As a traditional metal processing technology, manual milling still has its unique value in some fields, but it also has a series of obvious shortcomings in practical applications. This article will discuss the main drawbacks of manual milling in detail for the readers’ reference. Gain a fuller understanding of its limitations and possible challenges.

What is a Manual milling?

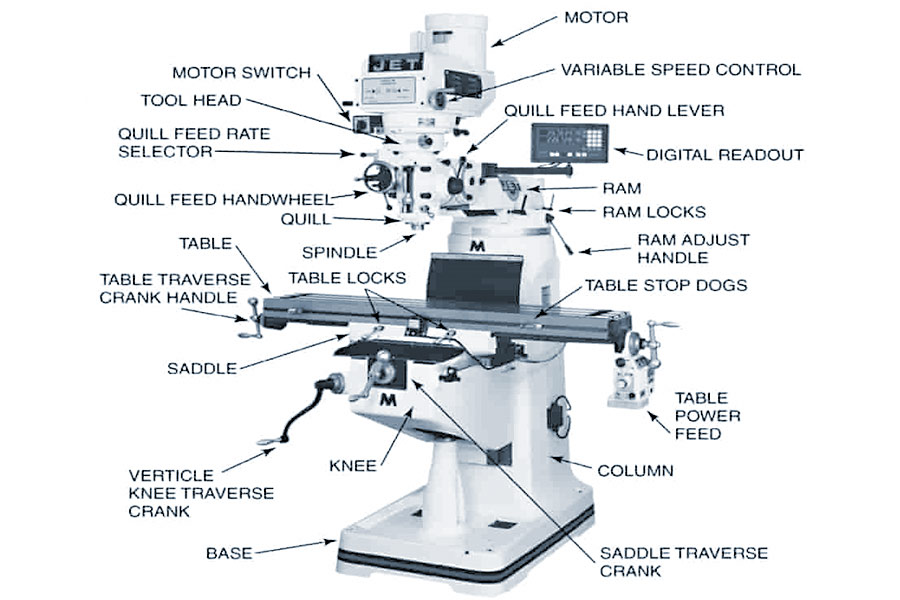

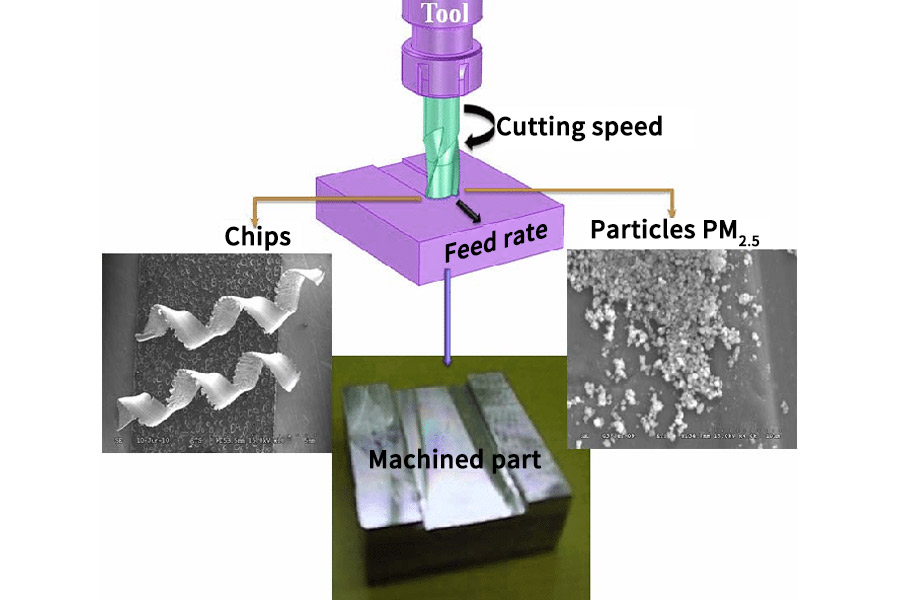

“Milling” is a cutting process used in the engineering industry. The tool rotates to remove material from the workpiece and has multiple cutting points on the tool. Manual milling is a traditional metal cutting technology that relies on the operator’s manual operation to drive a milling machine or handheld milling tool to remove excess material from the workpiece with a rotating cutting tool to obtain the desired shape and size. Manual milling produces a vertical and upright cutting motion. Cutting occurs at the periphery of the tool, and when cutting begins, edges called teeth are cut repeatedly, creating chips from the workpiece.

