In today’s rapidly developing industrial field, CNC machining technology is not only a catalyst for innovation, but also an engine for production efficiency, bringing accurate, efficient and high-quality manufacturing methods to various industries.

So how does CNC machining shape the development trend of the future industry? In this article, we will take an in-depth look at the application of CNC machining in different industries and explore how it has a profound impact in terms of production efficiency, product quality and technological innovation

Application of CNC machining technology in various industries

CNC machining technology has a wide range of applications in different industries, especially recently. With these technologies, manufacturers and product designers in the automotive, aerospace, medical and other industries can prototype or make different products using a variety of materials from plastic to metal. This section provides a detailed overview of the applications of CNC machining technology in some of the above industries.

Automobile manufacturing

In the automotive industry, CNC machining technology has brought many innovations and advantages to manufacturers and designers, from prototype design to component manufacturing, all of which reflect its widespread application. The following will provide a detailed introduction to the different applications of CNC machining technology in the automotive industry.

1.Prototyping and design iteration

Traditional auto parts manufacturing takes a lot of time and resources. However, CNC machining technology accelerates the process of prototyping and design iteration by turning 3D models into actual parts. Manufacturers and designers can use CNC machining to quickly produce 3D prototypes to evaluate their appearance, functionality and adaptability. This allows the design team to identify potential defects or improvement points more quickly and make necessary adjustments before the product goes into production.

2.Parts customization

The automotive industry needs a wide variety of parts, and CNC machining technology makes it easier to manufacture customized parts. Manufacturers can customize the production of specific parts according to different models, models or customer needs. This ability to customize helps meet changing market demands while providing better functional performance and adaptability.

3.Tooling and manufacturing AIDS

The production process of auto parts requires a variety of molds and manufacturing AIDS. CNC machining technology enables manufacturers to customize manufacturing tools, such as jigs, fixtures and molds, to suit specific production processes. This helps increase production efficiency, reduce costs, and ensure precision and consistency of parts.

4.Production of small or special vehicles

Thanks to the flexibility and rapidity of CNC machining technology, manufacturers can now more easily produce small batches or specialty vehicles, such as limited edition cars. This capability becomes critical in the fast car market as it allows manufacturers to introduce new models or special versions more quickly to meet market demand.

5.Material innovation and lightweight

Car manufacturers are increasingly demanding lightweight and fuel efficiency. CNC machining technology makes it easier to manufacture parts using new materials and alloys. For example, manufacturers can replace traditional component materials with lighter, stronger materials, resulting in lighter weight and improved fuel efficiency in vehicles.

6.Rapid prototyping

Rapid prototyping is crucial in the automotive design process. CNC machining technology makes the manufacturing process from digital models to actual parts much faster and more efficient. The design team can quickly prototype various parts for testing, evaluation and modification.

Aerospace industry

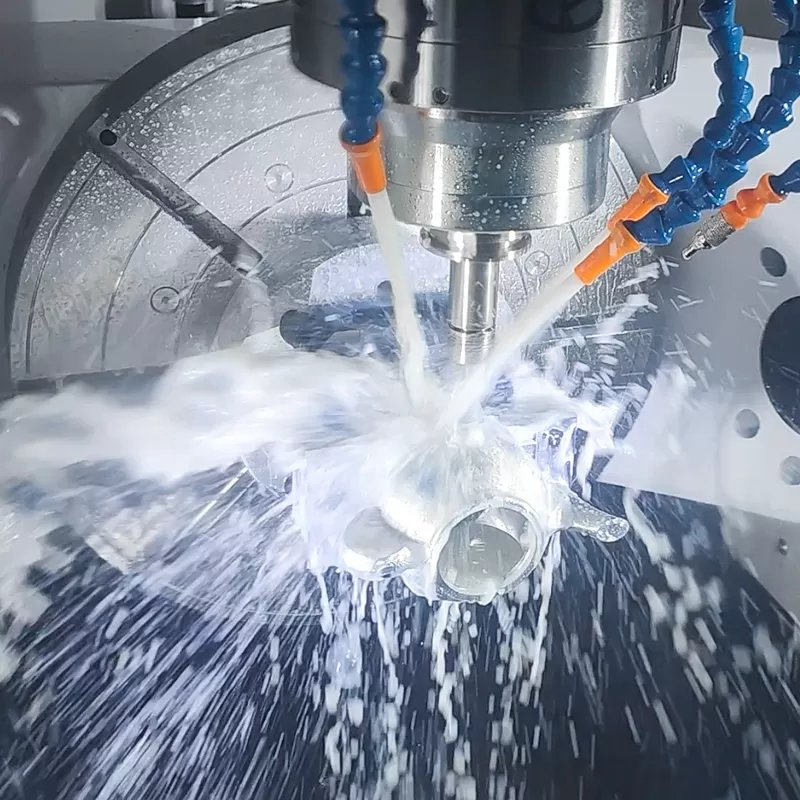

CNC machining technology provides high-precision and high-efficiency solutions for the design, manufacturing, and maintenance of aircraft and related components. The following are some important applications of CNC machining technology in the aerospace industry.

