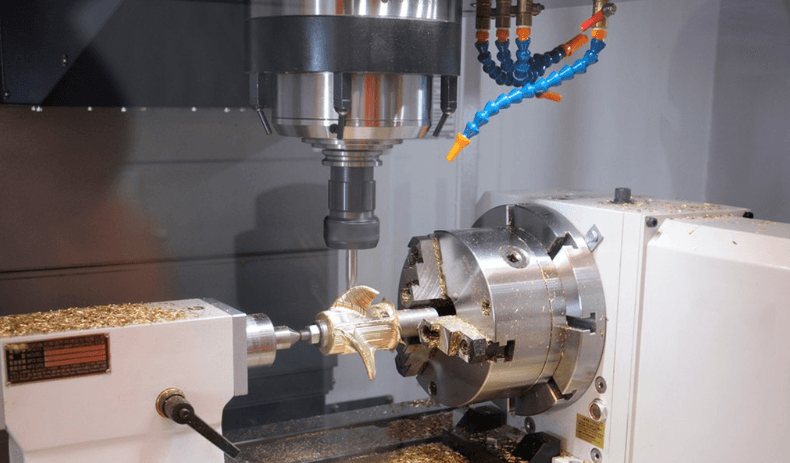

CNC machining service is a manufacturing process that involves the use of computer numerical control (CNC) machines to produce precision parts and components. These machines are programmed using computer-aided design (CAD) software and can produce parts with high accuracy and consistency.

CNC machining service is used in a wide range of industries, including aerospace, automotive, medical, and electronics. It can be used to produce parts made from various materials, including metals, plastics, and composites.

How does CNC machining service work?

CNC machining service works by using a computer-controlled machine to remove material from a workpiece to create a desired shape or design. The machine is programmed using CAD software, which generates a set of instructions that the machine follows to produce the part.

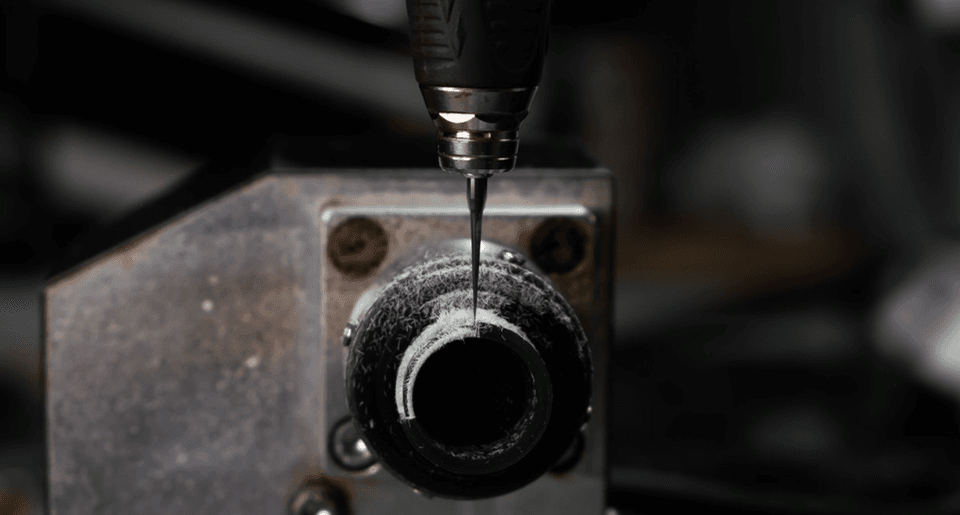

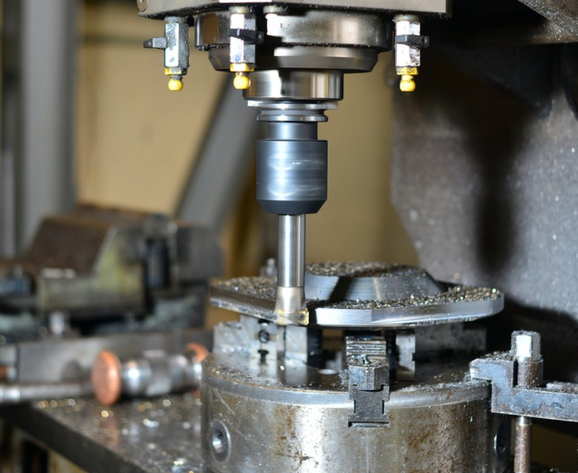

The workpiece is secured in place on a fixture or a machine table, and the cutting tool is mounted on a spindle that moves along multiple axes. The cutting tool removes material from the workpiece, creating the desired shape or design.

CNC machining service can produce complex parts with high accuracy and precision. It can also produce parts with a high degree of consistency, which is important in many industries where parts must meet strict quality standards.

Benefits of CNC machining service

CNC machining service offers several benefits over traditional manufacturing methods, including:

- High accuracy and precision: CNC machining service can produce parts with a high degree of accuracy and precision, which is important in many industries where parts must fit together perfectly.

- Consistency: CNC machining service can produce parts with a high degree of consistency, which is important in industries where parts must meet strict quality standards.

- Flexibility: CNC machining service can be used to produce parts made from a wide range of materials, including metals, plastics, and composites.

- Cost-effective: CNC machining service can be cost-effective, especially for producing small to medium-sized batches of parts.

- Customization: CNC machining service can be used to produce custom parts that are tailored to a specific application or design.

Conclusion

CNC machining service is a powerful manufacturing process that offers many benefits over traditional manufacturing methods. It can produce precision parts with a high degree of accuracy and consistency, and can be used to produce parts made from a wide range of materials. If you need precision parts for your project or application, CNC machining service may be the solution you are looking for.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC machining parts service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items