The entire milling process removes material through individual tiny cuts. Rotating tools operate at high speeds, making the process fast, but the speed depends on the material used. There are many different types of tools for various machining processes, for example: end mills have a cutting surface across them, and some tools can have extended cutting surfaces on the sides.

What are the disadvantages of manual milling?

- Skilled Labor Required: Effective operation of a manual milling machine requires a high level of skill and experience. This makes finding qualified operators and ensuring consistent quality a challenge.

- Time consuming: Manual milling is significantly slower compared to CNC machines. Milling complex or high-volume parts is labor intensive.

- Limited Accuracy: It is difficult to achieve precise dimensions and tolerances with a manual mill, especially with complex shapes. This can lead to higher scrap rates and the need for rework.

- Complexity Limitations: Manual milling machines struggle with complex designs and require more operator intervention to achieve moderately complex shapes. This makes them unsuitable for applications requiring highly detailed components.

What is the difference between manual milling and CNC milling?

- Control: Manual milling relies on the operator’s skill and dexterity to guide the cutting tool. CNC milling, on the other hand, uses pre-programmed instructions to automate the entire process.

- Accuracy: Human error affects the accuracy of manual milling. CNC milling, on the other hand, can consistently produce high-precision parts due to its computer-controlled movements.

- Production speed: Manual milling is slow, especially for complex designs. CNC milling excels in high-volume production, replicating parts quickly and accurately.

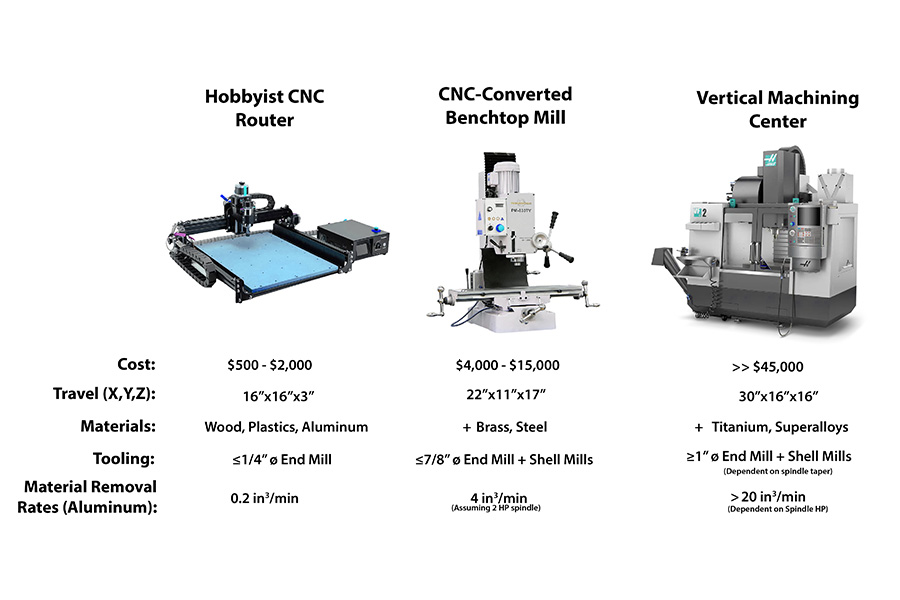

- Cost: Manual mills are generally less expensive than CNC mills. However, the efficiency of CNC milling can save time and labor costs in the long run on large projects.

- Complexity: Simple design ideal for manual milling. Complex parts with tight tolerances are better suited to the superior precision of CNC milling.

