What is G-Code Programming in CNC Machining?

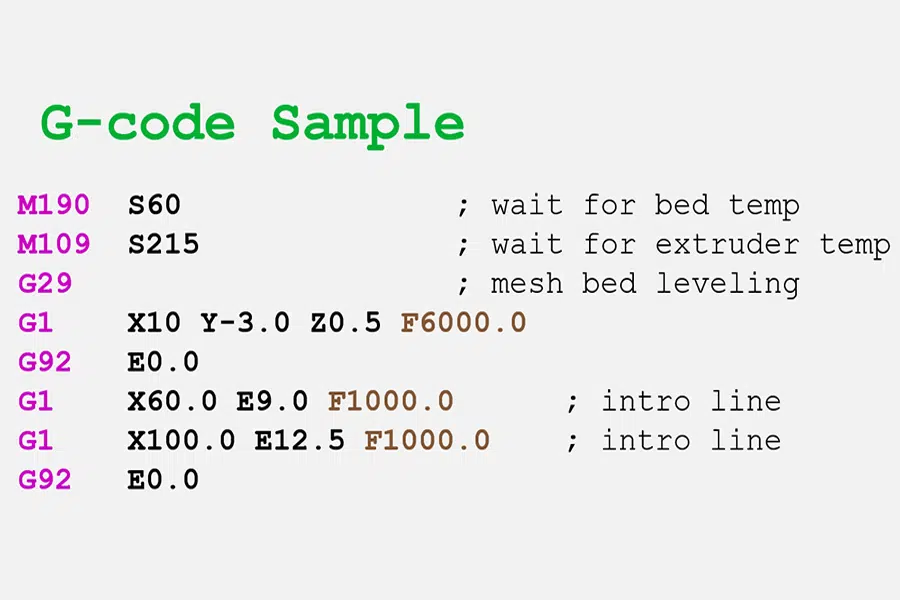

G-Code is the foundational language used in CNC machining to control machine movements and operations. It dictates the actions of CNC machines, such as those used in aluminum CNC machining, CNC plastic machining, and CNC titanium machining. By defining the geometric paths, spindle speeds, and feed rates, G-Code ensures that CNC machines execute precise and consistent machining operations, especially when producing high precision CNC machining parts.

