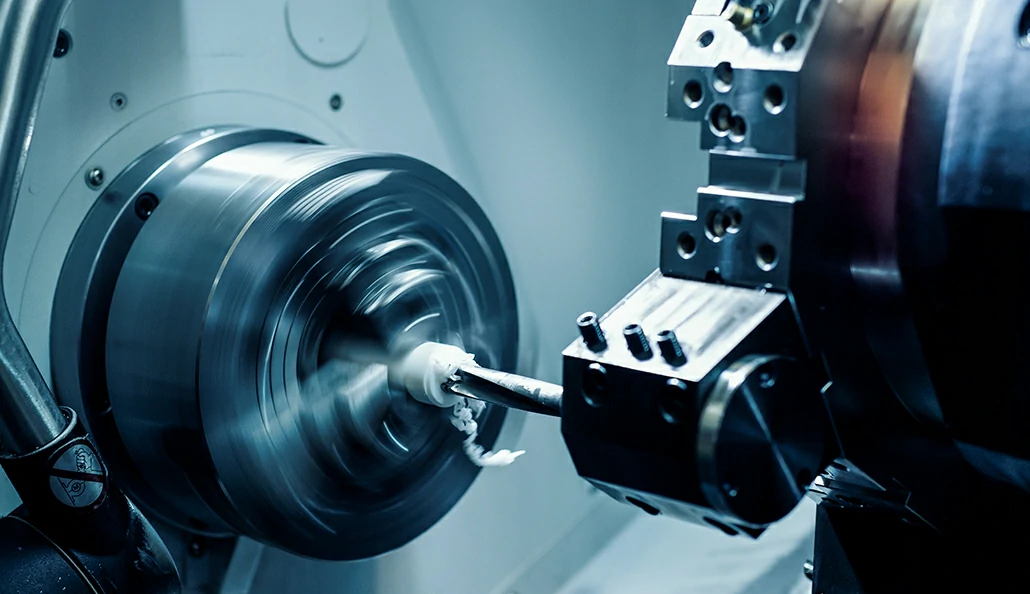

CNC machining is a method of manufacturing that utilizes computer software to control machine tools. The lathe is one of the most commonly used machine tools in CNC machining. It is versatile and can be used for a multitude of tasks, including cutting, drilling, and shaping a wide range of materials.

There are several lathe methods that can be used in CNC machining, each with its own unique advantages. The methods include turning, facing, drilling, boring, and threading.

Turning

Turning is the most common lathe method used in CNC machining. It involves rotating the workpiece while a cutting tool removes material from the surface. Turning can create a variety of shapes, including cylinders, cones, and spheres. It is used to make shafts, hubs, and other cylindrical components.

Facing

Facing is a lathe method used to create a flat surface on the end of a workpiece. The cutting tool moves perpendicular to the axis of rotation to remove material from the end of the workpiece. This method is used to create flat surfaces on workpieces such as gears, bearings, and pulleys.

Drilling

Drilling is a lathe method used to create holes in a workpiece. A drill bit is used to remove material from the workpiece in a circular motion. Drilling is used to create holes in a wide range of materials, including metal, plastic, and wood.

Boring

Boring is a lathe method used to enlarge an existing hole in a workpiece. The cutting tool moves in a circular motion while removing material from the inside of the hole. Boring is used to create precise holes in a wide range of materials, including metal, plastic, and wood.

Threading

Threading is a lathe method used to create threads on a workpiece. The cutting tool moves in a helical motion while removing material from the surface of the workpiece. Threading is used to create threads on bolts, screws, and other threaded components.

In conclusion, there are several lathe methods that can be used in CNC machining. Each method has its own advantages and is used to create specific shapes and features on a workpiece. CNC machining has revolutionized the manufacturing industry, making it possible to produce complex parts with high precision and accuracy. With the use of lathe methods, CNC machining has become even more versatile, allowing for the creation of a wide range of components for various industries.