- Both manual and CNC milling have their uses. Choosing the right method depends on the complexity of the project, production volume and the level of accuracy required.

Factors to consider when choosing the right milling method

Machining accuracy and tolerance requirements

- CNC milling: Due to computer control, CNC milling can provide higher accuracy and tolerance control, usually between +/- 2 wires to +/- 10 wires, and some machine tools can even achieve up to +/- 1 wire or more High tolerances.

- Manual milling: Although it can also achieve a certain degree of accuracy, it is usually affected by the worker’s skills and experience, and the accuracy and tolerance may not be as stable as CNC milling.

Processing efficiency and output

- CNC milling: It has a high degree of automation, can work continuously for a long time, is suitable for mass production, and has high processing efficiency.

- Manual milling: relies on worker operation and has relatively low processing efficiency. It is suitable for processing small batches or specially customized products.

Processing complexity and variety

- CNC milling: Suitable for machining parts of complex shapes and designs, such as those found in aerospace, medical equipment, and robotics.

- Manual milling: Although complex shapes can also be machined, the processing complexity and diversity are relatively limited.

cost and investment

- CNC milling: The initial investment cost of CNC milling is relatively high, involving many aspects such as machine tools, control systems and programming software, but due to its high efficiency, high precision and low error rate, its long-term operating costs may be relatively low.

- Manual milling: The initial investment cost of manual milling is relatively low, but its long-term operating costs are likely to rise due to a variety of factors such as worker wages, skills training and operator errors.

Personnel needs and technical requirements

- CNC milling: CNC milling requires specialized programming and operators, but this also reduces reliance on experienced labor.

- Manual milling: Although manual milling has higher requirements for workers’ skills and experience, it can provide them with more employment opportunities.

Production flexibility and customization needs

- CNC milling: CNC milling technology can quickly adjust programs to meet various processing requirements and is very suitable for personalized production.

- Manual Milling: Although manual milling can meet specific custom requirements, it may not be as fast and adaptable as CNC milling.

Maintenance and care

- CNC milling: Regular maintenance and upkeep is required to ensure the machine tool and control system are functioning properly.

- Manual Milling: Also requires care and maintenance, but is relatively simple.

What are the main functions of manual milling?

Manual milling machines are mainly used to finish the workpiece surface into flat surfaces, inclined surfaces, grooves, gears and other shapes. Due to the high rotation speed and wide processing range of the milling cutter, it is suitable for various processing methods such as milling, drilling, boring, milling and cutting.

What are the application fields of manual milling?

- Automotive field: In the automotive manufacturing industry, manual milling is often used to process various metal parts, such as engine parts, chassis parts, etc.

- Mold field: Mold manufacturing requires high-precision and complex shape processing. Manual milling can meet these needs and process various mold parts.

- Mechanical field: In machinery manufacturing, manual milling is used to process various mechanical parts, such as shafts, sleeves, gears, etc.

- Other fields: In addition, manual milling is also widely used in aviation, shipbuilding, petrochemical and other fields.

What types of manual milling are there?

