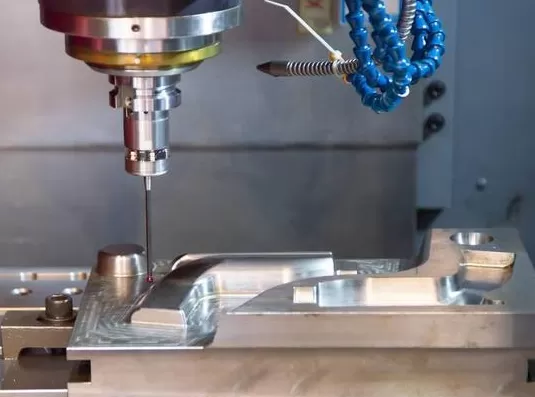

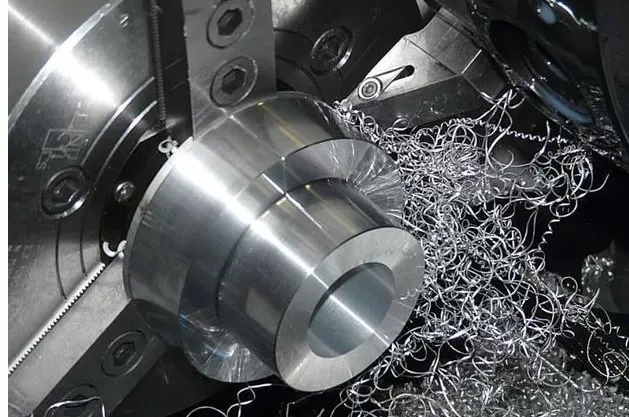

CNC machining has become an essential process in modern manufacturing, providing a faster, more efficient, and accurate method of producing components. The use of robotics in CNC machining has further revolutionized the industry, enabling manufacturers to automate production processes and increase productivity.

Benefits of Robotics in CNC Machining

Robotic systems provide several benefits to CNC machining, including:

Increased Efficiency and Productivity

Robotic systems are highly efficient and can operate around the clock with minimal supervision, increasing production capacity and reducing lead times. This allows manufacturers to produce more parts and components in less time, improving their bottom line.

Improved Precision and Accuracy

Robotic systems are highly precise and can perform repetitive tasks with extremely high accuracy. This ensures that the finished product meets the exact specifications required, reducing the risk of errors and improving quality.

Reduced Labor Costs

Robotic systems can perform tasks that would otherwise require human labor, reducing the need for manual labor and lowering labor costs. This also reduces the risk of workplace injuries and accidents, improving workplace safety.

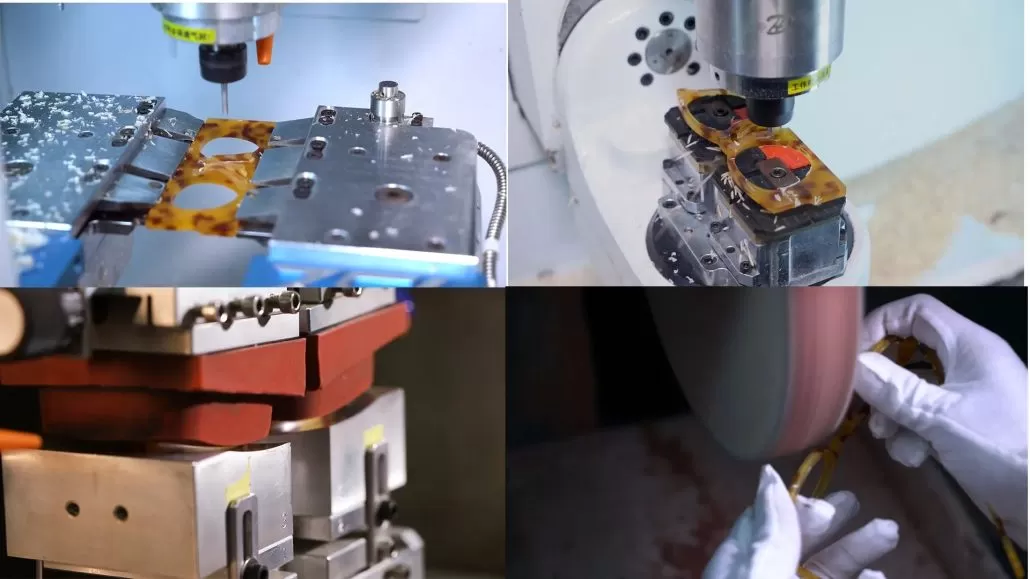

Applications of Robotics in CNC Machining

Robotic systems are used in a wide range of CNC machining applications, including:

Material Handling

Robotic systems can be used to move raw materials and finished products between machines, reducing the need for manual labor and improving efficiency.

Assembly

Robotic systems can be used to assemble complex parts and components, reducing the risk of errors and improving quality.