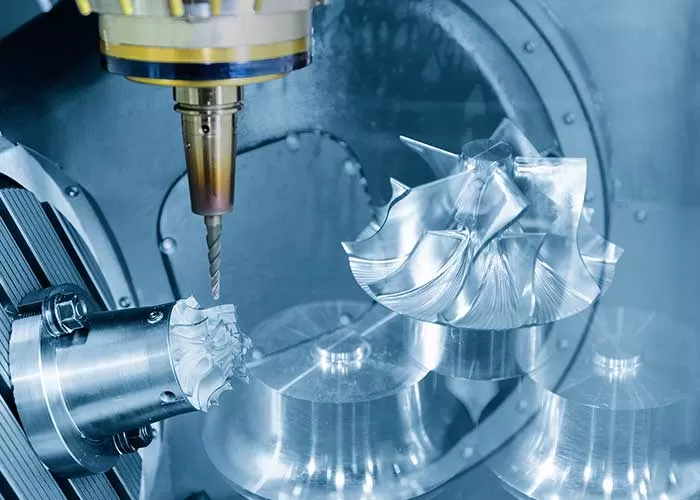

1.Manufacture of complex parts

The aerospace industry needs to manufacture a variety of complex components, such as engine components, turbine blades, turbine rotors, pneumatic parts, etc. These components require high precision, complex geometry and strict quality standards. CNC machining technology enables precise cutting, milling, drilling, etc., to produce parts that meet high standards.

2.High precision prototyping

In the aerospace industry, new aircraft designs are subject to rigorous testing and validation. CNC machining technology can be used to manufacture high-precision prototype parts for testing and evaluation. This helps the design team to better understand the feasibility of the design, optimize performance and validate the design concept of the vehicle.

3.Lightweight parts manufacturing

Lightweighting is a key trend in the aerospace industry, aiming to reduce the weight of aircraft and improve fuel efficiency. CNC machining technology allows cutting and machining with high-strength materials, resulting in lightweight, high-strength parts. This helps to reduce the overall weight of the vehicle and improve its performance and efficiency.

4.Aeroengine manufacturing

Aero-engine is the core component of aircraft, which requires high accuracy and reliability. CNC machining technology plays a key role in engine manufacturing, and can manufacture high-precision components such as blades, blade rings, and combustion chambers. This helps to improve the efficiency, thrust and life of the engine.

5.Spacecraft shell and hull manufacturing

The hull and hull of the spacecraft need to be robust and durable to withstand the challenges of the space environment. CNC machining technology can manufacture complex spacecraft shells and hull structures, ensuring their durability and safety.

6.Repair and replacement of high precision components

Parts maintenance and replacement in the aerospace industry require high precision. CNC machining technology can be used to create high-precision replacement parts to ensure that aircraft performance and safety are maintained during maintenance.

Mold manufacturing

The mold manufacturing industry relies on the high precision, flexibility, and applicability of complex design of CNC machining technology. Mold manufacturing involves the manufacturing of various complex parts and tools, and CNC machining is one of the key processes that can meet these needs. The following are some main applications of CNC machining in the mold manufacturing industry:

1.Complex mold design and manufacturing

The mold manufacturing industry needs to manufacture a variety of complex molds for the production of plastic parts, metal parts and a variety of other products. These molds often have complex geometry and require high-precision machining. CNC machining enables precise cutting, milling and drilling to meet the design requirements of various molds.

2.prototyping

In the process of mold manufacturing, prototyping is an important link. CNC machining can quickly produce a prototype of the mold for designers and customers to evaluate and verify. This helps identify potential problems in advance, saving development time and costs.

3.Custom mold manufacturing

Molds usually need to be customized according to different production requirements. The ease of customization of CNC machining allows manufacturers to customize molds according to the needs of customers to produce parts that meet specific specifications and requirements.

4.High precision parts manufacturing

The mold manufacturing industry needs to manufacture a variety of high-precision parts for the assembly and operation of molds. CNC machining provides highly accurate cutting and machining capabilities, ensuring that each part of the mold meets strict dimensional requirements.

5.Fast production and delivery

CNC machining technology enables fast cutting and machining processes, thus speeding up the manufacturing cycle of the mold. This is essential to meet market demand and deliver products in a timely manner, especially in emergency production situations.

