What’s form milling?

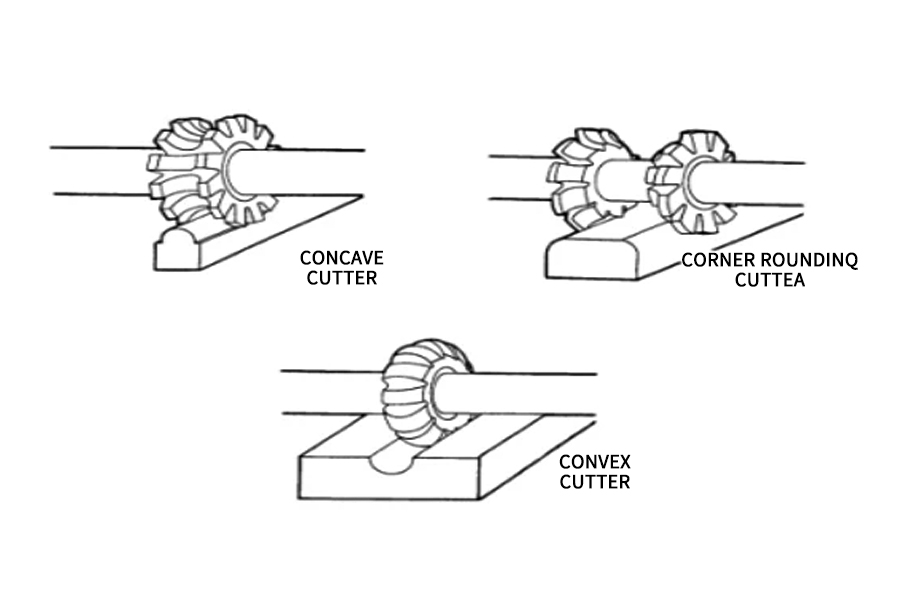

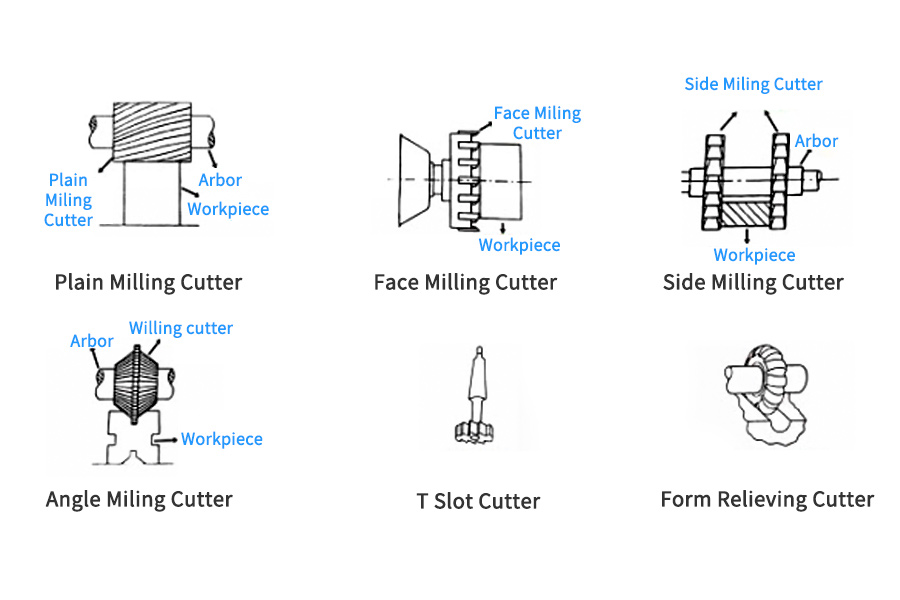

Form milling is a specialised machining process that makes use of rotating instruments to create advanced and contoured shapes on the floor of a workpiece. This know-how is especially helpful in industries corresponding to aerospace, automotive and medical, the place the necessity to produce advanced elements and molds with exact shapes is a standard demand. The process entails using {custom} formed milling instruments which can be particularly designed for the job at hand. These instruments usually have distinctive profiles that match the particular profile wants of a wide range of functions. There are additionally many forms of commonplace formed milling instruments for concave and convex curves, thread profiles, edge beads, and extra.

