An essential technique in the fabrication of plastic parts is vacuum casting. Recognized for its effectiveness and rate, vacuum casting stands apart as a premier method for creating tiny sets of polyurethane items. This process helps produce initial examples of an item, permitting manufacturers to perform market tests before significant manufacturing.

This post intends to shed light on vacuum cleaner casting, an essential process in plastic molding that values interest. We will look into the complexities of the vacuum casting process, including the detailed treatment, the products used, and its extensive range of applications. By understanding the specifics of vacuum casting, stakeholders can much better value its importance in developing and testing new products, ensuring that innovative concepts are possible and market-ready.

What’s Vacuum Casting?

Vacuum casting is a soft tooling strategy using soft silicone mold and mildew to cast polyurethane plastics and elastomers. That’s how it gets the names: silicone spreading and urethane spreading. The spreading occurs in a vacuum cleaner chamber, removing the threat of air bubbles within the actors and making end products precise and remarkable.

Compared to traditional spreading, where metal mold and mildew are long-term, costly, and require time to create, silicone mold-making is quicker. The lead time is around 15 days; a silicone mold and mildew can make up to 25 parts. This makes it among the most recommended techniques for quick prototyping.

The Vacuum Casting Process: A Step-by-Step Overview

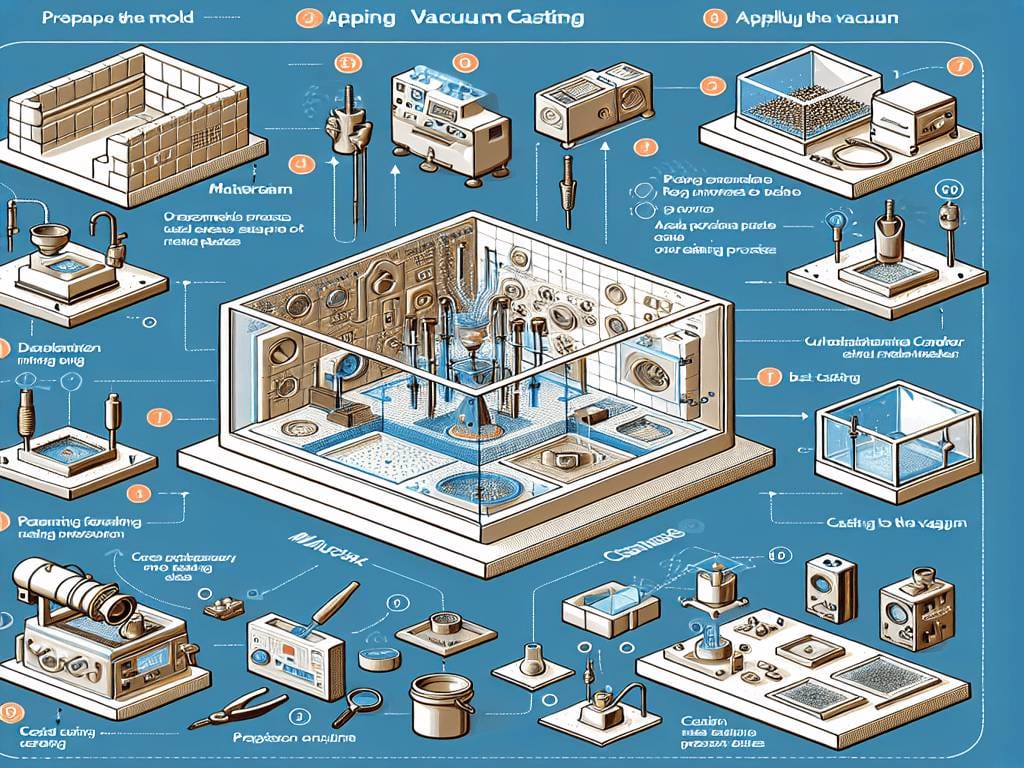

The crucial element of vacuum cleaner casting is the silicone mold and mildew. Nevertheless, some preliminary and post-molding steps are associated with making and using silicone mold and mildew.