6.Manufacture of complex cooling systems

Molds need to be cooled during production processes such as injection molding to ensure the quality and production efficiency of parts. CNC machining can produce complex cooling systems to ensure the stable operation of molds and the quality of parts.

Medical device manufacturing

The medical device manufacturing industry has benefited greatly from CNC machining technology, which provides a wide range of possibilities for the design, production, and innovation of medical devices. CNC machining technology plays a crucial role in the medical field, from the production of medical equipment to customized tools used in surgical procedures. The following are the applications of this technology in various aspects of the medical device manufacturing industry:

1.High precision medical device manufacturing

Medical devices require high precision and stability to ensure their reliability in the medical process. CNC machining technology can manufacture precise medical device parts, such as surgical tools, instruments, monitoring equipment, etc. This high precision helps ensure the accuracy and effectiveness of medical devices in clinical operation.

2.Custom implants and prosthetics manufacturing

With CNC machining technology, medical device manufacturers can create customized implants, prosthetics, and external supports based on the individual needs of patients. Using a patient’s anatomical data, implants and prosthetics can be created that perfectly match the patient’s size and needs, thereby improving the patient’s quality of life.

3.Surgical planning and modeling

CNC machining technology can be used to create surgical planning models so that surgeons can better understand complex surgical procedures. By creating patient-specific anatomical models, surgeons can conduct surgical planning and simulation, predict possible challenges, and develop more effective surgical strategies.

4.Medical device prototyping

Prototyping is essential in the development phase of medical devices. CNC machining technology can produce high-quality prototypes of medical devices for testing and evaluation. This helps designers and engineers better understand the appearance, size, and function of devices, thereby optimizing designs and accelerating product development.

5.Bioprinting support

Bioprinting is a cutting-edge technology in the medical field that can be used to create tissues, organs and medical devices. CNC machining technology can be used for the manufacturing of bioprinting scaffolds, support structures and other parts, providing a stable basis for bioprinting and ensuring the stability and consistency of bioprinting products.

6.Medical equipment repair and replacement parts

The repair and maintenance of medical equipment requires high-precision parts. CNC machining technology can be used to create precise replacement parts to ensure that the performance and safety of medical devices are maintained during maintenance.

Electronics industry

The electronics industry applies CNC machining technology to drive product innovation, improve production efficiency, and meet constantly changing market demands. The following are the main aspects and applications of CNC machining in the electronics industry.

1.Product development simplification

The electronics industry faces rapidly changing market demands and therefore requires a faster and more flexible product development cycle. CNC machining technology makes the process from design to manufacturing more efficient, allowing for the rapid production of prototypes, prototypes, or small batch products to verify design concepts and functionality.

2.Custom enhancement

Consumer demand for personalized and customized products is increasing. CNC machining can customize various electronic parts and housings according to customer requirements, so as to meet the specific needs of different users, such as customized appearance, size, interface, etc.

3.The ability to make complex electronic devices

Electronic devices are becoming smaller and more complex, requiring high-precision machining. CNC machining provides highly accurate cutting, engraving, and drilling capabilities to create electronic parts in tiny sizes, from chip radiators to connectors and sockets.

4.Rapid market launch of innovative products

In a competitive electronics market, it is crucial to introduce new products quickly. CNC machining technology allows innovative products to be brought to market faster, as it allows prototypes and prototypes of new designs to be made quickly for testing and market validation.

5.Increased design flexibility

The design of electronic devices may constantly change due to application, function or user needs. CNC machining technology can flexibly adapt to design changes, by simply modifying the program and process flow, you can carry out the machining of new products or designs in a short time.

Raw material machining

CNC machining, an advanced CNC technology that not only provides highly precise machining capabilities, but also has flexibility and automation, allowing raw materials to be finely processed into various shapes and sizes to meet the needs of different industrial fields. The following are some main applications of CNC machining technology in industrial raw material machining .

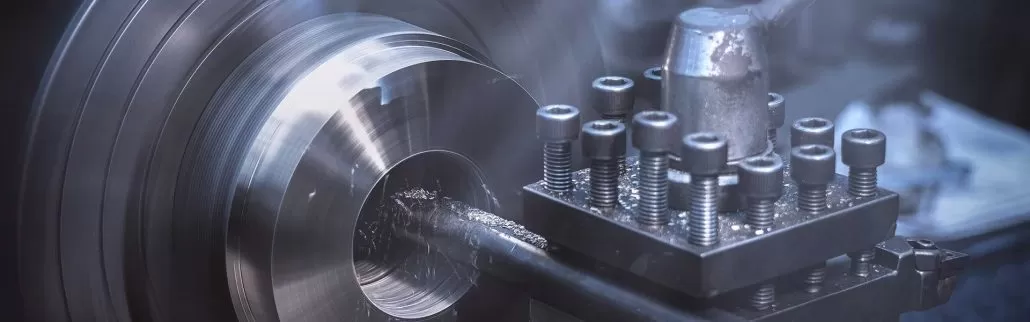

1.Metal machining

CNC machining technology is widely used in the field of metal machining , including aluminum, steel, copper, stainless steel and other metal materials. From machining parts to manufacturing complex metal structures, CNC machines enable high-precision cutting, drilling, milling and turning operations. This is widely used in aerospace, automobile manufacturing, energy industry and other industries.

