In CNC machining , the prices of different processing projects vary. The price of a CNC machining project is determined by many factors. In most project plans, price is an important factor to consider, so we recommend that you understand the various factors of CNC machining and their impact on CNC machining pricing.

This article will help you understand the main factors that affect CNC machining pricing so that your project can reduce costs as much as possible.

What Are the Key Factors That Affect CNC Machining Pricing?

CNC machining pricing involves many aspects of thinking and is restricted by many factors. Understanding these key factors will help you gain a deeper understanding of the quote structure and make a more informed choice. Among the key factors affecting CNC machining pricing, there are a series of crucial ones:

- Machine type: CNC machine tools of different types, accuracy and performance have different costs and maintenance fees, which affect processing pricing.

- Processing efficiency: High-performance machine tools process quickly and reduce unit time costs.

- Machining accuracy: High-precision machine tools can meet higher quality requirements, which may bring additional costs.

- Processing scope: The processing of complex parts usually requires higher-level machine tools and technology, affecting pricing.

- Material costs: The type and quantity of materials being processed also affects processing costs.

- Process complexity: the number and difficulty of processes involved in the processing.

- Batch size: Larger batch production may reduce unit price through economies of scale.

- Labor cost: operator’s skill level and salary cost.

- Additional services: Additional service fees such as design support, quality inspection, packaging and transportation.

How does machine type affect CNC machining pricing?

Machine type is an important factor affecting CNC machining pricing. Different types of CNC machine tools have differences in performance, accuracy, processing range, and efficiency. These differences directly lead to differences in processing costs. High-performance, high-precision machine tools are usually expensive and have high maintenance costs, so their processing costs are relatively high. Although ordinary machine tools may have slightly lower processing accuracy and efficiency, their purchase and maintenance costs are lower, so the processing costs are also more affordable. Therefore, choosing the type of machine that suits your processing needs is crucial to controlling CNC machining costs.

Case:

Assume that an aluminum alloy part needs to be processed, the material cost is 80 yuan, and the processing time is 1 hour.

Using an ordinary three-axis CNC machine tool:

The machine tool operating cost is 90 yuan per hour, the tool loss cost is 20 yuan, and the labor cost is 60 yuan. The processing cost is: 80 yuan (material) + 90 yuan (machine tool) + 20 yuan (tool) + 60 yuan (labor) = 250 yuan.

Using a high-speed five-axis CNC machine tool:

The operating cost of the machine tool is 160 yuan per hour, but due to the improvement of machining efficiency, the processing time is shortened to 0.5 hours, the tool loss cost is 30 yuan, and the labor cost is 50 yuan. Then the processing cost is: 100 yuan (material) + 80 yuan (machine tool) + 30 yuan (tool) + 50 yuan (labor) = 260 yuan.

High-speed five-axis CNC machine tools have high operating costs, but they have high machining efficiency and shorten cycle times. The overall cost is similar to three-axis machine tools. It has advantages in machining complex parts, with high precision and high added value.

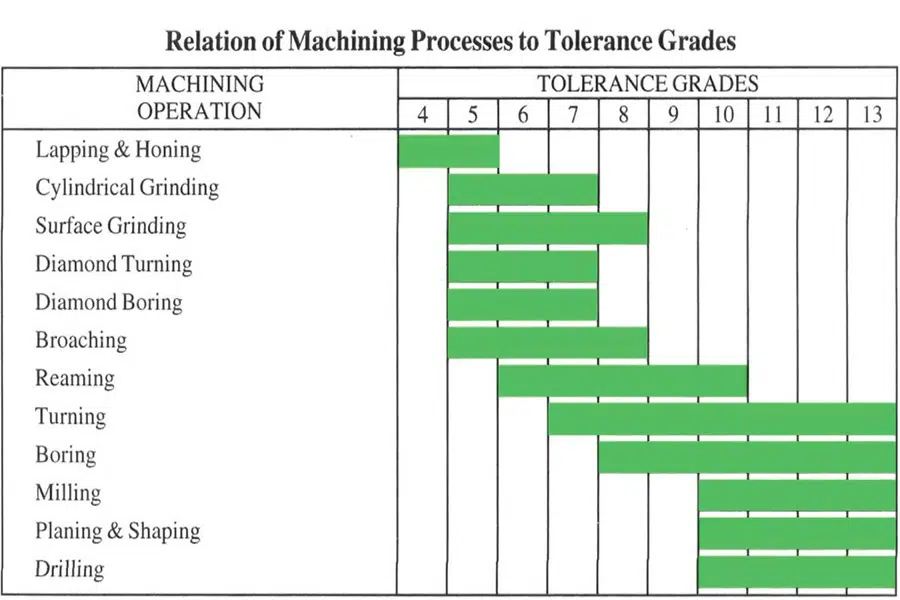

How Do Tolerances and Precision Affect CNC Machining Pricing?