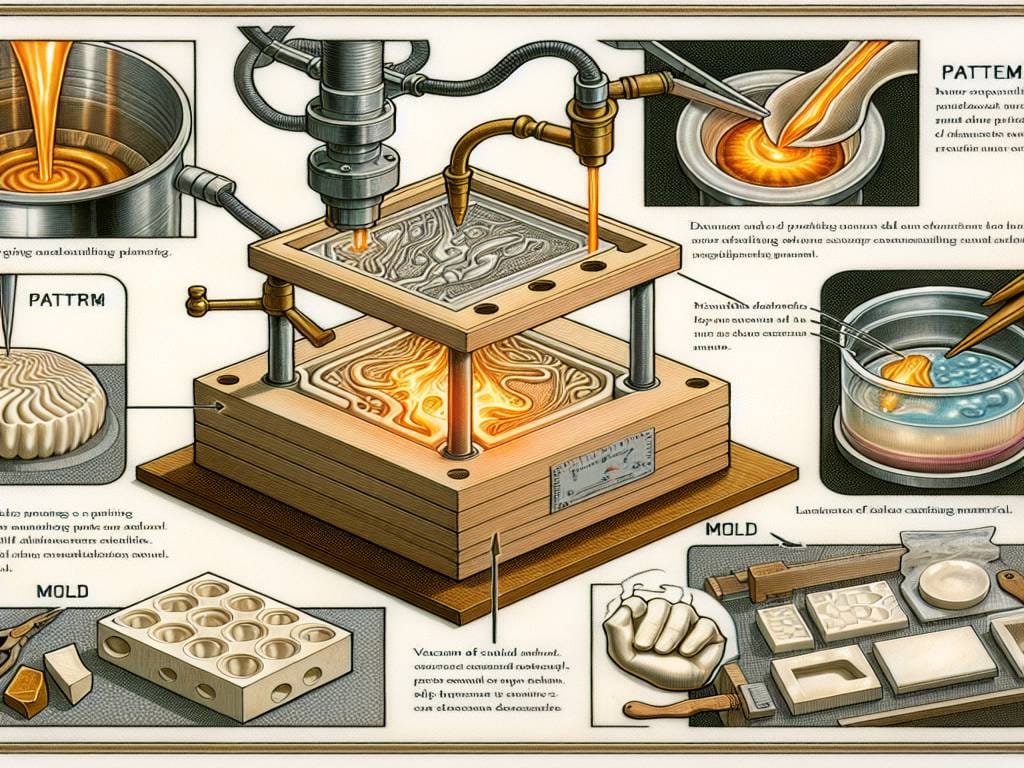

Step 1: Creating the Master Design

First, prepare a master mold to make that silicone mold and mildew. It can be 3D-designed on any CAD software, like SolidWorks, CATIA, or AutoCAD. CNC machining or 3D Printing prevails with choices to bring the mold to life. (Undergo the next area for mold layout pointers.).

The precision of the vacuum cleaner actors’ parts largely depends on the master mold, so it needs to be as specific as feasible. For that, surface sprucing up or grinding is an option.

Step 2: Making the Silicone Mold.

After finishing the master mold, proceed to cast a soft silicone mold. Location the master mold and mildew in a casting box and put liquid silicone. For curing, place the setup in a preheated oven at 40 ℃. It might take 10 to 16 hours for silicone to establish and strengthen.

Eliminate the silicone mold very carefully with a blade. You might use a mold and mildew release representative if you have a problem removing the mold.

Action 3: Casting the Components Under Vacuum Cleaner.

The last step is casting the polyurethane in the silicone mold and mildew. If you’re using a mix of materials, mix them initially. Include shade pigments currently if you desire any shades. Then, get the air out of the mold and mildew to develop a vacuum and pour the material in. This vacuum cleaner action is essential because it stops air bubbles from creating and ensures that the resin covers every part of the mold and mildew.

Materials Used in Vacuum Casting.

The silicone casting procedure broadly matches polyurethane resins and elastomers. Some usual material choices are:

ABS-Like Materials.

Abdominal muscle material is similar to ABS thermoplastic; it’s tough, dimensionally steady, and impact-resistant. Among these materials, ABS-like UP4280 stands out for its heat resistance and high Strength, making it a preferred strength for prototype production. In addition, the PX250 material offers high-effect stamina and UV resistance, high qualities that are perfect for creating things like safety helmets. PX100 provides an additional viable choice for fast prototyping, ensuring a suitable ABS-like material for various applications. This organized approach highlights the advantages and applications of each ABS-like resin, keeping sensible uniformity in content.

