This document provides an overview of CNC Turning – a manufacturing process that involves the use of computer-controlled machines to create precision parts and components. CNC Turning is a highly precise and efficient manufacturing method that is widely used in industries such as aerospace, automotive, and medical devices.

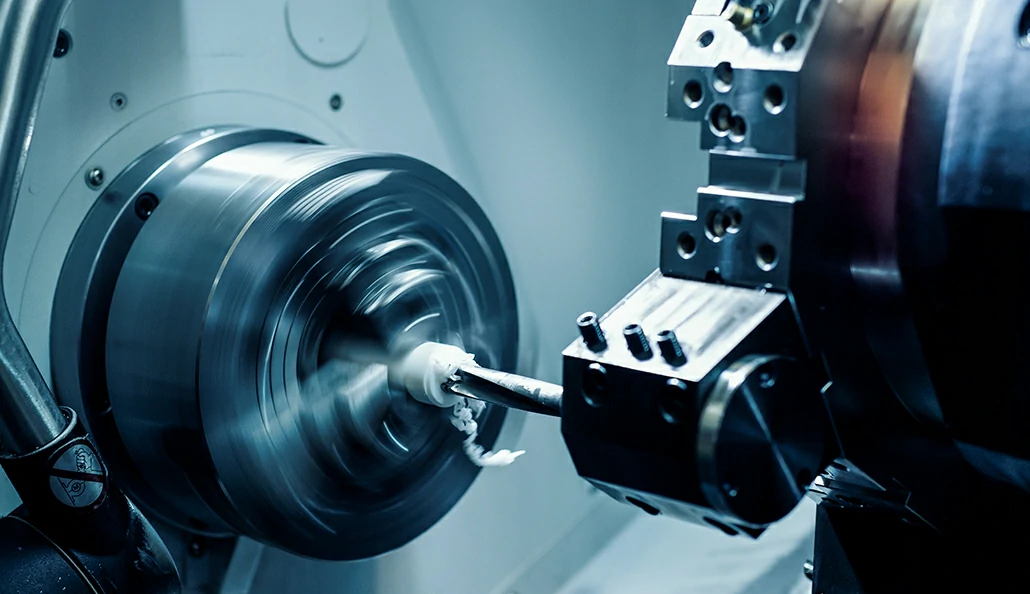

The process involves the use of a lathe machine, which rotates a workpiece while a cutting tool removes material from the surface of the workpiece to create the desired shape. The cutting tool is controlled by a computer program that specifies the exact dimensions and specifications of the part being produced.

CNC Turning is capable of producing complex geometries and tight tolerances with high accuracy and consistency. The process is highly automated and can run continuously for long periods of time with minimal human intervention.

what is cnc turning machining?

CNC Turning Machining is a manufacturing process that involves the use of computer-controlled machines to produce precision parts and components. The process involves the use of a lathe or turning machine, which rotates a workpiece while a cutting tool removes material from the surface of the workpiece to create the desired shape and size.

CNC Turning Machining offers several advantages over traditional manual turning, including increased accuracy, consistency, and speed of production. The use of computer-controlled machines also allows for more complex designs and shapes to be produced with ease.

The CNC Turning Machining process is widely used in various industries, including aerospace, automotive, medical, and electronics, to produce parts and components such as shafts, bolts, screws, and other cylindrical or round-shaped objects.

Overall, CNC Turning Machining is a highly efficient and precise manufacturing process that offers significant advantages over traditional manual turning, making it a popular choice for producing high-quality parts and components.

cnc turning machining definition

CNC Turning Machining is a manufacturing process that involves the use of computer-controlled machines to produce precision parts and components. This process is widely used in various industries, including aerospace, automotive, medical, and electronics, to produce parts and components such as shafts, bolts, screws, and other cylindrical or round-shaped objects.

The process involves the use of a lathe or turning machine, which rotates a workpiece while a cutting tool removes material from the surface of the workpiece to create the desired shape and size. It offers several advantages over traditional manual turning, including increased accuracy, consistency, and speed of production. The use of computer-controlled machines also allows for more complex designs and shapes to be produced with ease.

One of the significant benefits of CNC Turning Machining is its ability to produce high-quality parts and components with a high degree of precision and accuracy. The process is highly efficient and reduces the risk of errors caused by human intervention, leading to more consistent and reliable results.

The CNC Turning Machining process is also highly flexible and can be used for both small and large-scale production runs. The ability to produce parts and components quickly and accurately makes it an attractive option for many manufacturers looking to increase production rates and reduce costs.

Overall, CNC Turning Machining is a highly efficient and precise manufacturing process that offers significant advantages over traditional manual turning, making it a popular choice for producing high-quality parts and components.

cnc turning machining used

CNC Turning Machining is widely used in various industries, including aerospace, automotive, medical, and electronics, to produce parts and components such as shafts, bolts, screws, and other cylindrical or round-shaped objects. It offers several advantages over traditional manual turning, including increased accuracy, consistency, and speed of production. The ability to produce parts and components quickly and accurately makes it an attractive option for many manufacturers looking to increase production rates and reduce costs.

cnc turning machining process

CNC Turning Machining is a manufacturing process that involves the use of computer-controlled machines to produce precision parts and components. The process involves the use of a lathe or turning machine, which rotates a workpiece while a cutting tool removes material from the surface of the workpiece to create the desired shape and size. It offers several advantages over traditional manual turning, including increased accuracy, consistency, and speed of production. The use of computer-controlled machines also allows for more complex designs and shapes to be produced with ease.

One of the significant benefits of CNC Turning Machining is its ability to produce high-quality parts and components with a high degree of precision and accuracy. The process is highly efficient and reduces the risk of errors caused by human intervention, leading to more consistent and reliable results.

The CNC Turning Machining process is also highly flexible and can be used for both small and large-scale production runs. The ability to produce parts and components quickly and accurately makes it an attractive option for many manufacturers looking to increase production rates and reduce costs.

Overall, CNC Turning Machining is a highly efficient and precise manufacturing process that offers significant advantages over traditional manual turning, making it a popular choice for producing high-quality parts and components.

cnc turning machining services

If you are looking for CNC Turning Machining services, there are many companies that offer this type of manufacturing process. These companies specialize in the production of precision parts and components using computer-controlled machines and can provide a range of services, including prototyping, design, and production runs for both small and large-scale projects.

When selecting a CNC Turning Machining service provider, it is important to consider their experience, capabilities, and quality control processes. Look for a company that has a proven track record of producing high-quality parts and components and can offer competitive pricing and fast turnaround times.

Overall, CNC Turning Machining services are an excellent option for manufacturers looking to produce high-quality parts and components quickly and efficiently. With the use of computer-controlled machines, this manufacturing process offers increased accuracy, consistency, and speed of production, making it a popular choice across a range of industries.