The impact of tolerance and accuracy on CNC machining pricing is mainly reflected in machining difficulty, time cost and material loss. The smaller the tolerance and the higher the precision requirements, the more difficult the machining and the longer it takes. Equipment loss and material waste may also increase, leading to higher prices.

Case:

Assuming that a shaft with a diameter of 50mm is processed, the cost difference under different tolerance requirements:

| Tolerance requirements (mm) | Processing time (hours) | Cost (yuan) |

|---|---|---|

| ±0.1 | 1 | 100 |

| ±0.01 | 2 | 200 |

| ±0.001 | 4 | 400 |

Conclusion: The higher the tolerance and accuracy requirements, the higher the machining cost.

How Does CNC Machining Volume Influence Pricing?

CNC machining volume, that is, the number of products or batch size that needs to be processed, directly affects machining pricing. High-volume machining can usually spread fixed costs (such as equipment depreciation, programming fees, etc.), thereby reducing the processing cost per unit product. Conversely, low-volume or custom machining may require a higher unit price because the fixed costs cannot be spread over a large number of products and may require more setup and adjustment time.

Case:

Assume that the basic cost of machining a part is 50 yuan (including setup time and materials), and for each additional part, the additional cost is 10 yuan.

| Machining volume (pieces) | Total cost (yuan) | Unit cost (yuan) |

|---|---|---|

| 1 | 60 | 60 |

| 10 | 150 | 15 |

| 100 | 1050 | 10.5 |

Conclusion: The greater the processing volume, the lower the unit cost, which reflects the economies of scale effect.

How Does Setup Time Affect CNC Machining Costs?

Setup time is the time required for equipment debugging, fixture installation, tool replacement and other preparations before CNC machining. Longer setup time increases machining costs because it does not directly generate product value but is an integral part of the machining process. Optimizing setup time, such as through standardized operating procedures and the use of quick tool change systems, can effectively reduce processing costs.

Case:

Assume that the setup time is 2 hours, the hourly cost is 100 yuan, and it takes 0.5 hours to process a part, and the hourly cost is 50 yuan.

| Machining volume (pieces) | Setup cost (yuan) | Processing cost (yuan) | Total cost (yuan) | Unit cost (yuan) |

| 1 | 200 | 25 | 225 | 225 |

| 10 | 200 | 250 | 450 | 45 |

| 100 | 200 | 2500 | 2700 | 27 |

Conclusion: Setup time is a fixed cost. The greater the processing volume, the lower the allocation of setup costs in the unit cost.

How Do Post-Processing Steps Affect CNC Machining Pricing?

Post-processing steps, such as deburring, cleaning, heat treatment, surface treatment, etc., are further machining of the product after CNC machining is completed. These steps increase machining time and material costs, thereby affecting machining pricing. Different post-processing requirements correspond to different costs, so customers should clarify their post-processing requirements when customizing machining services so that the machining factory can provide accurate quotations.

Case:

Assuming that the machining cost of a part is 100 yuan, the additional costs of different post-processing steps are as follows:

| Post-processing steps | Additional cost (yuan) | Total cost (yuan) |

| No post-processing | 0 | 100 |

| Polishing | 10 | 110 |

| Plating | 40 | 140 |

| Heat treatment + polishing | 80 | 180 |

Conclusion: The more and more complex the post-processing steps, the higher the machining costs and the pricing will increase accordingly.

How Does Lead Time Affect CNC Machining Pricing?

The impact of delivery time on CNC machining pricing is mainly reflected in two aspects: first, urgent orders may require overtime or the deployment of additional resources to meet delivery requirements, thereby increasing costs; second, long-term orders may cause cost changes due to factors such as raw material price fluctuations and equipment wear and tear. Therefore, reasonable delivery time planning helps control machining costs while ensuring product quality and delivery time.

Case:

Assume that the normal delivery time is 5 days and the cost is 100 yuan; the expedited delivery time is 2 days and the cost increases by 50%.

| Delivery time (days) | Cost (yuan) |

|---|---|

| 5 | 100 |

| 2 | 150 |

| 1 | 200 |

Conclusion: The shorter the delivery time, the higher the processing cost and the pricing will increase accordingly.

How Does CNC Machining Tool Wear and Maintenance Impact Pricing?

