CNC parts, produced by the extremely exact and customizable Pc Numerical Management (CNC) machining process, are extensively used throughout a number of industries together with aerospace, automotive, telecommunications, medical, and basic manufacturing. The article additional delves into the importance of those parts in every business, highlighting their integral function in manufacturing advanced parts the place precision is paramount. The article additionally gives a step-by-step illustration of the CNC machining process, from the preliminary design stage utilizing CAD software program, by means of to programming with CAM software program, the precise machining process, and eventually, high quality management for making certain consistency and accuracy. This complete information goals to make clear the widespread functions of CNC parts and the intricate process behind their creation.

Makes use of of CNC Parts

CNC parts are integral to a mess of industries as a consequence of their versatility and precision. The functions of CNC parts are numerous and embrace:

-

Structural Parts: These are important for industries that require excessive power and rigidity, similar to aerospace, automotive, and equipment. Examples embrace engine casings, machine beds, instrument housings, precision instrument frames, and architectural structural elements.

-

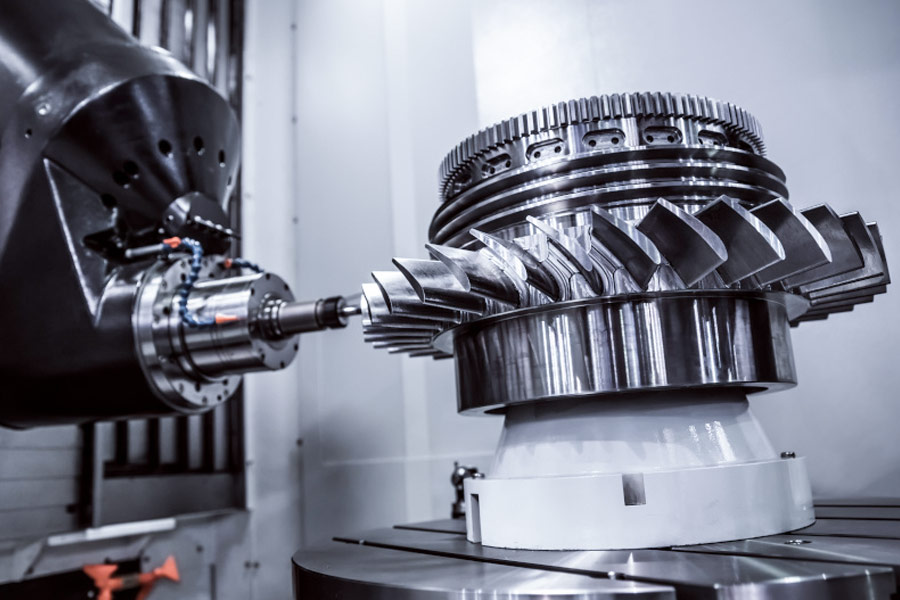

Useful Parts: CNC machining produces high-precision and dependable parts like gears, bearings, screws, cams, blades, valves, and pump our bodies, making certain the graceful operation of mechanical gear’s transmission, sealing, and hydraulic capabilities .

-

Molds: Excessive-precision and high-finish molds for stamping, injection molding, die casting, forging, and rubber molding are created utilizing CNC machining, enhancing the standard and consistency of merchandise .

-

Different Purposes: CNC machining caters to the manufacturing of artworks, crafts, customized parts, medical gadgets, and academic fashions, assembly the calls for for {custom} designs and particular functions .

Machining CNC Parts

The process of CNC machining includes a number of key steps:

-

Superior Pc Software program: CNC machining makes use of state-of-the-art pc software program to information manufacturing instruments similar to milling machines, grinders, lathes, and planers .

-

Aerospace and Automotive Precision: In sectors like aerospace and automotive, parts should function reliably beneath harsh situations, necessitating extraordinarily excessive precision in manufacturing .

-

Medical Purposes: CNC parts are broadly used within the medical business for elements which are essential for the security and success of medical procedures and coverings. This consists of {custom} implants, digital medical gadgets, prototypes, surgical instruments, and parts, in addition to {custom} prosthetics and dental elements .

