What Are the Material Characteristics of Titanium and Aluminum?

When it comes to CNC machining, aluminum CNC machining and CNC titanium machining are commonly compared due to their unique properties. Both materials are valued for their lightweight and strength, making them ideal for precision applications. Titanium, known for its high tensile strength and corrosion resistance, is favored in high-stress environments like aerospace and medical industries. On the other hand, aluminum is lightweight, easily machinable, and cost-effective, making it suitable for automotive and consumer electronics. Table: Key Material Properties

| Property | Titanium (Ti 6Al-4V) | Aluminum 6061-T651 |

|---|---|---|

| Tensile Strength | 138 ksi (951 MPa) | 40 ksi (276 MPa) |

| Elongation | 14% | 17% |

| Hardness | 35 HRC (Rockwell) | 95 HBW (Brinell) |

| Density | 4.5 g/cm³ | 2.7 g/cm³ |

How Does Titanium Benefit CNC Machining?

CNC titanium machining offers several benefits that make it an excellent choice for high-performance parts:

- Exceptional Strength: Titanium’s high strength-to-weight ratio ensures that machined parts are durable without being overly heavy, making it ideal for aerospace applications where every ounce matters.

- Corrosion Resistance: Titanium naturally forms an oxide layer, providing outstanding resistance to corrosion. This property makes it suitable for harsh environments, including marine and chemical processing industries.

- Biocompatibility: Titanium’s compatibility with the human body makes it perfect for medical implants and devices, where it is safe and non-reactive.

- High Melting Point: Titanium’s ability to withstand high temperatures makes it a reliable choice for components exposed to extreme heat, such as jet engines.

Why Choose Aluminum Alloys in CNC Machining?

Aluminum CNC machining is favored for several reasons, particularly in industries where weight reduction and cost-efficiency are critical:

- Lightweight Nature: Aluminum’s low density makes it perfect for applications requiring light, strong components, such as in the automotive industry.

- Good Machinability: Aluminum is easy to machine, which speeds up production and reduces costs. It’s also versatile, allowing for the creation of complex geometries with high precision.

- Thermal Conductivity: Aluminum’s excellent thermal properties make it ideal for components like heat sinks in electronics, where efficient heat dissipation is crucial.

- Cost-Effectiveness: Aluminum is abundant and less expensive to process than titanium, making it a cost-effective option for large-scale production.

How to Decide Between Titanium and Aluminum: Key Factors

Choosing between titanium and aluminum for CNC machining depends on the specific needs of your project. Consider the following factors:

- Strength vs. Weight: If strength is paramount, CNC titanium machining might be the better choice. For projects where weight is a significant concern, aluminum CNC machining could be more suitable.

- Cost: Titanium is more expensive due to its material costs and machining difficulties. Aluminum, being cheaper and easier to machine, is ideal for budget-sensitive projects.

- Corrosion Resistance: Titanium’s superior resistance to corrosion makes it the best choice for harsh environments, while aluminum can be treated to enhance its corrosion resistance.

Why Costs Differ Between CNC Machined Titanium and Aluminum Parts

The cost of CNC machining parts made from titanium versus aluminum can vary significantly due to several factors:

- Material Cost: Titanium is more expensive to source and process compared to aluminum, making it a higher initial investment.

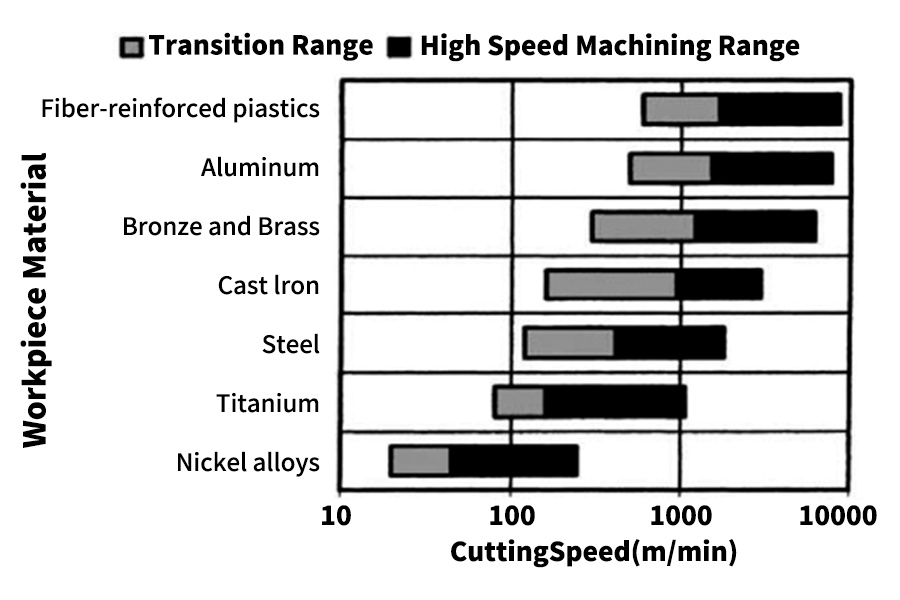

- Machining Speed: Titanium’s hardness requires slower machining speeds, which increases production time and costs. Aluminum, being softer, can be machined faster and more economically.

- Tool Wear: Titanium’s toughness leads to faster tool wear, necessitating more frequent tool changes and higher operational costs. Aluminum’s machinability reduces tool wear, contributing to lower costs.

- Post-Processing: Titanium often requires additional post-processing, such as heat treatment or surface finishing, further increasing costs. Aluminum typically needs less intensive post-processing.

Summary

Both titanium and aluminum offer unique advantages in CNC machining, with each material excelling in different aspects. CNC titanium machining is unmatched in strength and corrosion resistance, making it ideal for demanding applications in aerospace and medical fields. Aluminum CNC machining, on the other hand, offers excellent machinability, cost-effectiveness, and lightweight properties, making it a versatile choice for automotive, electronics, and consumer products. The choice between these materials ultimately depends on the specific requirements of your project, including strength, weight, cost, and environmental considerations.

FAQs

-

Is titanium lighter than aluminum?

- No, titanium is denser and heavier than aluminum. However, due to its high strength, less titanium is needed to achieve the same structural integrity, balancing out the weight difference.

-

Is titanium stronger than aluminum?

- Yes, titanium is significantly stronger than aluminum, making it ideal for high-stress applications where durability is crucial.

-

Are both titanium and aluminum recyclable?

- Yes, both metals are highly recyclable and can be reused multiple times without losing their properties, making them sustainable choices for manufacturing.

Disclaimer

The content appearing on this webpage is for informational purposes only. LongSheng makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LongSheng’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LongSheng

This article was written by various LongSheng contributors. LongSheng is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

You should take part in a contest for one of the best blogs on the web. I will recommend this site!

Pingback: Discover the Strength of 2024 Aluminum in Aerospace

Pingback: Titanium CNC Machining Services | Custom CNC Lathe Parts Supplier