CNC precision machining is a manufacturing process that has revolutionized the way complex parts and components are produced. It involves the use of computer-controlled machines that are programmed to perform specific tasks according to a set of instructions entered into a computer. This technology has become an essential tool for various industries, including aerospace, automotive, medical, and electronics.

How CNC Precision Machining Works

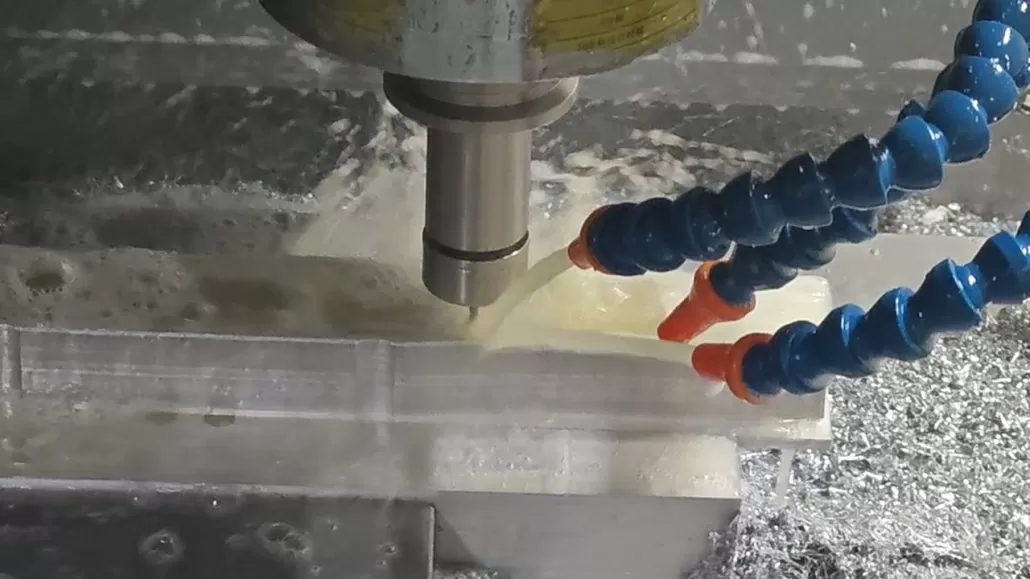

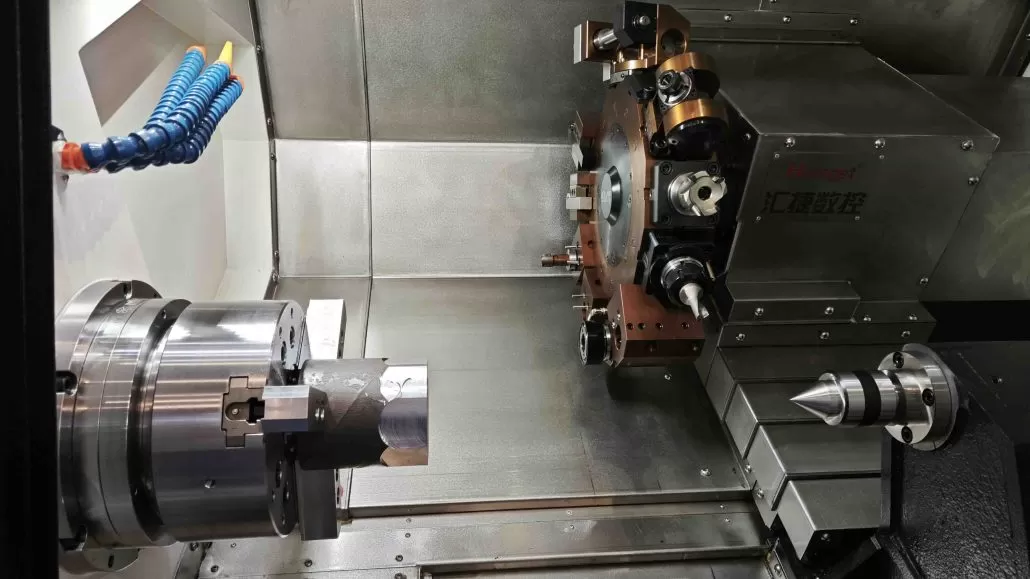

The process of CNC precision parts machining starts with a CAD (Computer-Aided Design) file that contains a 3D model of the part or component to be manufactured. The CAD file is then converted into a CAM (Computer-Aided Manufacturing) file, which contains the instructions for the CNC machine to follow. The CNC machine then uses various cutting tools, such as drills, lathes, and mills, to shape and form the part or component. The machine’s movements are precise and accurate, thanks to the computer-controlled motors that move the cutting tools along multiple axes. This results in parts and components that are consistent in size, shape, and surface finish.

Benefits of CNC Precision Machining

CNC precision machining offers several advantages over traditional manufacturing processes. One of the most significant benefits is the high accuracy and precision achieved by CNC machines. These machines can produce parts and components with tolerances as low as 0.0001 inches. Additionally, CNC machines can produce identical parts and components repeatedly, ensuring consistent quality and performance. The versatility of CNC machines allows them to produce complex shapes and designs that would be difficult or impossible to produce with traditional manufacturing processes. Finally, CNC machines can produce parts and components faster than traditional manufacturing processes, reducing lead times and increasing productivity.

Applications of CNC Precision Machining

CNC precision machining is used in various industries and applications. In the aerospace industry, CNC machines are used to produce critical components such as turbine blades, engine parts, and landing gear. In the automotive industry, CNC machines are used to produce engine blocks, transmission housings, and other components. In the medical industry, CNC machines are used to produce surgical instruments, implants, and prosthetics. Finally, in the electronics industry, CNC machines are used to produce printed circuit boards (PCBs), connectors, and other components.

Conclusion

CNC precision machining is a powerful technology that has transformed the manufacturing industry. With its high accuracy, consistency, versatility, and efficiency, it has become an essential tool for producing complex parts and components used in various applications. Whether you’re in the aerospace, automotive, medical, or electronics industry, CNC precision machining can help you produce high-quality parts and components that meet your specific requirements.

If you’re looking to take advantage of CNC precision turning parts machining for your manufacturing needs, it’s essential to partner with a reputable and experienced CNC machining company. They can help you design, prototype, and produce high-quality parts and components that meet your specific requirements while ensuring consistency, accuracy, and efficiency.