CNC machines have revolutionized the manufacturing industry by providing precision, accuracy and speed in manufacturing processes. One of the key components that help control the operations of CNC machines is the M code.

What is M Code?

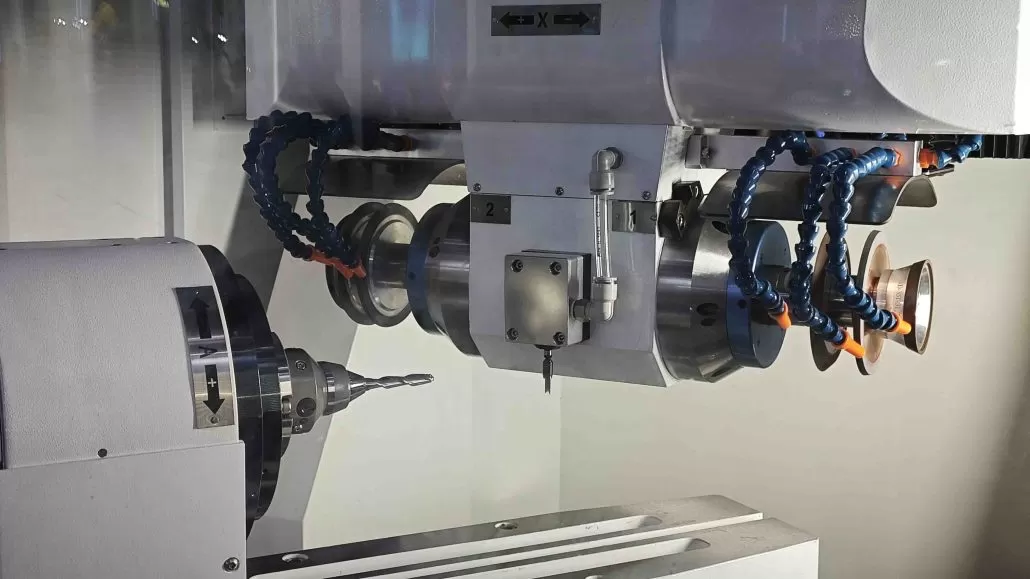

M code is a machine code that controls the CNC machine’s auxiliary functions, such as coolant, spindle speed, and tool changes. It is a function code that tells the CNC machine what action to take. M code commands are executed by the CNC machine’s controller, which interprets the code and sends the appropriate signals to the machine’s hardware components.

M code commands are represented by a letter followed by a number. For example, M03 is a command that tells the machine to start the spindle clockwise, while M08 is a command that turns on the coolant.

How Does M Code Work?

M code is executed in the same way as G code. The CNC machine’s controller reads the M code command and executes the corresponding action. The controller then waits for the next command to be executed. M code commands can be used in conjunction with G code commands to create complex machining operations.

Importance of M Code

M code is essential in CNC machines as it controls the auxiliary functions that enable the machine to perform different operations. For example, without the M code, the CNC machine would not be able to turn on or off the coolant, adjust the spindle speed or change the tool during the machining process.

In addition, M code commands can be used to optimize the machining process by controlling the auxiliary functions based on specific parameters. For instance, a CNC machine can be programmed to turn on the coolant when the temperature of the workpiece reaches a certain level.

M code is also useful in automating the manufacturing process. By using M code commands, CNC machines can be programmed to perform complex operations, resulting in increased productivity, accuracy, and precision in manufacturing processes. This is particularly important in industries that require high precision and accuracy, such as aerospace and medical device manufacturing.

Moreover, the use of M code commands allows for greater flexibility in CNC parts machining. Different operations can be programmed by using different M code commands, allowing for a wide range of manufacturing processes to be performed. This makes CNC machines more versatile and efficient, reducing the need for manual intervention and increasing the speed of manufacturing processes.

Conclusion

In conclusion, M code is a critical component of CNC machines that controls the auxiliary functions necessary for the machine to perform different operations. By using M code commands, CNC machines can be programmed to perform complex operations, resulting in increased productivity, accuracy, and precision in manufacturing processes. Understanding how M code works is essential for CNC machine operators and programmers to create efficient and effective machining processes.