CNC (Laptop Numerical Management) machining is a vital manufacturing process within the aerospace business because of its means to supply high-quality parts with tight tolerances, excessive precision, and velocity. It is extensively used throughout all sectors inside the business, together with the manufacturing of plane engines, touchdown gears, structural frames, management methods, and even intricate elements inside the cockpit and engine.

Introduction to CNC Machining

Definition of CNC Machining

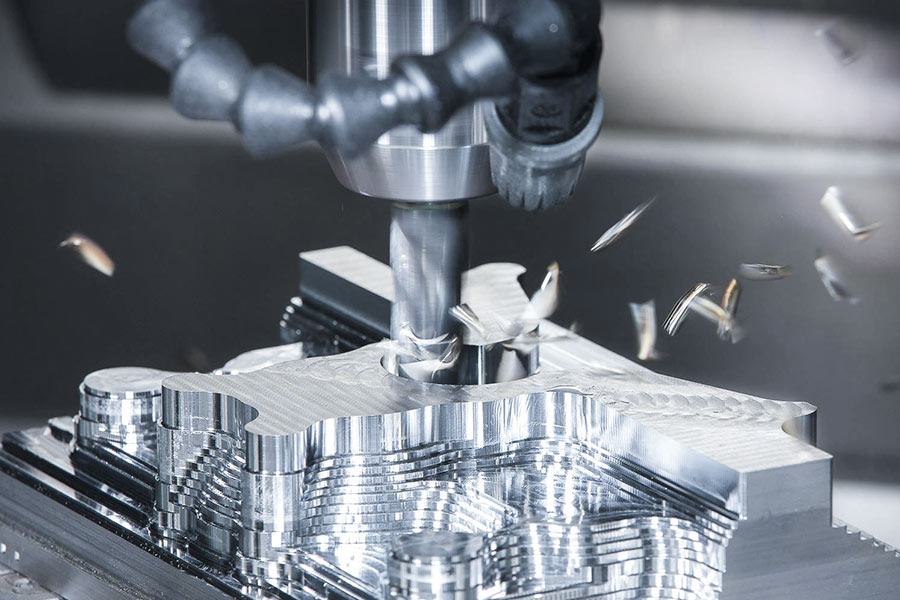

CNC (Laptop Numerical Management) machining is a producing process the place pre-programmed pc software program dictates the motion of manufacturing unit instruments and equipment. This management system is able to managing advanced collection of operations, usually carried out in three-dimensional house.

Working Precept of CNC Machining

The working precept of CNC machining entails utilizing a pc program to regulate the movement of mechanical tools. These tools embody milling machines, lathes, and cutters. First, an engineer or machinist designs a component in Laptop-Aided Design (CAD) software program. Then, this design is transformed into a pc program, which guides the CNC machine on learn how to manufacture this half. The CNC machine strikes the instrument precisely in response to this program to chop and form the uncooked materials, thereby manufacturing the exact half.

Advantages of CNC Machining

The benefits of CNC machining embody excessive precision, excessive repeatability, flexibility, and automation. On account of its accuracy and repeatability, CNC machining can produce advanced parts, which is unachievable in handbook or conventional mechanical processing. Moreover, as soon as programmed, CNC machines can function constantly with minimal supervision. This makes CNC machining very appropriate for large-scale manufacturing.

Application of CNC Machining in Aerospace Trade

Typical Elements of CNC Machining

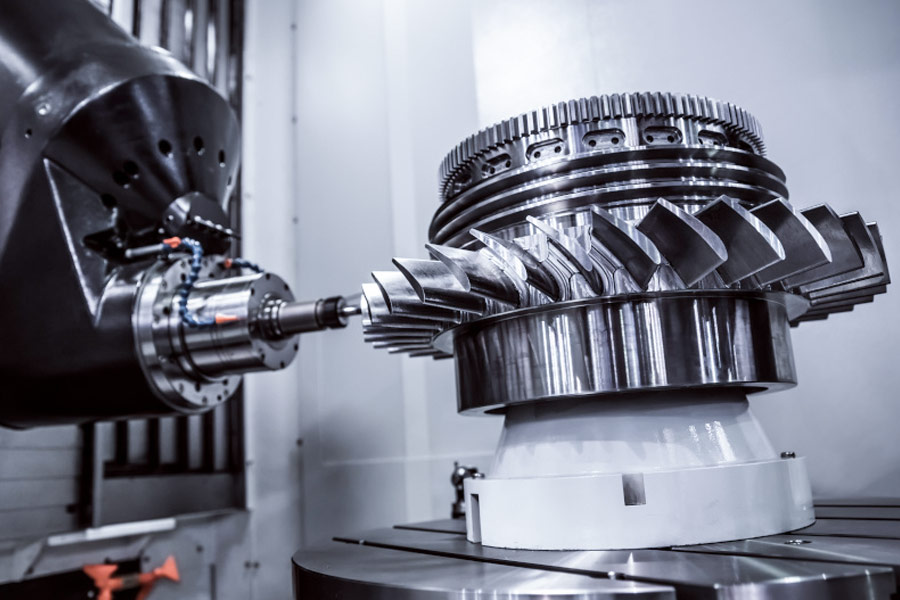

Within the aerospace business, CNC machining is used to supply a wide range of advanced and exact parts, together with varied parts of plane engines, wings and fuselage of plane, structural elements of satellites, and steerage methods of missiles. CNC machining can be used to fabricate the inner elements of plane, resembling seats, dashboards, and air-con methods.

