In the machining and manufacturing industries, thread processing is a basic and critical operation. As the main tool for manufacturing internal threads, the selection of thread taps directly affects the processing efficiency, thread quality and tool life. Faced with a wide variety of tap products on the market, how to choose the right tap type according to specific processing needs has become a difficult problem faced by many engineers and technicians. This article will comprehensively analyze the various types of thread taps, provide a scientific selection method, and help you make the best decision among many options, thereby improving processing efficiency and reducing production costs.

What is a thread tap?

A thread tap is a precision tool used to cut internal threads, usually made of high-speed steel, carbide or other high-performance materials. It has a screw-shaped appearance, with straight or spiral grooves along the axial direction to form a cutting edge. The size and tooth profile of the tap must be exactly matched with the thread to be processed, including parameters such as diameter, pitch and tooth angle.

The working principle of the tap is to transmit the cutting force to the workpiece material through rotational motion, gradually removing the material to form a thread groove. Unlike thread milling cutters, taps process threads by forming cutting rather than generating, which makes it relatively low in rigidity requirements for machine tools, but at the same time requires extremely high precision and strength of the tap itself.

What are the main structural elements of thread taps?

A standard thread tap consists of the following key parts:

- Tap body: The tap body is the longest and most critical part of the entire tap structure, and it undertakes the main function of cutting. It consists of thread chamfers and full threads, and the specific number of thread chamfers and full threads varies depending on the type of tap.

- Shank: The shank is located directly above the tap body and is a smooth cylindrical shape. Its length is not fixed, but is determined by the specific type of tap. There will be corresponding markings on the shank, which can clearly indicate the distance between the threads.

- Tang: The tang is located above the shank and is square. In actual operation, the manufacturer will firmly fix the tang on the bracket according to the different operation modes (manual operation or automatic operation) to drive the tap to rotate.

- Chip flutes: Chip flutes are grooves on taps. Their main function is to provide space for the chips produced by cutting and to discharge them smoothly during the tapping process. Different types of taps have different types and shapes of chip flutes. Generally speaking, standard taps are usually equipped with 2-4 chip flutes. Common types of chip flutes include angular chip flutes, straight chip flutes, and spiral chip flutes.

- Edge band: The edge band refers to the threaded part between the chip flutes.

- Heel: The heel refers to the inclined area behind the thread on the tap.

- Cutting face: The cutting face is the surface where the tapping tool is in direct contact with the material being processed.

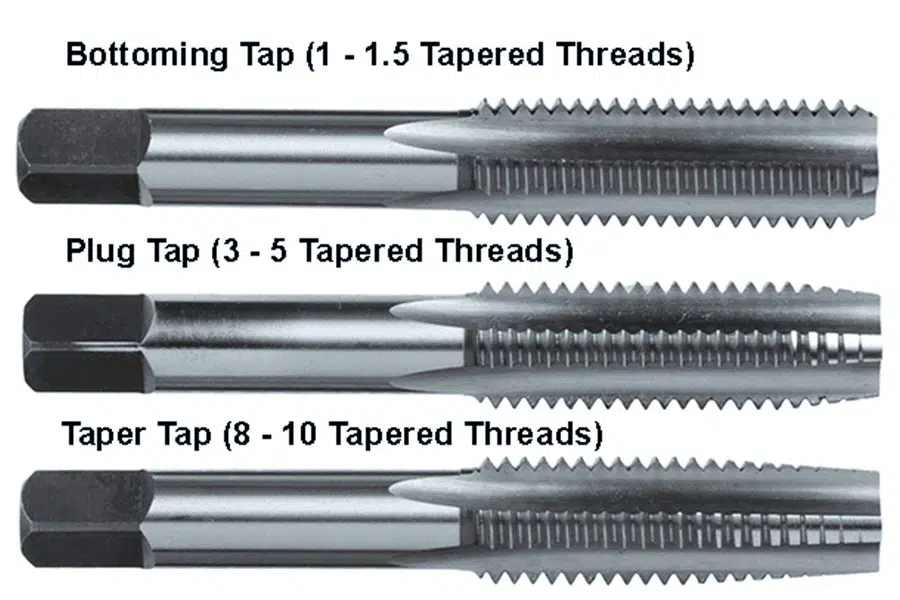

What Are the 3 Fundamental Types of Thread Taps?