| Type of manual milling | Narrate |

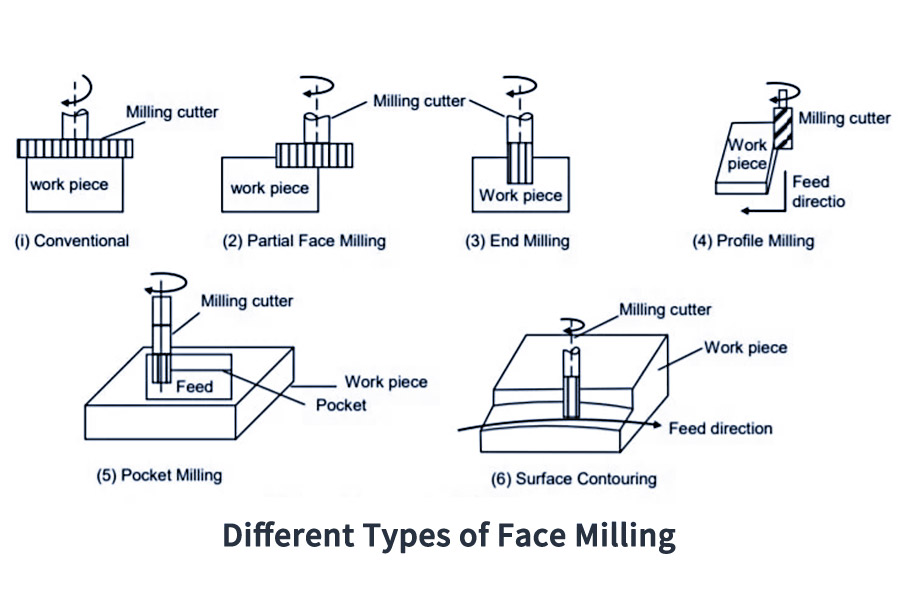

| Face milling | a plane processing method, mainly used to process shapes such as planes, slots, and holes. It is suitable for large-area surface processing and has high processing efficiency. |

| End milling | a method of processing the end face of a workpiece, mainly used to process shapes such as flanges and steps. It can accurately process the end face of the workpiece to ensure the dimensional accuracy of the workpiece. |

| Slot milling | a method of processing slots, mainly used to process shapes such as slots and keyways. Slot milling can quickly remove material to create a variety of slot structures. |

| Contour milling | a processing method for milling workpiece contours, which is mainly used to process irregular contours, curved surfaces and other shapes. It requires a high technical level and operating experience to be able to process complex workpiece shapes. |

What are the precautions for manual milling?

Safe operation

Before operation, ensure that all parts of the machine tool and protective devices are in good working order. Wear appropriate protective equipment, such as hard hats, protective glasses, protective clothing, etc, to avoid damage to eyes and skin caused by splashing chips and coolant. When the machine tool is running, it is not allowed to adjust, measure the workpiece, or change the lubrication method to prevent injuries caused by touching the tool with your hands. It is forbidden to operate the machine tool while wearing gloves to prevent the gloves from getting caught between the rotating tool and the workpiece.

Workpiece installation and fixation

The workpiece to be processed should be firmly mounted on the fixture or workbench to ensure that the workpiece will not move or become loose due to cutting forces. When installing the workpiece, you should carefully check whether there are cracks, burrs and other defects on the surface of the workpiece to avoid damage to the tool or scrapping of the workpiece during the processing.

Tool selection and installation

Select the appropriate milling cutter according to the properties of the processed material and processing requirements to ensure that the geometric parameters and cutting performance of the tool meet the processing requirements. When installing the tool, ensure that the concentricity between the tool and the spindle is good, and the tightening force of the tool should be moderate to avoid damage or falling off of the tool due to excessive tightening or looseness.

Cutting parameter adjustment

Reasonably adjust the cutting parameters according to the hardness, cutting depth, feed rate and other factors of the processed material to ensure a stable and efficient cutting process. Avoid problems such as excessive cutting force, excessive cutting temperature, and increased tool wear caused by improper setting of cutting parameters.

Cutting process monitoring

During the cutting process, you should pay close attention to changes in cutting sound, cutting force, cutting temperature, etc, and detect and deal with abnormal situations in a timely manner.If abnormal cutting sound, excessive cutting force, or excessive cutting temperature are found, the machine should be stopped immediately for inspection, and the fault should be eliminated before continuing processing.

Machine tool maintenance and upkeep

Carry out maintenance work such as cleaning, lubrication and tightening of machine tools regularly to ensure that all parts of the machine tool are in good working condition.

Regularly check the operation of key components such as the electrical system, hydraulic system, and transmission system of the machine tool, and promptly repair or replace any abnormalities found.

Cutting fluid usage

During the cutting process, cutting fluid should be used rationally to reduce cutting temperature, reduce tool wear, and improve processing quality. The type and concentration of cutting fluid should be reasonably selected according to the nature of the material to be processed and the processing requirements to avoid improper use that may lead to cutting fluid contamination or corrosion of the machine tool.