-

Automotive Customization: The demand for {custom} automotive parts is rising, and CNC machining is a mature methodology for producing these parts as a consequence of its scalability and the flexibility to provide parts shortly, exactly, and precisely .

CNC Machining Strategies

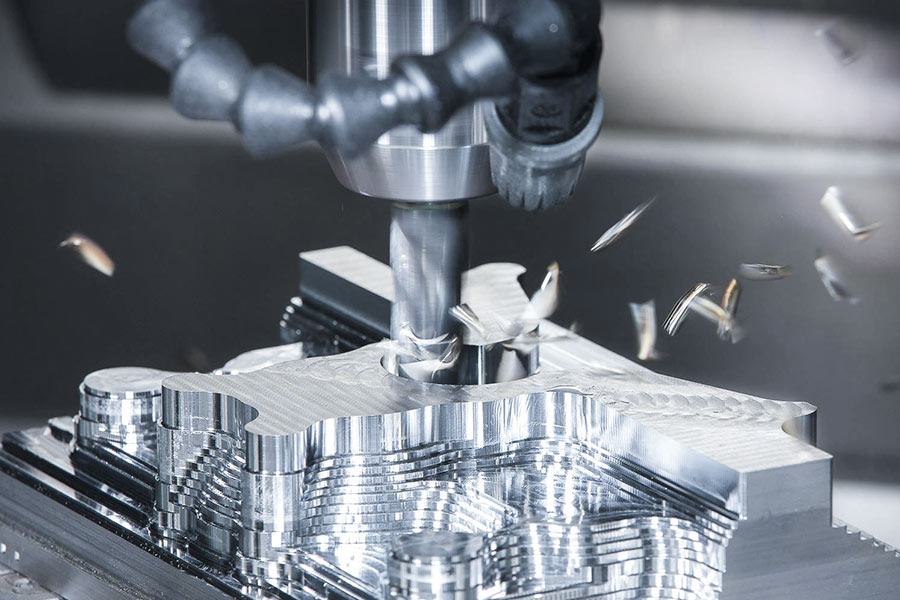

Milling

Milling is a flexible CNC machining process that includes using rotating slicing instruments to take away materials from a workpiece. This methodology is able to creating a wide selection of shapes, slots, holes, and notches, and is appropriate for varied supplies together with metals and plastics. The precision of CNC milling machines permits for the manufacturing of extremely correct and complex parts.

Turning

Turning is a CNC machining process the place the workpiece rotates whereas a slicing software strikes in a linear trend. This methodology is primarily used to create cylindrical parts by eradicating materials from the exterior floor or bore of a workpiece. CNC lathes and turning facilities are designed to carry out turning operations with excessive precision and effectivity.

Drilling

Drilling is a basic CNC machining operation that creates spherical holes in a workpiece. It’s generally used within the manufacturing of varied merchandise the place exact holes are required. CNC drilling machines are geared up with drill bits that may bore holes to precise depths and diameters.

Grinding

Grinding in CNC includes using an abrasive wheel that rotates at excessive speeds to take away materials from the floor of a workpiece. This methodology is used to attain a excessive floor end high quality and to deliver parts inside very tight tolerance limits. CNC grinding machines are used for this process, which is crucial for producing parts that require a excessive stage of precision and smoothness.

Composite Machining Strategies

Along with the fundamental strategies, there are composite CNC machining processes similar to mill-drilling and turn-grinding. These mix totally different machining methods to extend flexibility and effectivity in producing parts that meet particular necessities.