Machine tool wear and maintenance costs will be allocated to the processing cost of a single piece. The greater the processing volume, the lower the cost allocated to a single piece.

Case:

Assume that the annual maintenance cost of a CNC machine tool is 10,000 yuan, the annual processing volume is 1,000 pieces, and the maintenance cost is allocated 10 yuan per piece. If the processing volume increases to 2,000 pieces, 5 yuan will be allocated to each piece.

| Annual processing volume (pieces) | Annual maintenance cost (yuan) | Maintenance cost per piece (yuan) |

|---|---|---|

| 1,000 | 10,000 | 10 |

| 2,000 | 10,000 | 5 |

| 5,000 | 10,000 | 2 |

Why Choose Longsheng’s Custom CNC Machining Services

Choose our precision CNC machining manufacturers and you’ll receive high quality, custom parts, fast delivery and competitive pricing. We’ll work with you to provide an outstanding CNC machining solution for your project.

- Multi-material machining:We have the ability to handle a variety of materials, no matter what material you need to process CNC parts, we can provide professional solutions.

- Competitive price:We provide competitive prices and cost-effective solutions to ensure that customers gain the greatest advantage in cost control.

- Customized services:Customized solutions are provided based on customers’ design requirements and specifications to ensure CNC parts meet their unique needs.

- Fast delivery:We have efficient production processes and flexible production plans, allowing us to deliver customer orders in a timely manner and meet urgent project needs.

How to get a reasonable CNC machining quote?

Now that you understand the advantages of Longsheng, we invite you to contact us and start working with us.

- Request a Quote: Get a customized online quote based on your specific needs.

- Schedule a consultation: Schedule a free consultation with our engineers,

- Contact Us: Our team is ready to assist you with all your needs.

Conclusion

CNC machining pricing is influenced by a variety of factors, such as material selection, machine complexity, part design, tolerances, and post-processing requirements. Understanding these factors can help you make a more informed decision when choosing CNC machining services. When choosing a processing plant and pricing method, it is recommended that customers fully communicate with the machining plant and clarify various costs to ensure smooth cooperation between the two parties.

Contact us now to get exclusive customized CNC machining solutions!

📞 Phone: +86 185 6675 9667

📧 Email: info@longshengmfg.com

🌐 Website: https://www.longshengmfg.com/

Disclaimer

The content appearing on this webpage is for informational purposes only. LongSheng makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LongSheng’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LongSheng

This article was written by various LongSheng contributors. LongSheng is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

FAQs

How do you calculate processing costs?

When we calculate processing costs, we usually consider the following main factors: material costs (including the purchase and processing costs of raw materials), labor costs (including labor costs for programmers, manufacturing engineers and operators), equipment costs (including depreciation, maintenance and energy consumption costs of machine tools), tool and consumable costs (such as coolant, fixtures, etc.), processing time costs (calculated based on the hourly rate of machine tools) and possible additional service costs (such as design support, quality inspection and packaging and transportation, etc.). Taking these factors into consideration, we arrive at a relatively accurate estimate of processing costs.

How much do I charge for CNC work?

How much you charge for CNC work depends on a number of factors, including but not limited to part complexity, material type, machining accuracy requirements, production batch size, and labor costs and market conditions in your area. Usually, we will determine the final charge based on the processing cost plus a certain profit. In order to obtain a more accurate quotation, it is recommended that you provide detailed part drawings and processing requirements so that we can make an accurate cost estimate and quotation.

How to estimate CNC machining time?

Estimating CNC machining time often requires consideration of factors such as part geometry, material type, tool selection, and cutting parameters. We can use CAM software to simulate processing and estimate processing time based on the simulation results. In addition, the machine tool tool change time, workpiece clamping time and possible program adjustment time also need to be considered. In order to obtain a more accurate processing time estimate, it is recommended to conduct sufficient process planning and preparation before processing.

Why is CNC machining expensive?

The high cost of CNC processing is mainly caused by the following factors: first, the purchase and maintenance cost of high-performance CNC machine tools is high; second, the processing of high-precision and complex parts requires more sophisticated tool and process control, which increases the difficulty and cost of processing; in addition, labor cost is also a part that cannot be ignored, especially when highly specialized technical personnel are required; finally, material costs may also have a significant impact on the total processing cost, especially when expensive or special materials are used. Therefore, the high cost of CNC machining is the result of a combination of factors.

Pingback: What Are the Hidden Costs in CNC Machining?

Pingback: How to Compare CNC Machining Prices?

Pingback: How to Request an Accurate CNC Machining Quote?