Tips For Choosing A Milling Company

Corporate Expertise And Reputation

The first thing to consider when choosing a milling company is the company’s expertise and reputation. Professional companies like Longsheng can usually offer higher quality services because they have the knowledge and experience of handling a variety of complex milling tasks. Also, the company’s reputation is important because it reflects the quality of their work and customer satisfaction. Longsheng is known for its good reputation and high quality service.

Tools And Tricks

The tools and technologies used by companies are also important considerations. Companies like Longsheng that use the latest tools and technologies can often provide more accurate and efficient milling services. Furthermore, they are more likely to handle a variety of complex milling tasks.

Service And Assistance

Excellent customer service and support are also important factors in choosing a milling company. Companies like Longsheng that provide excellent customer service can ensure that they meet your needs and help with problems. In addition, they also offer personalized solutions to meet your specific needs.

Value And Supply Time

Finally, price and delivery time are also factors to consider. It is best to choose a company that can provide reasonable prices and fast delivery time, such as Longsheng. Remember, however, that quality and service are often important, so don’t make decisions based on price alone.

Summary

Compared with modern processing technologies such as CNC milling, manual milling has obvious limitations in terms of accuracy, efficiency and processing range. But manual milling still maintains its unique status in some areas. For example, manual milling still plays an important role in scenarios such as restoration work, teaching demonstrations, prototyping or custom machining. In addition, for some special materials or complex-shaped workpieces, manual milling may become the only processing method. Therefore, when selecting a processing method, comprehensive considerations need to be made based on specific processing needs and conditions.Visit our Instant Quote Engine to get a free, no-obligation quote in minutes.

Disclaimer

The content appearing on this webpage is for informational purposes only. LongSheng makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LongSheng’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LongSheng

This article was written by various LongSheng contributors. LongSheng is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

FAQs

Are manual grinders still in use?

Manual mills are still in use today and play an important role in specific fields and occasions. Although the development of science and technology and the improvement of automation level have made other equipment such as electric grinders widely used in industrial production, manual grinders have been retained and inherited because of their unique advantages and applicable occasions.

What are the advantages of manual milling?

①Details: Since the hand milling process requires more time and attention, it is more suitable for producing smaller objects and adding fine details. Repair work and fine-tuning defects is much easier with hand milling.②Cheap: The price of manual milling machines is much lower than CNC precision engineering machine tools, so you are more likely to find a local company that has them in stock.③Intuitive: Because manual machines are simple to operate and have been around much longer than CNC machines, manual machine operators are easier to find.④ No programming required: A lot of programming is required to make a CNC machine work properly. Manual machines require no programming; this means you don’t need technical experts on hand to deal with possible program failures.⑤ Faster setup time: Since manual milling does not require any programming, this means that the work can start immediately, thus eliminating an hour or two of pre-programming time, which can save a lot of time in the long run.

How to choose between manual milling and CNC milling?

When deciding whether to choose manual or CNC milling, you need to consider the type of project you are working on. If you are doing high-volume production, CNC milling is a fast and efficient option, but if you are doing low-volume components or repairing/modifying existing parts, then manual milling will give you better results. For added flexibility, it’s best to use a combination of CNC and manual milling during production, so you can work with precision components and parts without restrictions.

How do we differentiate between a manual lathe and a CNC lathe?

The main difference between manual lathes and CNC machining is precision and time consumption. With careful cutting, you can achieve high precision on a manual lathe, while CNC machining provides extremely accurate and precise parts in less time and price. You can operate and perform complex machining with no experience with a CNC lathe, whereas manual lathes require considerable experience to perform machining.

Which is safer, the manufacturing process CNC machining or manual machining?

You have to operate manual machines by touching and handing them. It may be more dangerous to operate manual machines. On the contrary, CNC machines are automatic, and you don’t need to handle them physically. They are far from the workers, and the operating process is completed in a safe room or behind a safe door. So CNC machining proves a safer and more effective method than manual machining.