Glass-Filled Nylon-Like.

Glass-filled nylon-like material substantially boosts the efficiency of items made via vacuum casting. Including glass fibers right into the nylon matrix substantially enhances the product’s tensile toughness and rigidity. This support enables it to handle higher mechanical loads and tensions, making it a perfect choice for applications that require sturdiness and strength structure makes sure that elements made from Glass-Filled Nylon-Like products are not just more robust but likewise extra efficient in enduring strenuous use.

Elastomeric TPE-Like.

Thermoplastic elastomers such as rubber are likewise perfect for molding. UP8400 is a rubber-like elastomer with a black or white look that moves significantly and has high elongation. It’s used for making gaskets, seals, and handgrips. T0387 is an example of a clear rubber-like product, which is maximized for vacuum casting.

PC-Like.

It’s a straightforward, lightweight, and high-impact product that’s very easy to device. Two PC-like materials, PX510 and UP6160, prevail for vacuum cleaner spreading. They master applications calling for toughness and aesthetic quality, using the convenience of machining and the ability to generate exact, in-depth parts. These materials are suitable for creating components where toughness and aesthetic appeal are vital, making them essential in vacuum casting.

Clear Resins.

Clear resins like PMMA/Acrylic are warm and shatter-resistant with tool stamina. They’re terrific alternatives for casting transparent spreadings and panels. X522HT is an example of a transparent plastic resin that can be used in silicone molding.

High-Impact Resins.

High-impact materials such as UP5690, which looks like polypropylene (PP), and PU8098, comparable to polycarbonate (COMPUTER), are created to replicate the preferable residential properties of their counterparts. These materials flaunt remarkable influence, strengthStrengthsistance to chemicals, providing them excellent for applications subjected to high loads. Their toughness and resilience make UP5690 and PU8098 necessary for creating components that demand resilience and reliability under tension.

| Material | Variations | Characteristics | Hardness |

| ABS-Like | UP4280, PX100, PX250 | Heat and impact-resistant | D78-82 |

| Glass Filled Nylon | — | High StrengthStrengthty | D58 – 75 |

| TStrength | UP8400, T087 | High elongation | D60-80 |

| PC-Like | PX510, UP6160 | Lightweight, clear, high-impact | D82-86 |

| Clear Resins | X522HT, PMMA | High Transparency | D87 |

| High Impact | UP5690, PU8098 | High Impact Strength | D8575-86 |

Design Guidelines for Vacuum Casting

These standards will assist you in designing accurate vacuum cleaner spreading items and critically readjusting information during the layout phase.

Tolerances.

Creating with resistance in mind guarantees your components fit together and fulfill the desired specs. There’s a shrinking of 0.15% in silicone mold and mildew casting. Therefore, the design must be made to adhere to that.

Wall surface Thickness.

With vacuum cleaner spreading, there’s freedom to include varying wall densities within the same part. Nevertheless, for ideal outcomes, it’s best to preserve consistency and keep wall surface thickness at a minimum of 1.5 mm to ensure structural stability.

Ribs.

Adding ribs enhances stamina and minimizes bending, especially in significant-level locations. Its density must be less than the nearby wall surface density to prevent shrinking and sinking. Preferably, rib thickness should be less than 60% of the small wall surface density.

Employers.

When creating real estate or cases, managers are familiar. They add toughness at attachment points. They need to have a minimum diameter height of 1mm. In addition, to lessen the risk of sinking, their wall thickness did not exceed 60% of the minor component density.

Undercuts.

Unlike in processes that need complex tooling, damages in vacuum casting do not demand making use of inserts and can be created freely.

Embossed Details.