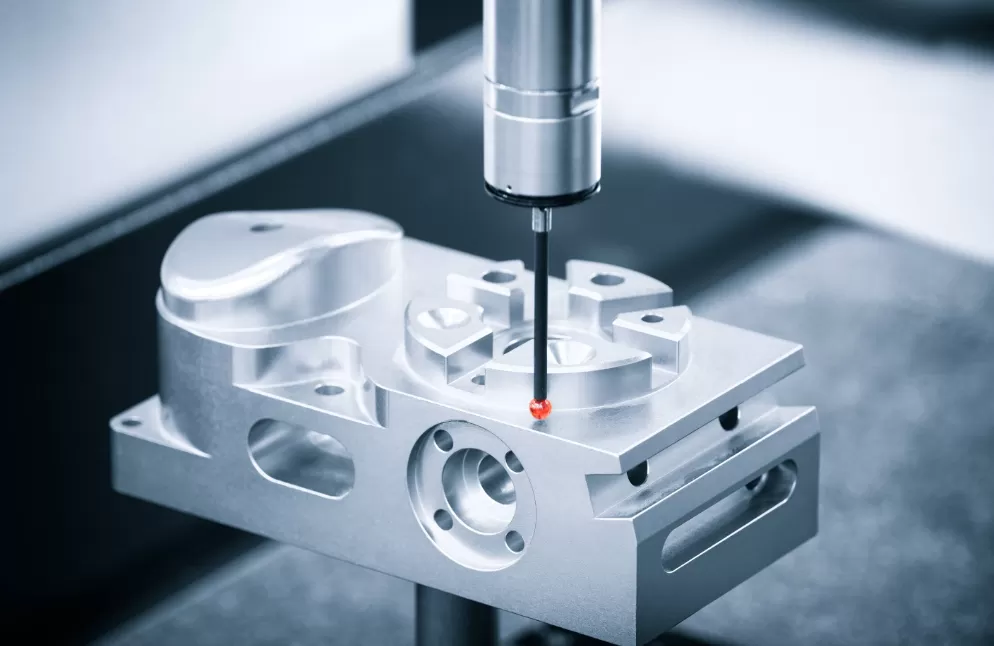

Inspection

Robotic systems can be used to inspect finished products and identify any defects or issues, improving quality control and reducing waste.

Conclusion

The use of robotics in CNC machining has revolutionized the manufacturing industry, providing increased efficiency, improved precision and accuracy, and reduced labor costs. Robotic systems are used in a wide range of applications, from material handling to assembly and inspection. As the industry continues to evolve, the use of robotics in CNC machining is expected to become even more widespread, providing new opportunities for manufacturers to innovate and grow their businesses.

If you are looking to improve the efficiency and productivity of your CNC machining operations, consider incorporating robotic systems into your manufacturing process. By doing so, you can increase production capacity, improve quality, and reduce labor costs, enabling your business to remain competitive in the rapidly changing world of manufacturing.

Advancements in Robotics for CNC Machining

Advancements in robotics technology have further improved the capabilities of robotic systems in CNC machining. One of the most significant advancements is the development of collaborative robots, also known as cobots.

Cobots are designed to work alongside human operators, performing tasks that would be difficult or dangerous for humans to perform alone. They are equipped with sensors and safety features that allow them to operate safely in close proximity to humans.

Cobots are ideal for applications such as material handling and assembly, where they can work alongside human operators to improve efficiency and productivity. They can also be easily programmed and reprogrammed, making them highly versatile and adaptable to changing production needs.

Another advancement in robotics technology is the use of artificial intelligence (AI) and machine learning algorithms. AI and machine learning algorithms can be used to optimize robotic systems for specific tasks, improving efficiency and accuracy.

For example, AI and machine learning algorithms can be used to optimize the movement of robotic arms in material handling applications, reducing the time required to move raw materials and finished products between machines. They can also be used to identify patterns in production data and adjust production processes accordingly, improving quality control and reducing waste.

Future of Robotics in CNC Machining

The future of robotics in CNC machining is promising, and the industry is expected to undergo significant changes in the coming years. One of the most significant trends in the future of robotics for CNC machining is the development of even more advanced cobots.

Advanced cobots will be equipped with even more advanced sensors and safety features, allowing them to work even more closely with human operators. They will also be equipped with more advanced AI and machine learning algorithms, enabling them to optimize production processes even further.

Another trend in the future of robotics for CNC machining is the use of swarm robotics. Swarm robotics involves the use of multiple robots working together to perform a task. This approach can be used to improve efficiency and productivity in CNC machining applications.

In addition, the use of virtual and augmented reality technologies is expected to become more widespread in CNC machining. These technologies can be used to simulate production processes and visualize the final product before it is produced, reducing the need for physical prototypes and saving time and money.

Conclusion

The use of robotics in CNC machining has revolutionized the manufacturing industry, providing increased efficiency, improved precision and accuracy, and reduced labor costs. Advancements in robotics technology, such as the development of cobots and the use of AI and machine learning algorithms, have further improved the capabilities of robotic systems in CNC machining.

As the industry continues to evolve, the use of robotics in CNC machining is expected to become even more widespread, providing new opportunities for manufacturers to innovate and grow their businesses. If you are looking to improve the efficiency and productivity of your CNC machining operations, consider incorporating robotic systems into your manufacturing process. By doing so, you can increase production capacity, improve quality, and reduce labor costs, enabling your business to remain competitive in the rapidly changing world of manufacturing.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC Milling Parts Machining Service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items