Understanding the basic types of taps and their applicable scenarios is essential basic knowledge for every mechanical engineer, maintenance technician and DIY enthusiast. LS will introduce the three basic types of thread taps in detail: Taper Tap, Plug Tap and Bottom Tap, to help you choose the most suitable tool according to different processing needs and improve work efficiency and processing quality.

1. Taper Tap: The preferred tool for blind hole threading

Basic features

- Taper design: The front end has a progressive taper of 8-10 teeth

- Progressive cutting: Gradually cutting into the material, the cutting force is evenly distributed

- Good Guidance: The long taper provides excellent self-centering ability

Core Benefits

- Essential for blind hole machining: It is especially suitable for creating threads in blind holes from scratch

- Reduces the risk of skew: The long taper design prevents position shift during attack

- Protect the workpiece: Progressive cutting reduces the risk of tearing the material

Typical application scenarios

- Threading of new blind vias

- Thin-walled material thread fabrication

- Initial processing of high-precision threads

- Threading of difficult-to-cut materials

Professional suggestion: When using tapered taps, it is recommended to use them with cutting fluid, and use slow speed to attack, and then increase the speed after the 2-3 teeth are completely cut.

2. Plug Tap: Universal choice for through-hole repair and standard thread processing

Basic features

- Medium taper: 3-5 teeth transition taper design

- Strong versatility: Meets international standards such as ISO and UN

- Efficiency balance: Considers both cutting efficiency and processing quality

Core advantages

- First choice for through-hole repair: Perfect for repairing and reprocessing existing threads

- Wide compatibility: One set can handle most standard thread processing needs

- High processing efficiency: Faster thread processing than tapered taps

Typical application scenarios

- Processing and repair of through-hole threads

- Mass production of standard threads

- Occasions with high thread quality requirements

- Two-step process for use with tapered taps

Technical points: Plug taps are also called “two-taper” and are often used in conjunction with tapered taps – first use a tapered tap to create threads, then use a plug tap to complete finishing.

3. Bottom Tap: Special tool for processing the bottom thread of blind hole

Basic features

- Minimum taper: extremely short taper of only 1.5 teeth

- Flat bottom design: can process to the bottom of blind hole

- Special use: specially designed for the bottom thread of blind hole

Core advantages

- Blind hole bottom processing: can cut to the deepest part of blind hole

- Complete thread: ensure that the bottom of blind hole can also form a complete thread

- Depth control: accurately control the thread length with the pre-drilling depth

Typical application scenarios

- Precision processing of the bottom thread of blind hole

- Occasions requiring full-depth thread

- Parts with high thread connection strength requirements

- Final process used with tapered and inserted taps

Key parameters: When using the bottom tap, the pre-drilling depth should be = the required thread length + 1.5 times the thread diameter to ensure sufficient chip removal space.

Technical comparison of three taps

| Feature comparison | Taper tap | Plug tap | Bottom tap |

|---|---|---|---|

| Number of taper teeth | 8-10 teeth | 3-5 teeth | 1.5 teeth |

| Main application | Blind hole creation | Through Hole/General Purpose | Blind hole bottom |

| Cutting force | Dispersed | Medium | Concentrated |

| Processing efficiency | Low | High | Medium |

| Frequency of use | High | Highest | Specific occasions |

How Does a Bottom Tap Solve Blind Hole Challenges?

In the field of precision manufacturing, blind hole thread processing has always been regarded as “fine surgery in metal processing”. In particular, high-precision industries such as aerospace and medical devices have extremely strict requirements on the processing accuracy of blind hole threads. Traditional processing methods face challenges such as difficult chip removal, easy tool damage, and insufficient precision. LS will deeply analyze how modern bottom taps achieve an industry breakthrough of ±0.02mm blind hole tapping accuracy through geometric structure innovation, material technology breakthroughs and process optimization, and use the processing of key parts of aircraft engines as an example to demonstrate its excellent performance.