For text and logo designs that are embossed (increased) or debossed (recessed), maintain a minimal depth or height of 1mm and a minimum size of 1mm to make sure that these details show up and are crisp. Additionally, keep a 1mm gap between personalities to improve readability.

| Design Element | Detail |

| Tolerance | +-0.05mm |

| Min. Wall Thickness | 1.5 – 2.5 mm |

| Bosses | Height: 1mmDiameter: 1mm |

| Ribs | 60% of wall thickness |

| Embossed Details | Min. Width 1mmMin Depth. 1mm |

| Quantities | 20 – 25 per mold |

| Lead Time | 15 to 20 days |

Applications of Vacuum Casting in Various Industries

Here’s a glimpse of a wide range of industrial applications where the polyurethane casting technique is used:

| Industry | Applications |

| Automotive Industry | Prototype parts: dashboards, door handles, Functional components: light covers, air vents |

| Consumer Electronics | Enclosures for devices: smartphones, laptops, Prototypes for wearable tech, Buttons, and switches |

| Medical and Healthcare | Medical device prototypes: enclosures, components, Custom orthopedic devices, Equipment casings |

| Aerospace Industry | Prototype components: interior cabin parts, Air ducts, and vents. Non-structural parts: covers, enclosures |

| Food and Beverage | Packaging prototypes |

Advantages and Limitations of Vacuum Casting

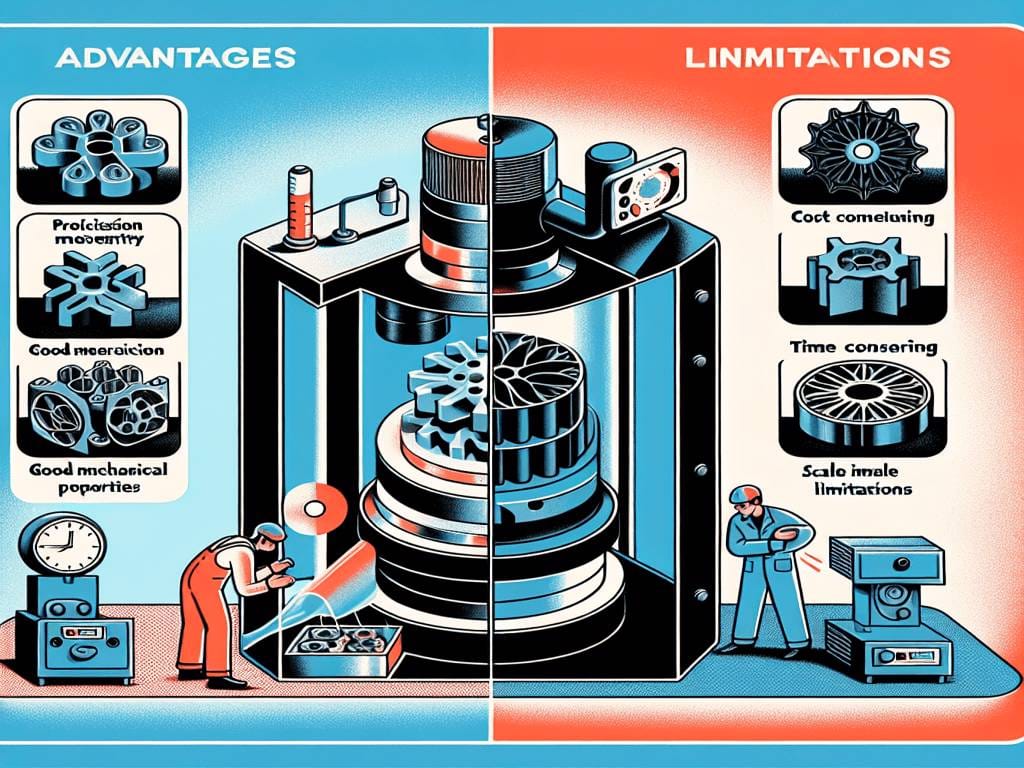

To analyze if the vacuum cleaner spreading process suits your preferred applications, experience these benefits and restrictions.

Benefits.

Design Adaptability: The procedure suits a variety of layout components, from intricate information like ribs, undercuts, and embossed logo designs to complicated design geometries. It’s likewise cost-efficient to make layout changes in soft silicone, which will be thrown out after a couple of usages.

Low-Cost Tooling: The silicone mold and mildew, the critical tools of the process, are much more affordable to build than metallic molds. Silicone mold and mildew are prepared in a couple of hundred bucks, whereas molds for injection molding or steel casting can cost thousands.

Premium Surfaces: Whether the demand is for glossy, matte, or distinctive surfaces, the casting procedure can provide results that satisfy or exceed expectations. One can blend materials, add pigments, and get the desired surface coating and quality.