2.Plastic machining

CNC machining technology is also applicable to plastic materials and can produce a variety of plastic parts and products. From plastic casings to custom plastic parts, CNC machining provides high precision plastic cutting and machining capabilities. This plays an important role in consumer goods manufacturing, electronics industry, medical device manufacturing and other fields.

3.Wood machining

Wood machining is a key part of areas such as furniture manufacturing, construction and decoration. CNC machining technology can precisely cut, carve and punch wood to produce a variety of wooden products, including furniture, doors and Windows, engraving and more.

4.Ceramics and glass machining

CNC machining technology is also suitable for the machining of brittle materials such as ceramics and glass. This technique allows fine cutting, engraving and polishing of these materials to produce complex patterns and designs for use in art, decorations and industrial applications.

5.Synthetic material machining

Synthetic materials such as carbon fiber composites are widely used in aerospace, sports equipment and automotive manufacturing. CNC machining technology allows directional cutting and drilling on these composites to meet the manufacturing needs of complex structures.

6.Hard material machining

Some industries need to process hard materials, such as ceramics, stone and cemented carbide. CNC machining technology enables high-precision cutting and engraving of these materials for the manufacture of ornaments, tools and industrial parts.

Future applications and trends of CNC machining

CNC machining technology has an expected wide application and development trend in the future of manufacturing. With the continuous progress and innovation of technology, CNC machining will continue to achieve improvements in the field of design and manufacturing, and the following are the future applications and trends of CNC machining in the manufacturing industry:

1.Further improvement of materials and capabilities

In the future, materials science and engineering technologies will continue to evolve to provide a greater variety of available materials for CNC machining. This will make it possible to manufacture parts with more characteristics, higher performance and more uses, thus expanding the range of applications for CNC machining.

2.Large-scale 3D printing and manufacturing

Combined with 3D printing technology, CNC machining will enable the manufacture of parts and components on a larger scale. Large CNC machining machines will be able to print larger and more complex objects, such as aircraft parts, building components, etc.

3.Multi-axis and multi-station machining

With the development of multi-axis and multi-station CNC machining technology, the machining efficiency and accuracy of parts will be further improved. This will allow more complex and finer parts to be manufactured efficiently for applications in automotive, aerospace and more.

4.Intelligent manufacturing and automation

The manufacturing industry will move towards intelligent manufacturing and automated production. CNC machining will be combined with robotics, artificial intelligence, etc., to achieve a higher degree of automation and intelligent machining , thereby improving production efficiency and quality.

5.Precision and micro and nano machining

With the development of micro and nano technology, CNC machining will be more and more able to achieve micro-size, high-precision machining needs, such as microelectronics, optical components and so on.

6.Digital manufacturing and virtual reality

CNC machining will be more integrated with digital manufacturing and virtual reality technology, enabling more accurate design, simulation and prediction, thereby reducing errors, saving time and costs.

7.Sustainable manufacturing and green machining

Environmental protection and sustainability are becoming increasingly important in manufacturing. CNC machining technology will tend to use more environmentally friendly materials, processes and energy sources to reduce the impact on the environment.

8.Supply chain changes

Advances in CNC machining technology will change the supply chain structure of the manufacturing industry. Due to on-site on-demand machining , inventory will be reduced, transportation costs will be saved, and production flexibility will be increased.

conclusion

CNC machining technology plays a crucial role in today’s manufacturing industry, widely used in prototype design and part manufacturing processes in various industries. From automotive manufacturing to aerospace, from medical devices to electronic products, CNC machining technology provides comprehensive solutions for different industries through its high-precision, high-efficiency, and diversified machining capabilities.

However, outsourcing to appropriate service providers is crucial to ensure high-quality CNC machining parts are obtained. In this regard, as a professional CNC machining service provider, Longsheng has rich experience and capabilities in prototype manufacturing, customized parts, and mass production, which can meet your diverse needs.

By collaborating with Longsheng, you will receive highly specialized CNC machining services, bringing excellent value and competitiveness to your projects and products.

Mobile:+86 18566759667(Gloria Wu)

E-Mail:gloria.wu@longshengmfg.com