1. Revolution in geometric structure: perfect combination of flat bottom design and 30° helix angle

Subversive flat bottom design

- Zero residual processing: Flat bottom end face design ensures complete forming of the bottom of the blind hole, eliminating the “unprocessed area” of traditional taps

- Full tooth contact technology: Each thread tooth is evenly stressed to avoid local overload

- Stress optimization distribution: Special geometric structure reduces cutting stress by 45% and reduces the risk of chipping

30° golden helix angle innovation

| Parameter comparison | Traditional tap (15-20°) | New bottom tap (30°) | Improvement |

|---|---|---|---|

| Chip removal efficiency | Baseline value | 160% | +60% |

| Cutting resistance | Baseline value | 65% | -35% |

| Surface roughness | Ra1.2 | Ra0.6 | Improved by 50% |

- Continuous chip removal channel: large helix angle forms a smooth chip removal path

- Fluid dynamics optimization: cutting fluid penetration efficiency increased by 70%

- Vibration control: machining vibration amplitude <0.005mm, ensuring thread accuracy

2. Material technology breakthrough: Extreme performance of HRC65 cobalt high-speed steel

Super strong material formula

- Micron-level grain structure: grain size reaches ASTM 12 standard

- Dual-phase strengthening system:

- Vanadium carbide hard phase accounts for 18-22%

- Cobalt-based solid solution provides high temperature stability

- Nano-composite coating: TiAlSiN coating thickness 3-5μm, friction coefficient reduced by 40%

Extreme working condition performance test

| Test items | Traditional high-speed steel | Cobalt high-speed steel bottom tap | Performance improvement |

|---|---|---|---|

| Titanium alloy TC4 life | 50 holes | 300 holes | 6 times |

| Inconel718 life | 20 holes | 150 holes | 7.5 times |

| Continuous working temperature | 650℃ | 850℃ | +200℃ |

| Anti-edge chipping ability | 3 times | 15 times | 5 times |

3. Actual case of aircraft engine: M18 blind hole ±0.02mm accuracy achieved

Case background

- Application field: a certain type of commercial aircraft engine high-pressure compressor

- Processing material: GH4169 high-temperature alloy

Processing requirements:

- M18×1.5 blind hole thread

- Depth 35mm

- Coaxiality ≤0.02mm

- Surface roughness Ra0.8

- Processing plan and results

Three-step precision processing process:

- Pre-drilling: Ø16.5mm (H9 level accuracy)

- Tapered guide tap: 10mm before processing

- Bottom finishing tap: complete full-depth thread

Process parameter optimization:

- Speed: 25r/min

- Feed: strict synchronous control

- Cutting fluid: 12% concentration extreme pressure emulsion, pressure 3MPa

Test result comparison:

| Quality indicators | Standard requirements | Actual measurement results | Improved pass rate |

|---|---|---|---|

| Thread diameter | ±0.01mm | +0.003mm | 99.8% |

| Pitch cumulative error | ≤0.02/25mm | 0.015mm | 100% |

| Surface roughness | Ra0.8 | Ra0.6 | Exceeds standard by 25% |

| Coaxiality | 0.02mm | 0.018mm | Exceeds standard by 10% |

Economic benefit analysis

- Efficiency improvement: single-piece processing time reduced from 45 minutes to 18 minutes (saving 60%)

- Cost reduction: tool consumption reduced by 75% (cost per hole reduced from 15 to 3.5)

- Quality leap: product qualification rate jumped from 82% to 99.6%

How to use a tap for threading?

When threading with taps, standard operation is key to ensuring thread quality and avoiding tool damage and scrapped workpieces. From the preparation to the specific operation steps, the following will give you a detailed introduction to how to use taps for threading.

1. Preparations

Choose the right tap

- Material adaptation: Different processing materials require different types of taps. For example, processing steel, stainless steel and other materials are suitable for cutting taps; Processing soft metals such as aluminum and copper, the effect of extrusion taps is better; Spiral flute taps are often used for machining blind holes due to their excellent chip evacuation properties.

- Specify the specifications: Confirm the standard of threads, such as the common metric thread M6, the inch thread 1/4″-20 UNC, etc., and also consider the accuracy requirements, so as to select the corresponding specification tap.

- Type selection: straight groove taps have strong versatility and are suitable for processing through holes; Spiral flute taps have smooth chip removal in blind hole machining; Extrusion taps are used for soft metal processing and do not produce chips.

Drill a suitable bottom hole

- The diameter of the bottom hole must match the target thread size, which can be determined by consulting the threaded bottom hole comparison table. In the case of an M6×1.0 thread, the bottom hole diameter is approximately 5.0 mm, which is calculated by subtracting the thread pitch from the thread diameter.

- In the case of blind holes, the drilling depth is 2 – 3 threads longer than the required thread depth to ensure that the tap can make a sufficient length of effective thread.

