CNC milling is a manufacturing process that involves the use of computer-controlled machines to remove material from a workpiece. The process offers a wide range of advantages over traditional milling methods, including precision, efficiency, versatility, reduced costs and waste, and automation. we will explore the steps involved in CNC milling in detail.

Step 1: Design the CAD Model

The first step in CNC milling is to design the CAD (computer-aided design) model. This involves creating a 3D model of the part that will be produced. The CAD model is then converted into a CAM (computer-aided manufacturing) model, which is used to program the CNC machine.

Step 2: Program the CNC Machine

Once the CAM model is created, the next step is to program the CNC machine. This involves inputting the instructions for the CNC machine to follow, such as the cutting speed, cutting depth, and cutting path.

Step 3: Set Up the Workpiece and CNC Machine

After the CNC machine is programmed, the workpiece is set up on the machine. This involves attaching the workpiece to the worktable and securing it in place. The CNC machine is also set up, including the cutting tool and the worktable.

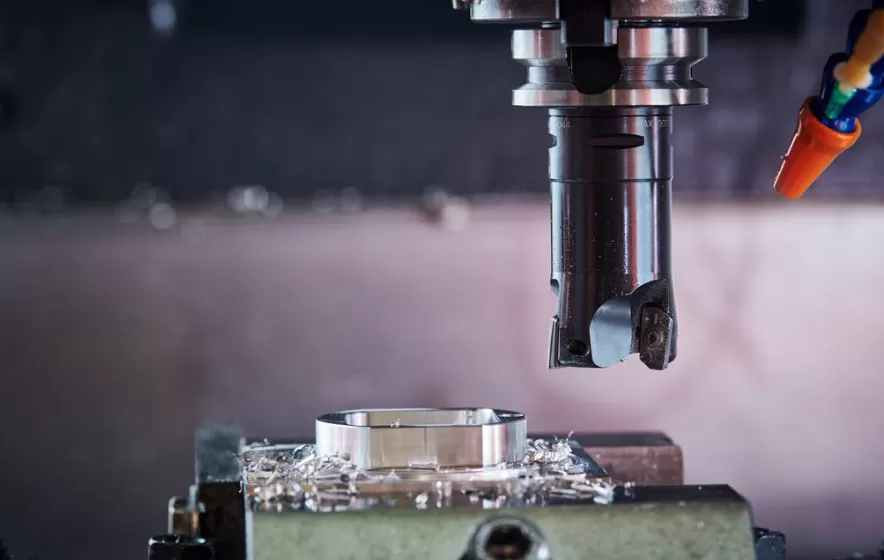

Step 4: Begin the Milling Process

Once the workpiece and CNC machine are set up, the milling process can begin. The CNC machine follows the programmed instructions to remove material from the workpiece. The cutting tool rotates at high speeds and removes material in a precise and controlled manner.

Step 5: Monitor the Milling Process

During the milling process, it is essential to monitor the machine and the workpiece. This ensures that the process is running smoothly and that the part is being produced to the desired specifications. Any issues or errors can be identified and addressed during this step.

Step 6: Complete the Milling Process

Once the milling process is complete, the workpiece is removed from the CNC machine. The part is then inspected to ensure that it meets the desired specifications. Any necessary finishing or post-processing steps are also completed during this step.

Conclusion

CNC milling is a complex manufacturing process that involves multiple steps, including designing the CAD model, programming the CNC machine, setting up the workpiece and machine, beginning the milling process, monitoring the process, and completing the milling process. By understanding the steps involved in CNC milling, manufacturers can ensure that the process runs smoothly and produces high-quality parts.

If you’re interested in learning more about CNC milling or implementing CNC milling in your manufacturing process, be sure to consult with experts in the field to determine the best solutions for your specific needs and requirements.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC machining parts service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items