Quick Turn-around: The only time-tasking aspect is the master pattern style. However, silicone mold preparation takes hours. The preparation for the whole procedure is up to 15 days from start to finish. Meanwhile, a couple of other casting processes take weeks.

Limitations.

Material Restrictions: The silicone molding process works best with polyurethane materials and elastomers, but it’s not appropriate for molding complex commercial products, for example, steels. For steel vacuum casting, there’s a customized comparable procedure called vacuum cleaner die or vacuum cleaner financial investment spreading.

Dimension Constraints: Silicone mold has some size constraints. Mainly, it permits mold and mildew somewhere between 500 to 900mm.

The Longevity of Silicone Molds: These mold and mildew have a restricted lifespan. They can create 20 to 25 top-notch parts before destruction in precision and information happens.

Vacuum casting vs. Other Production Processes.

Ultimately, it allows contrasting vacuum casting with relatively similar molding processes.

Vacuum Cleaner Casting vs Vacuum Forming.

Suppliers pour liquid materials into a silicone mold under a vacuum cleaner to produce high-quality components without air bubbles in vacuum cleaner casting. This method matches prototypes, or small to medium manufacturing runs are ideal.

On the other hand, vacuum forming entails heating a sheet of plastic until it’s flexible and then using vacuum cleaner pressure to create it over a mold. This process is best for more extensive and thinner things like packaging and item real estate.

Vacuum Cleaner Spreading vs Centrifugal Spreading.

Centrifugal casting mainly molds cylindrical parts such as pipelines, bushings, and rings by pouring liquified metal into a revolving mold and mildew. The centrifugal force, after that, evenly distributes the material along the sides, producing a hollow round item. On the other hand, the vacuum cleaner casting technique entails pouring molten polyurethane material into a fixed silicone mold.

Compared to vacuum casting, centrifugal spreading is a better fit for steels and leads to parts with superior mechanical residential properties. Nevertheless, vacuum cleaner spreading provides much more versatility in layout and product choice for non-metallic components, which makes it appropriate for models and non-structural parts.

Vacuum Cleaner Casting vs Injection Molding.

Shot molding is a much more specific advanced variation of silicone vacuum casting. Injection molding pressures liquified material into a steel mold under high pressure to eliminate limited tolerance. It’s suitable for high-volume manufacturing, but the initial prices for tooling are considerably greater and take longer to create than silicone molds used in vacuum cleaner casting.

Meanwhile, vacuum cleaner casting makes use of a silicone mold for casting. It offers flexibility in design adjustments with reduced advance costs for mold production.

Vacuum Casting vs 3D Printing.

3D Printing is an additive production procedure that builds printing by printing digital documents. That indicates it permits any intricate and complicated geometries one can digitally develop. It’s highly versatile and can promptly produce parts, but making several copies takes time.

Vacuum Casting does take longer as it calls for a premium master model (often produced by 3D Printing or CNC machining). However, as soon as mold and mildew are made, it’s quicker to print multiple copies of a part with regular material residential properties and surface finishes.

Is Vacuum Cleaner Casting Expensive?

If we contrast the vacuum casting process with two comparable application procedures, for example, shot molding or 3D molding, it’s much less expensive. Shot mold and mildew are metallic and cost more than silicone and master mold and mildewsws. Second, injection molding machines are costly compared to easy vacuum molding machines. Lastly, materials costs are likewise much less than other procedures.

Choosing the Right Vacuum Casting Service.

Vacuum casting is a requirement of every market- automobile, product packaging, medical, or aerospace. It is likewise excellent for making a range of prototypes that, if produced in-house, can considerably inflate prices.

Suppose your task remains in the pipeline, and you’re eager to see your brand-new product principle emerge with precision and fidelity. In that case, Fast Direct is your premier option for vacuum cleaner spreading solutions. We focus on crafting exact models at a fraction of the typical expense and time.

Our offerings fit a diverse range of demands, whether you’re aiming to prototype a revolutionary layout or perform market tests with a limited set of items.

LongSheng holds ISO 9001:2015 and ISO 13485 accreditations. This ensures that every product we supply satisfies the highest standards of top quality. Our engineering team promotes you from the first design to the advancement of the final product.

Please take the following step with LongSheng: Allow us to bring your concepts to life with unequaled precision and effectiveness!