How G-Code Influences Precision CNC Machining

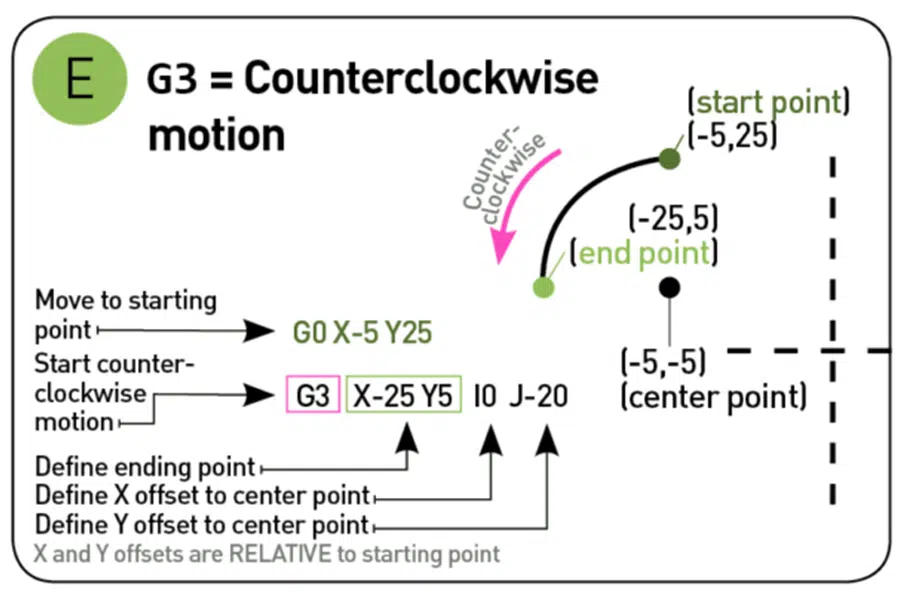

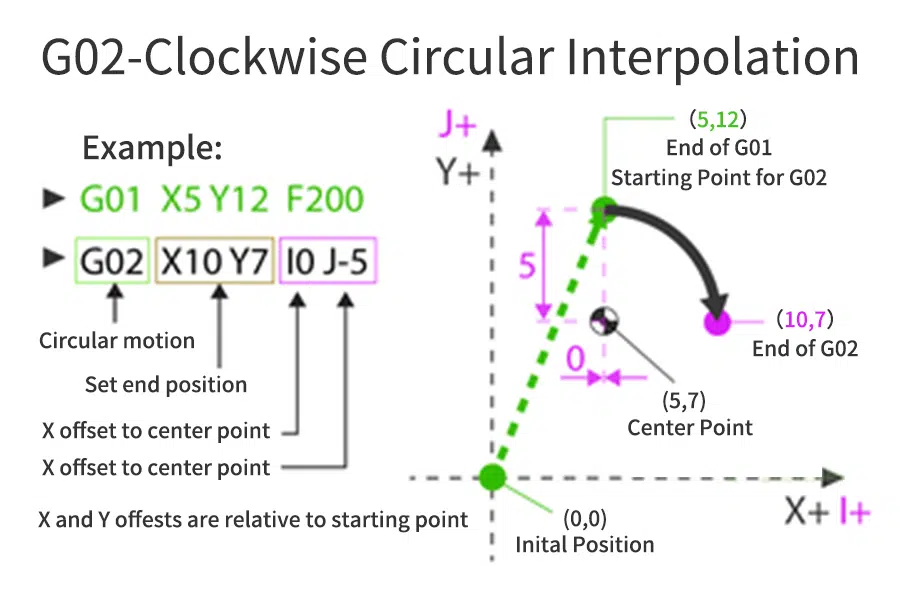

G-Code directly impacts the accuracy and quality of the final product. For example, in precision CNC machining parts, G-Code commands like G01 and G02 control linear and circular tool movements, respectively. These commands are crucial in multi-axis CNC machining, where precise tool paths are necessary to achieve the desired tolerances. By using optimized G-Code, a CNC machining parts factory can reduce tool wear, improve surface finishes, and ensure consistent part quality.

| G-Code Command | Function | Example |

|---|---|---|

| G00 | Rapid Positioning | G00 X10 Y10 |

| G01 | Linear Interpolation | G01 X10 Y20 F100 |

| G02 | Clockwise Circular Interpolation | G02 X10 Y20 I5 J5 F100 |

| G17 | Select XY Plane | G17 |

| G21 | Set Units to Millimeters | G21 |

| G90 | Absolute Positioning | G90 |

Why is G-Code Essential for Multi-Axis CNC Machining?

Multi-axis CNC machining requires complex tool paths and precise movements that only well-structured G-Code can provide. The ability to control various axes simultaneously is critical in high precision CNC machining. For example, CNC titanium machining often involves challenging geometries that need accurate, simultaneous movements of multiple axes. G-Code ensures that each axis moves in coordination, producing parts with high accuracy and intricate details.

How to Optimize G-Code for Aluminum, Plastic, and Titanium CNC Machining

Optimizing G-Code involves adjusting feed rates, spindle speeds, and tool paths to match the material being machined. For aluminum CNC machining, higher speeds and feeds may be appropriate, while CNC plastic machining might require lower speeds to avoid melting. CNC titanium machining, on the other hand, requires careful control of cutting parameters to prevent excessive tool wear and achieve high precision.

Case Studies: Successful G-Code Applications in CNC Machining

Case 1: Aluminum CNC Machining for Aerospace Components In an aerospace project, a CNC machining parts factory optimized G-Code for aluminum components, ensuring high precision in producing lightweight parts with complex geometries. The optimization included fine-tuning the feed rates and spindle speeds, resulting in a 15% reduction in machining time and improved surface finish.

Case 2: CNC Plastic Machining for Medical Devices A medical device manufacturer faced challenges with CNC plastic machining, specifically in maintaining the integrity of delicate parts. By optimizing G-Code, including lowering cutting speeds and adjusting tool paths, the factory reduced scrap rates by 25%, achieving higher precision and consistency.

Case 3: CNC Titanium Machining for High-Performance Automotive Parts Titanium’s toughness posed challenges in machining high-performance automotive parts. A CNC machining parts factory successfully optimized G-Code to minimize tool wear and achieve tight tolerances. The G-Code adjustments led to a 20% increase in tool life and consistent part quality, crucial for high-performance applications.

Important Considerations When Editing G-Code

- Material Properties: Always consider the material’s properties (e.g., hardness, melting point) when adjusting G-Code parameters to avoid issues like tool wear or part deformation.

- Machine Capabilities: Ensure that the G-Code is compatible with the CNC machine’s capabilities, especially in multi-axis CNC machining, to prevent errors or machine damage.

- Tool Path Verification: Use simulation software to verify the tool path before running the program, minimizing the risk of costly errors during actual machining.

Summary

G-Code is the backbone of CNC machining, enabling the production of precise, high-quality parts across various materials, including aluminum, plastic, and titanium. In a CNC machining parts factory, mastering G-Code is essential for successful multi-axis CNC machining and producing high precision CNC machining parts. Real-world cases demonstrate how optimized G-Code can lead to significant improvements in efficiency, part quality, and overall machining performance.

FAQs

- What is the main difference between G-Code and M-Code in CNC machining?

- G-Code controls the geometric movements of the machine, while M-Code manages auxiliary functions like spindle on/off and coolant control.

- Can G-Code be used for all materials in CNC machining?

- Yes, G-Code can be customized and optimized for various materials, including aluminum, plastic, and titanium, to achieve the desired machining results.

- How does G-Code optimization affect production efficiency?

- Optimized G-Code reduces tool wear, improves machining speeds, and ensures consistent part quality, leading to more efficient production processes in a CNC machining parts factory.

Disclaimer

The content appearing on this webpage is for informational purposes only. LongSheng makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LongSheng’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LongSheng

This article was written by various LongSheng contributors. LongSheng is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.