect the mold’s durability, strength, and resistance to wear and tear. The material must also be able to withstand high pressure and temperatures, as well as chemical exposure.

So, what metal is used for molds in injection molding? There are several options, each with its own advantages and disadvantages.

Common Metals Used in Injection Molding

Aluminum – Aluminum is a popular choice for injection molding due to its high thermal conductivity, which allows for faster cooling and shorter production times. It is also lightweight and corrosion-resistant. However, it is not as strong as other metals and may be prone to warping or distortion.

Steel – Steel is a strong and durable material that can withstand high temperatures and pressures. It is also resistant to wear and corrosion, making it an ideal choice for long-lasting molds. However, steel molds can be expensive to manufacture and may require longer lead times.

Tool Steel – Tool steel is a specialized form of steel that is used to make high-precision molds. It is extremely hard and wear-resistant, able to withstand repeated use without losing its shape. However, it is also more expensive than other materials and may require additional maintenance.

Copper – Copper is a soft metal that is often used for small-scale injection molding projects. It has excellent thermal conductivity, allowing for fast cooling times, and is also highly corrosion-resistant. However, it is not as strong as other materials and may be prone to deformation.

Which Metal is Right for You?

When choosing a metal for your injection molding project, you must consider several factors, such as the size and complexity of the part, production volume, and cost. Each metal has its own unique properties and advantages, so it is essential to understand your specific needs and requirements.

If you need a quick turnaround time or are working with a small-scale project, aluminum may be a suitable choice. For larger-scale projects or long-term use, steel or tool steel may be

preferred for their durability and strength. Copper may be an excellent option for small, short-term projects or for parts that require high thermal conductivity.

Final Thoughts

In conclusion, the choice of metal for your injection molding mold is a critical aspect of the process. Each metal has its own unique properties and advantages, so it is important to understand your specific needs and requirements. Whether you choose aluminum, steel, tool steel, or copper, ensure that it is the best choice for your project based on factors such as strength, durability, cost, and thermal conductivity. With the right metal and a careful design, you can create high-quality, complex parts with ease using the injection molding process.