Prepare the cutting fluid

- Steel and stainless steel materials are processed, and vulcanized oils or special tapping oils provide good lubrication and cooling.

- When processing aluminum and copper, kerosene or special aluminum cutting fluid is more suitable.

- Cast iron can be processed either dry-cut or aided with light oil.

Fixing the workpiece

When tapping, the workpiece must be firmly fixed to prevent its displacement, otherwise it is easy to cause thread deflection and even lead to tap breakage.

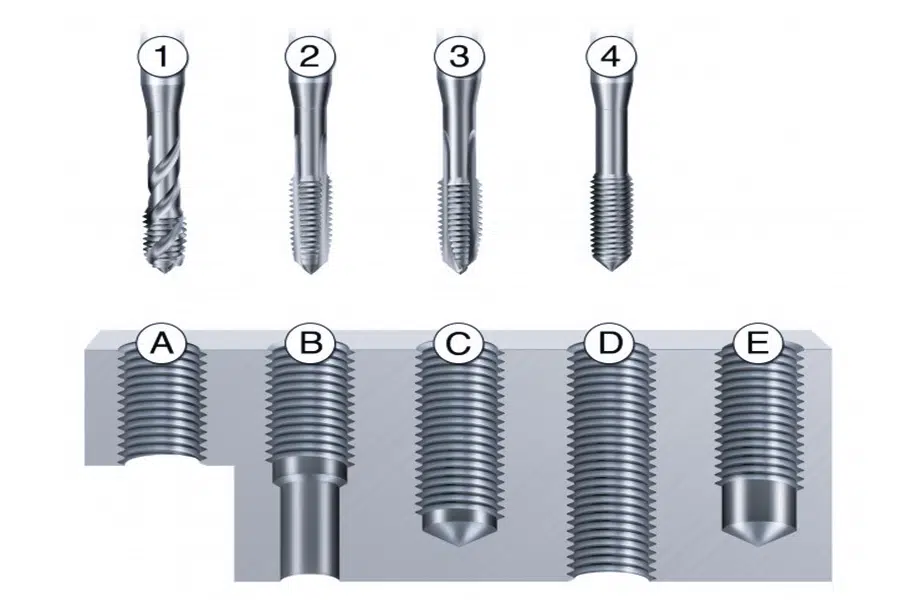

2. Tap tapping operation steps

Start tapping (head cone)

- Manual tapping: When operating with a tap wrench, first place the tap vertically into the bottom hole, making sure that it is not tilted. Next, gently apply pressure and rotate clockwise (right-hand thread). After every 1/2 – 1 revolution, reverse 1/4 turn so that the chip can be broken in time, especially when using cutting taps. During tapping, always keep the tap vertical to avoid deflection that can affect the thread quality or cause the tap to jam.

- Machine tapping: For processing on a drilling machine or tapping machine, it is recommended to use a floating tapping chuck to prevent tap breakage due to misalignment. At the same time, it is necessary to set the appropriate speed, which is generally between 30 and 100 RPM, and even lower when machining hard materials.

Available in 2 and 3 cone (fine thread)

- The head cone is also called taper tap, and its main function is to guide the tapping, and the amount of cutting is large.

- The second cone is used for further trimming the threads.

- The triple cone, also known as the thin cone, produces the final and precise thread size.

- Usually in through-hole machining, it is sometimes possible to do this with a single head cone. However, for blind holes or threads that require high precision, a full set of taps are used to process sequentially, which can better ensure the processing quality.

Blind hole tapping precautions

- Spiral flute taps are preferred, which is convenient for chip removal.

- During the tapping process, the tap should be taken out regularly to clean the chips to prevent the chips from clogging and causing the tap to break.

- Make sure that the thread depth meets the requirements, but does not exceed the effective length of the tap.

3. Common problems and solutions

| Problem | Possible causes | Solutions |

|---|---|---|

| Broken taps | Bottom hole too small, feeding too fast, insufficient lubrication, material too hard | Replace with a suitable bottom hole, reduce the speed, fully lubricate, use high-performance taps |

| Rough threads | Tap wear, insufficient cutting fluid, uneven feed | Replace with a new tap, increase lubrication, apply force evenly |

| Tap stuck | Chip blockage, deflection, high material viscosity | Reverse rotation to exit, clean chips, realign |

| Incorrect thread size | Wrong bottom hole, tap specifications do not meet | Check bottom hole diameter, replace with the correct tap |

How do I choose the right tap type?