Advantages of CNC Machining in Aerospace Manufacturing

The benefits of CNC machining in aerospace manufacturing lie in its means to supply high-precision, high-quality parts, and meet the strict calls for of the aerospace business for half precision and high quality. As well as, the automation and effectivity of CNC machining make it able to quickly producing a lot of parts, which is essential for the large-scale manufacturing of the aerospace business.

Utility of CNC Machining in Aerospace Design

In aerospace design, the appliance of CNC machining permits designers to design extra advanced and exact parts. These parts could be manufactured precisely by means of CNC machining, thereby selling the event of aerospace know-how. Moreover, CNC machining permits designers to hold out fast prototyping and testing through the design process, thereby bettering the effectivity and high quality of design.

Most Generally Used CNC Machining Gear within the Aerospace Trade

| Gear Kind | Description | Utility | Significance |

|---|---|---|---|

| CNC Lathes and Turning Machines | Machines that rotate supplies to create inside and exterior options like holes, bores, and threads. | Used for parts which are symmetrical round an axis, resembling shafts and propellers. | Important for producing axially symmetric parts. |

| CNC Milling Machines | Identified for rotating slicing instruments whereas the fabric is stationary, producing varied shapes. | Manufacturing of plane elements resembling fuselage, wings, engine parts, and cockpit elements. | Key tools for advanced 3D parts, particularly 5-axis milling machines for advanced elements. |

| CNC Laser Machines | Make the most of a targeted laser beam for slicing, slicing, or engraving supplies. | Half marking and ornament of machined elements. | Not as widespread as milling machines and lathes however necessary for particular functions. |

| CNC Electrical Discharge Machines (EDM) | Use managed electrical sparks to form supplies, creating micro holes, slots, and angled options. | Creating exact and complicated elements that require micro options. | Specialised functions inside aerospace manufacturing. |

| CNC Plasma Cutting Machines | Make use of a computer-controlled plasma torch to chop conductive supplies. | Cutting steel, stainless steel, and aluminum parts for aerospace constructions. | Helpful for slicing thick supplies shortly and exactly. |

Within the aerospace business, CNC machining’s versatility and precision make it a beneficial asset within the producer’s toolkit. CNC lathes and turning machines are important for producing axially symmetric parts. CNC milling machines are the important thing tools for advanced 3D parts, with 5-axis milling machines being significantly helpful for advanced plane elements. CNC laser machines, whereas not as widespread, play a task partly marking and ornament. CNC EDMs are used for creating exact micro options, and CNC plasma slicing machines are helpful for slicing conductive supplies shortly and exactly. These machines’ exact management and environment friendly manufacturing capabilities allow the aerospace business to supply high-quality parts that meet strict requirements and complicated designs.

Future Improvement Traits of CNC Machining within the Aerospace Trade

Composite Materials Processing

The aerospace business is more and more turning to superior supplies and composites, resembling carbon fiber composites, titanium alloys, and different light-weight alloys, for his or her distinctive strength-to-weight ratios, corrosion resistance, and fatigue properties. The processing of those supplies presents new challenges in comparison with conventional steel machining, as composites mix completely different supplies to create distinctive properties. Structural supplies for aerospace are driving innovation in composites, including stiffness, energy, and sturdiness to airframes. The standard of holes, instrument life, and gear price are important components within the productiveness of composite machining, and steady innovation is required to fulfill the calls for of those functions.

Additive Manufacturing

Additive manufacturing, or 3D printing, is revolutionizing aerospace manufacturing by enabling the layer-by-layer deposition of supplies to create intricate and complicated elements with precision. This know-how permits for the consolidation of a number of parts right into a single part, lowering meeting complexity, weight, and potential factors of failure. It additionally offers unprecedented design freedom, enabling engineers to discover modern shapes and configurations that had been beforehand unfeasible with conventional manufacturing strategies. Whereas providing effectivity positive aspects and important price financial savings, the widespread adoption of additive manufacturing faces challenges. However, it represents a transformative shift within the aerospace business, promising to redefine aerospace design and manufacturing because the know-how evolves.