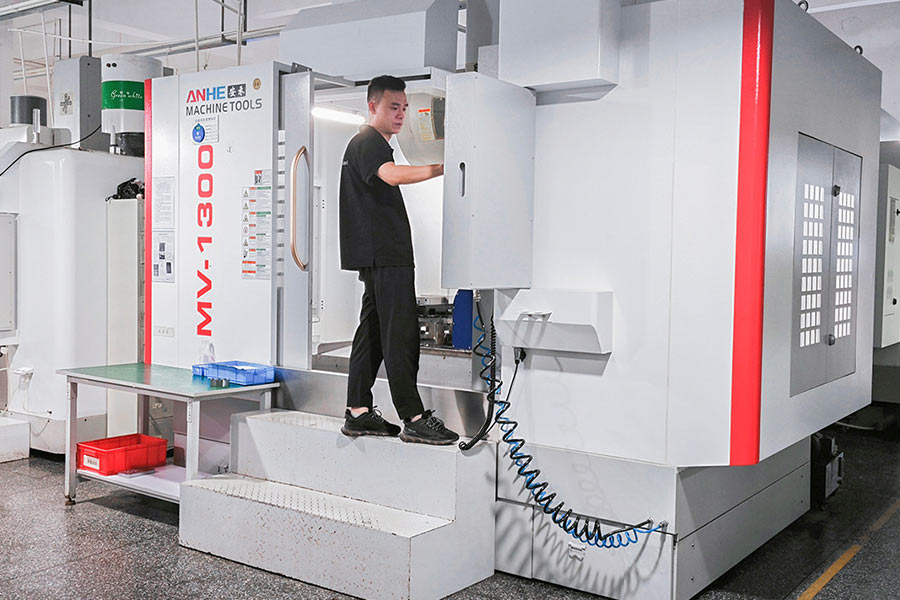

CNC Machining Facilities

CNC machining facilities are superior machines that may carry out a number of forms of machining operations, like milling, turning, drilling, and grinding, in a single setup. This multi-tasking functionality leads to greater productiveness and adaptability within the manufacturing process.

Advantages of CNC Parts Machining

CNC parts machining has quite a few benefits over conventional machining strategies. Listed here are a few of the key benefits:

| Benefit | CNC Parts Machining | Conventional Machining Strategies |

|---|---|---|

| Excessive Precision | CNC machining can obtain extraordinarily excessive precision, with errors sometimes within the micrometer vary. It’s because CNC machines can transfer the slicing software in keeping with a pre-set program, making certain precise dimensions and shapes of parts. | Conventional guide machining strategies usually wrestle to attain this stage of precision, as they depend on the abilities and expertise of the operator. |

| Excessive Flexibility | CNC machining gives excessive flexibility as it may well adapt to numerous part designs just by altering this system. This makes CNC machining ideally suited for the manufacturing of {custom} parts. | Conventional machining strategies sometimes require altering instruments or adjusting machine settings to adapt to totally different part designs, including to manufacturing time and prices. |

| Excessive High quality | CNC machining can produce persistently high-quality parts. Because the machining process is automated, every part is machined in keeping with the identical parameters and requirements, making certain constant high quality. | Conventional guide machining strategies can result in inconsistent high quality as a consequence of operator fatigue or errors. |

| Security | CNC machining is safer because the operator doesn’t must straight work together with the slicing software or workpiece. Furthermore, many CNC machines are geared up with protecting options that may routinely cease the machine in case of a malfunction. | Conventional guide machining strategies might expose operators to extra security dangers as they need to straight function the machines and instruments. |

Software Prospects of CNC Parts Machining

With steady technological developments and price reductions, CNC machining presents huge software prospects throughout varied fields.

Composite Materials Machining

With the growing demand for light-weight and high-performance supplies in industries like aerospace and automotive, CNC machining applied sciences will proceed to enhance to deal with a greater diversity of composite supplies. These composite supplies normally possess wonderful mechanical properties and chemical stability however are difficult to machine. The event of CNC machining applied sciences will make the machining of those composite supplies extra possible, assembly the manufacturing wants for light-weight, high-strength, and high-performance parts.

Additive Manufacturing (3D Printing)

CNC machining and 3D printing applied sciences will complement and merge with one another. Whereas 3D printing can shortly create parts with advanced shapes, its precision and floor smoothness normally cannot match CNC machining. Subsequently, CNC machining can be utilized for subsequent processing and trimming of 3D printed parts, enhancing the precision and floor smoothness of 3D printed elements.

Good Manufacturing

CNC machining will combine into good manufacturing techniques, attaining integration with Pc-Aided Design (CAD) and Pc-Aided Manufacturing (CAM) software program to understand a totally digitalized manufacturing process. It will make the manufacturing process extra automated, enhancing manufacturing effectivity and adaptability, and lowering manufacturing prices. Moreover, by accumulating and analyzing information throughout the machining process, optimization of the manufacturing process will be realized, additional enhancing manufacturing effectivity and product high quality.

