Metal stamping forming is a technique used in metalworking to create durable and precise metal parts for a wide range of industrial applications. If you’re looking for a manufacturing process that can offer both high production speed and accuracy, metal stamping forming is an excellent choice.

In this blog post, we’ll provide a comprehensive overview of metal stamping forming, including the techniques, tools, and benefits associated with it. By the end of this article, you’ll have a clear understanding of what metal stamping forming is and how it can benefit your business.

Metal Stamping Forming Introduction

Metal stamping forming is a metalworking technique that involves creating metal parts from sheet metal using stamping and bending tools. This technique is widely used in the automotive, aerospace, electronics, and consumer goods industries to produce metal parts at high volumes with high precision and repeatability.

What is Metal Stamping Forming?

Metal stamping forming is a manufacturing process that involves bending, punching, and forming metal sheets and plates into various shapes and sizes. The process is achieved through the use of a stamping press, which applies pressure onto the metal sheet to mold it into the desired shape. The process can also involve the use of dies, which are specialized tools used to cut, form and shape metal parts.

Stamping Technique

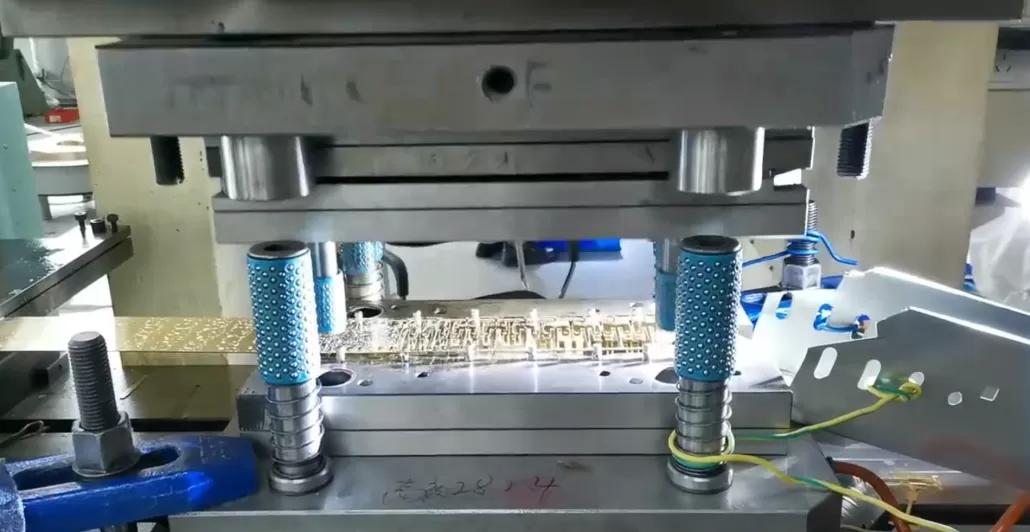

The stamping technique used in metal stamping forming involves applying pressure to a sheet of metal using a stamping press. A stamping press is a machine that applies a force onto a metal sheet to shape it into the desired form.