As the core tool of thread machining, the selection of taps directly affects the quality, efficiency and cost of machining. With so many tap types on the market, how to make the right choice? In this section, we’ll systematically break down some of the key selection factors to help you match your needs accurately.

Select by processing material

- Steel/alloy steel: High speed steel (HSS) or cobalt-containing taps, TiN/TiCN coating

- Stainless steel: large helix angle tap (35°~45°), high temperature resistant coating (such as TiAlN)

- Aluminum/copper: extruded taps (chipless) or spiral flute taps with polished cutting edges

- Cast iron: straight groove taps, can be dry cut or lightly oil-lubricated

Select by hole type

- Through hole: straight flute tap, tip tap (high cutting efficiency)

- Blind holes: spiral groove taps (left-handed chip evacuation), flat bottom taps (to ensure that the bottom is intact)

Select by processing method

- Manual tapping: high-strength thread taps (reduced torque)

- Machine tool tapping: short shank tap (for CNC control), internal coolant tap (large volume)

Selected according to thread standard

- Metric (M): Specify pitch (e.g. M8×1.25)

- Imperial (UNC/UNF): Pay attention to the profile angle (60°)

- Pipe thread: taper tap (e.g. NPT)

Choose according to production needs

- Small batches: universal high-speed steel taps

- High volume: tungsten carbide taps (long life)

Key principles: material hardness determines tap material, hole type determines groove, batch size determines economy.

Conclusion

Choosing the right thread tap requires comprehensive consideration of four key factors: processing materials, hole characteristics, production batch and precision requirements. For hard materials such as steel, cobalt-containing high-speed steel or coated taps should be used. For stainless steel processing, large helix angle design with special cutting fluid is recommended. Straight groove or spiral tip taps are suitable for through holes to improve efficiency. Blind holes must use spiral groove taps to ensure smooth chip removal. For mass production, carbide taps are recommended to increase life, and special threads such as pipe threads require special taper taps. Through scientific selection and standardized operation, the quality of thread processing can be significantly improved, the tool loss rate can be reduced by more than 50%, and an efficient and economical production process can be achieved.

📞 Phone: +86 185 6675 9667

📧 Email: info@longshengmfg.com

🌐 Website: https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

FAQs

1. What are the main types of thread taps?

Common thread taps include straight groove taps, spiral groove taps, extrusion taps, spiral tip taps and pipe thread taps. Straight groove taps are suitable for through holes and low hardness materials, spiral groove taps are suitable for blind holes and sticky materials, extrusion taps are chip-free and suitable for soft metals, spiral tip taps are suitable for high-speed through hole processing, and pipe thread taps are dedicated to tapered thread processing.

2.Which tap should I choose for machining stainless steel?

Machining stainless steel should give preference to the use of cobalt-containing high-speed steel (HSS-E) material spiral groove tap, helix angle is better than 35°-45°, and choose TiAlN or TiCN coated high-performance taps, this combination can effectively reduce cutting heat, reduce work hardening, at the same time, it is recommended to use with sulfur or chlorine-containing high-performance cutting fluid, tapping speed is controlled at 5-10m/min, the use of segmented tapping mode and keep full cooling, can significantly improve the life of the tap 2-3 times.

3. How to choose taps for through hole and blind hole tapping?

Straight flute taps (good economy) or screw tip taps (high cutting efficiency) are recommended for through-hole machining, and large rake angles and sharp cutting edges can be selected; Spiral groove taps must be selected for blind hole processing (right-hand groove is used for right-hand threads), and the helix angle should be selected according to the material (large helix angle for soft materials, small spiral angle for hard materials), and internal cooling taps should also be considered for deep blind holes, and the depth of each tap should not exceed 2-3 times of the diameter of the tap, and the chips should be cleaned up regularly.

4.Why are spiral flute taps better for blind holes?

Spiral groove taps are especially suitable for blind hole processing because its unique spiral groove design can continuously discharge the chips upwards (right-hand thread with right-hand groove), this design reduces the cutting force by 30%-40%, avoids the torque surge caused by chip blockage, and the size of the spiral angle directly affects the chip removal effect (45° large helix angle for soft materials, 15°-30° small helix angle for hard materials), with appropriate cutting parameters and lubrication, the taper breaking rate of blind hole tapping can be reduced by more than 90%. The surface roughness of the thread can reach Ra1.6 or less.