Customized Customization

With the growing demand for customized merchandise amongst shoppers, CNC machining will grow to be extra prevalent, able to assembly the wants for small-batch, multi-variety customized customization. CNC machining can shortly transition from design to fabricate with out the necessity for advanced molds and gear, making it extremely appropriate for customized manufacturing. It will present shoppers with extra personalized services, fulfilling their distinctive calls for.

Why select LongSheng to CNC Machining parts?

Selecting LongSheng for CNC parts machining can supply a number of advantages. LongSheng’s CNC machining providers are identified for his or her excessive accuracy, precision, and broad vary of fabric compatibility. The corporate’s superior CNC machines and expert operators can produce parts shortly and effectively, lowering lead instances and prices. Moreover, LongSheng’s dedication to high quality ensures that every one parts meet the very best requirements, making it a dependable alternative for industries that require precision and consistency.ConClusion

CNC parts machining is a vital process in varied industries, together with however not restricted to aerospace, automotive, medical, and telecommunications. This process is used to create a variety of parts with various ranges of complexity, from easy shapes to intricate designs.

CNC machining makes use of computerized controls and machine instruments to take away layers of fabric from a inventory piece, producing a custom-designed part. This process is appropriate for a variety of supplies, together with metals, plastics, wooden, glass, foam, and composites.

The process begins with a design created utilizing Pc-Aided Design (CAD) software program. This design is then translated into manufacturing directives by Pc-Aided Manufacturing (CAM) software program. The CNC machine follows these directives to create the part.

CNC machining gives a number of benefits over conventional manufacturing strategies. For example, it permits for top precision, because the machine can transfer the slicing software in keeping with a pre-set program. This ensures the precise dimensions and shapes of parts, which is especially necessary in industries like aerospace the place parts should meet stringent specs and tolerances.

CNC machining additionally gives excessive flexibility, as it may well adapt to numerous part designs just by altering this system. This makes it ideally suited for the manufacturing of {custom} parts. Moreover, the process is automated, making certain constant high quality and lowering the danger of human error.

By way of particular machining strategies, CNC machining can contain processes similar to milling, turning, drilling, and grinding. For example, CNC grinding machines use a rotating flat abrasive wheel to take away materials from tough workpiece surfaces, making a smooth-finished part.

Trying ahead, CNC machining is anticipated to play an excellent bigger function in varied industries. For instance, will probably be essential within the machining of composite supplies for light-weight and high-performance parts. It is going to additionally complement 3D printing applied sciences, refining and shaping 3D printed parts to reinforce their precision and floor smoothness. Moreover, CNC machining will combine into good manufacturing techniques, attaining a totally digitalized manufacturing process that improves effectivity and reduces prices. Lastly, with the growing demand for customized merchandise, CNC machining will grow to be extra prevalent, assembly the wants for small-batch, multi-variety customized customization.

FAQs

What supplies are appropriate for CNC machining?

CNC machining is appropriate for a wide range of supplies, together with metals, plastics, wooden, glass, foam, and composite supplies. This versatility permits it for use in a variety of functions, able to producing parts from easy shapes to advanced designs.

What data and abilities are required to be taught CNC machining?

Studying CNC machining requires a stable understanding of Pc-Aided Design (CAD) and Pc-Aided Manufacturing (CAM) software program, in addition to data of machining processes and gear operations. Moreover, particular experience in sure CNC machining varieties (similar to milling, turning, drilling, and grinding) is critical.

How to decide on a high-quality CNC machining provider in China?

To pick a high-quality CNC machining provider in China, think about elements similar to the extent of kit sophistication, technological experience, high quality management techniques, lead instances, service ranges, and buyer suggestions. Moreover, for particular business necessities, think about the provider’s expertise and specialization in that specific area.

Supply

13 Parts of CNC Machine + Function & PDF: A Clear Guide

What is CNC Machining? | Definition, Processes, Components & More