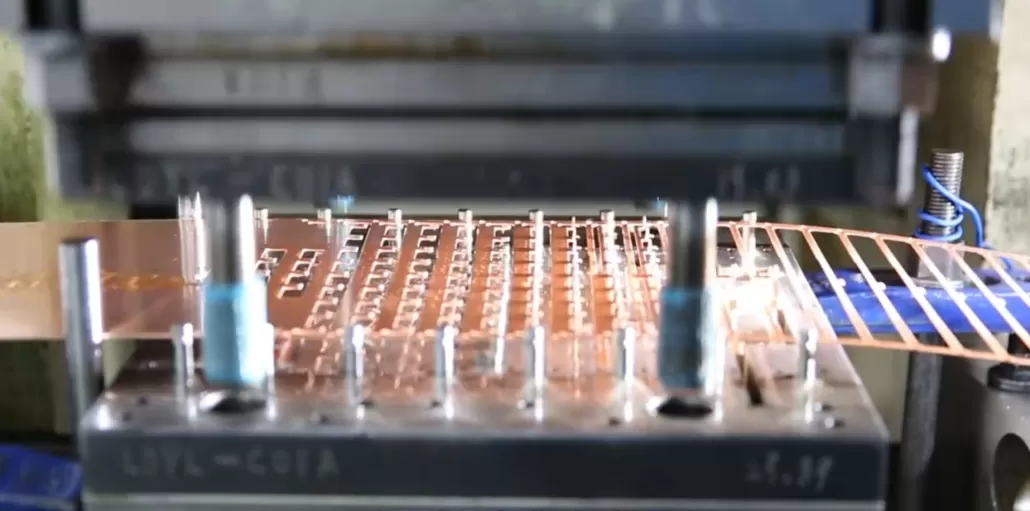

There are two types of stamping techniques: progressive and transfer. Progressive stamping involves sequentially feeding a metal strip into a stamping press to create a series of parts, while transfer stamping involves transferring a partially formed part from one station to another to complete the forming process.

The Advantages of Metal Stamping Forming

Metal stamping forming offers numerous advantages over other methods of metalworking, such as casting or forging. Firstly, it’s a cost-effective method of producing metal components since it allows manufacturers to produce parts in large quantities at a lower cost per unit. As a result, the process is often used for mass production, where consistent quality and low cost are essential.

Secondly, metal stamping forming offers a high degree of precision, which results in high-quality finished products. The process allows for the creation of complex shapes and designs while maintaining accuracy and consistency in both size and shape. This makes it ideal for producing components for complex machinery or equipment, where parts must fit together precisely to function correctly.

Thirdly, metal stamping forming is an efficient process that can be used to produce components and parts quickly. It’s a highly automated process that involves minimal manual labor, which reduces the chances of errors and injuries. This, in turn, results in a faster turnaround time, ensuring that manufacturers can meet their clients’ demands in a timely manner.

The Metal Stamping Forming Process

The metal stamping forming process involves several steps, which include designing, tooling, stamping, and finishing. Here’s a brief overview of each stage:

Designing: This stage involves creating a design for the metal component or part, which outlines its size, shape, and any other necessary specifications.

Tooling: This involves creating a tool, which is used to shape the metal sheets into the desired form or size. The tool can be made from various materials, including steel or carbide.

Stamping: This is the actual metalworking stage where the metal sheets are placed into the press machine, which uses the tool to shape and cut the metal into the desired shape.

Finishing: Once the metal component or part has been shaped, it’s finished to ensure that it meets the necessary standards. The finishing process can include polishing, painting, or coating the metal to protect it from corrosion.

Applications of Metal Stamping Forming

Metal stamping forming is used in various industries, including:

- Automotive: Metal stamping forming is used in the automotive industry to manufacture various parts, such as car body panels, hoods, and doors.

- Aerospace: The aerospace industry uses metal stamping forming to produce parts for aircraft, spacecraft, and satellites.

- Electronics: Metal stamping forming is used in the electronics industry to manufacture small metal parts, such as connectors, springs, and contacts.

- Medical: In the medical industry, metal stamping forming is used to produce surgical instruments and medical devices.

Tools Used in Metal Stamping Forming

The tools used in metal stamping forming include dies, punches, and presses. Dies are metal blocks that are used to shape metal sheets into the desired form, while punches are used to create holes or other features on the metal sheet.

Presses are the machines used in metal stamping forming to apply pressure to the dies and punches, shaping the metal sheets. The choice of the press and the tooling depends on the complexity of the part, the desired output volume, and the type of material being used.

Metal stamping forming is a versatile and efficient manufacturing process that can be used to produce various metal products for different industries. With the tools and techniques available, this process provides high precision, faster production speeds, cost-effectiveness, and customization options to manufacturers.

Metal stamping forming is a versatile and cost-effective metal forming process that offers numerous benefits to manufacturers in various industries. Whether you’re looking to manufacture simple brackets or complex components, metal stamping forming is an excellent option to consider.

If you’re interested in learning more about metal stamping forming services, don’t hesitate to contact us. We are experts in metal stamping forming and can help you manufacture high-quality metal parts to your exact specifications.