Clever Manufacturing

Automation and clever manufacturing have gotten more and more necessary within the aerospace sector. Using robotics, AI, and ML algorithms is important for enhancing the capabilities of CNC machining. The mixing of CNC machining with linked manufacturing ecosystems permits for seamless digital communication between machines, manufacturing planning methods, provide chains, and high quality management. Developments in multi-axis machining, simultaneous milling, and adaptive machining strategies are enabling the manufacturing of extra advanced elements with tight tolerances and superior floor finishes. The mixing of CNC machining with additive manufacturing processes unlocks new potentialities, resembling post-processing and including closing particulars to 3D-printed parts.

Working within the aerospace sector requires precision, as there isn’t any margin for error. Parts should meet stringent business requirements to stop catastrophic failure. Steady enchancment is a mainstay, incorporating a tradition of ongoing analysis and refinement, in search of operator suggestions, and investing in worker coaching. Streamlining CNC machining processes by means of process optimization and implementing lean manufacturing ideas are essential for enhancing effectivity. Embracing rising applied sciences and nurturing extremely expert groups are important for sustaining a aggressive benefit within the aerospace CNC manufacturing panorama.

The way forward for CNC machine instruments within the aerospace business can be characterised by the necessity for high-speed processing, significantly for brand new supplies like aluminum alloy. Bettering management accuracy, error compensation know-how, and movement trajectory accuracy is essential for guaranteeing excessive precision within the machining process. The idea of composite machine instruments, which permits for the processing of a number of components from the clean to the completed product on a single machine instrument, is resulting in improved manufacturing effectivity and market response functionality.

Why select LongSheng CNC machining utilized in aerospace business?

The aerospace business has extraordinarily excessive necessities for the precision and high quality of parts, so when selecting CNC machining tools, the precision, stability, and reliability of the tools have to be thought of. Longsheng, as a widely known CNC machine instrument producer, performs properly in these features.

Firstly, Longsheng’s CNC machine instruments have excessive precision, which might meet the strict necessities of the aerospace business for half accuracy. Secondly, Longsheng’s CNC machine instruments have good stability, which might guarantee steady work for a very long time with out being affected by machine failures, thus affecting the manufacturing schedule. Lastly, Longsheng’s CNC machine instruments have robust reliability and lengthy service life, which might cut back the upkeep price and substitute frequency of the tools.

As well as, Longsheng additionally offers complete after-sales companies, together with tools set up, debugging, and upkeep, which is a crucial cause why the aerospace business chooses Longsheng.

Conclusion

CNC machining is extensively used within the aerospace business for producing and sustaining plane and house parts. It’s a computerized manufacturing methodology that strikes slicing instruments utilizing pre-programmed code and software program, permitting for the creation of high-performance parts with rugged energy, superior precision, and tight tolerances. Aerospace CNC machining is essential for attaining extraordinarily tight tolerances for each plastic and steel parts, and it’s employed in varied functions resembling creating light-weight and powerful plastic parts with advanced designs, producing aerospace-grade plastics and metals, and manufacturing important CNC machined elements instruments precisely and shortly to make sure correct functioning of plane elements. The aerospace business depends on CNC machining for its means to realize precision, consistency, and effectivity, making it a great match for aerospace half manufacturing.

FAQs

What supplies are generally utilized in aerospace CNC machining?

Materials regularly utilized in aerospace CNC machining embody a wide range of metals and plastics. Particularly, titanium, aluminum, stainless steel, copper, bronze, and sure forms of plastics are widespread. The business additionally depends on superior composite supplies, resembling carbon fiber composites and titanium alloys, because of their energy, light-weight traits, and resistance to excessive situations.

What are some great benefits of CNC machining in comparison with conventional machining strategies?

CNC machining provides a number of benefits over conventional machining strategies. These embody excessive precision and strict tolerances, the power to constantly replicate parts with unimaginable precision, and the manufacturing of advanced geometries and complicated options. CNC machining can be automated, which reduces the necessity for handbook intervention and minimizes potential human errors, and it could actually work with a variety of supplies. Moreover, CNC machining processes could be optimized for velocity and effectivity, leading to sooner manufacturing cycles and decreased lead instances. In comparison with handbook machining, CNC machining usually has a decrease whole price because of components resembling decrease scrap charges and decreased labor and upkeep necessities.

How a lot does CNC machining price within the aerospace business?

The price of CNC machining within the aerospace business can range extensively based mostly on particular necessities, supplies used, and the complexity and amount of the elements being produced. Whereas particular price particulars will not be offered within the given content material, it’s famous that the preliminary funding for CNC machining could be comparatively excessive, however for bigger manufacturing portions, the unit worth might lower, lowering manufacturing prices.

What are some CNC machining corporations within the aerospace business?

Whereas particular names of CNC machining corporations within the aerospace business will not be offered within the given content material, corporations like RapidDirect are talked about as being concerned in aerospace CNC machining, offering precision CNC machining for aerospace prototypes and end-use elements. Moreover, corporations like (Jie Bai Rui Expertise Co., Ltd.) are famous for offering precision machining companies for varied industries, together with aerospace.

Rource

What is CNC machining? ─ The first lesson about CNC machining