Form milling is extensively utilized in a wide range of industries that require advanced shapes and contours. This know-how permits producers to create custom-designed parts with excessive accuracy and repeatability. Nonetheless, when contours will be minimize with a reasonably large finish mill, form milling is probably not the best choice, as extra secure instruments can usually do the job in a single go. Nonetheless, because of its versatility and precision, form milling stays a crucial process in trendy manufacturing.

The process entails using {custom} formed milling instruments which can be particularly designed for the job at hand. These instruments usually have distinctive profiles that match the particular profile wants of a wide range of functions. There are additionally many forms of commonplace formed milling instruments for concave and convex curves, thread profiles, edge beads, and extra.

Form milling is extensively utilized in a wide range of industries that require advanced shapes and contours. This know-how permits producers to create custom-designed parts with excessive accuracy and repeatability. Nonetheless, when contours will be minimize with a reasonably large finish mill, form milling is probably not the best choice, as extra secure instruments can usually do the job in a single go. Nonetheless, because of its versatility and precision, form milling stays a crucial process in trendy manufacturing.

How does it used?

Form milling is a CNC milling operation used to provide irregular contours consisting totally of curves or curves and straight strains. On this process, formed milling instruments are used, the shapes of which correspond to the profile of the floor to be produced. This specific irregular contour will be concave, convex, or some other form. The working precept of form milling is that the milling machine can use totally different instruments to chop the fabric to realize numerous outcomes. In form milling, the form of the software precisely matches the specified profile, so advanced shapes and profiles will be machined effectively and exactly. The mechanical velocity of this operation is 20 to 30 p.c decrease than that of floor milling.

Widespread form milling operations are used to mill semi-circular grooves, beads, and quarter-circle radii. On CNC milled parts, advanced patterns or a number of advanced surfaces will be achieved by form milling. For instance, it may be used to make spiral gears.

The working precept of form milling is that the milling machine can use totally different instruments to chop the fabric to realize numerous outcomes. In form milling, the form of the software precisely matches the specified profile, so advanced shapes and profiles will be machined effectively and exactly. The mechanical velocity of this operation is 20 to 30 p.c decrease than that of floor milling.

Widespread form milling operations are used to mill semi-circular grooves, beads, and quarter-circle radii. On CNC milled parts, advanced patterns or a number of advanced surfaces will be achieved by form milling. For instance, it may be used to make spiral gears.

Advantages

Excessive precision: Forming milling can process parts with advanced shapes, and has excessive dimensional accuracy and floor end. This methodology can meet the machining necessities of high-precision parts, corresponding to parts within the aerospace and medical gadget fields. It’s because the form of the formed milling software matches the specified profile precisely, so advanced shapes and profiles will be machined effectively and exactly. Excessive effectivity: For mass-produced parts, molding milling can enhance processing effectivity and scale back manufacturing prices. This methodology can rapidly and precisely process the identical parts, which is appropriate for mass manufacturing. It’s because as soon as the proper parameters and gear path are set, the CNC milling machine can produce repeatedly with out interruption, with out frequent guide intervention. Robust applicability: molding milling can process numerous supplies of the workpiece, together with steel, non-metal, composite supplies and so forth. This methodology just isn’t restricted by supplies and may process parts of varied supplies. Form milling is able to dealing with each cemented carbide and plastics, making it very helpful in a wide range of manufacturing environments. Robust versatility: Form milling can process numerous shapes of the workpiece, together with easy shapes and sophisticated shapes. This methodology can meet the machining necessities of varied form parts. Whether or not it’s a easy airplane, or a fancy three-dimensional floor, or a part with particular geometric options, form milling will be successfully processed. Form milling has a number of different benefits. For instance, it may well present higher floor high quality as a result of the form of the software will be higher tailored to the floor of the workpiece. As well as, as a result of form milling can full a number of machining steps in a single operation, the variety of workstations will be decreased, saving house and prices. Lastly, as a result of the form milling will be managed utilizing CNC, it may be extremely automated, decreasing guide intervention and growing manufacturing effectivity.Limitations

Excessive software prices: Instruments for form milling usually should be custom-made, which signifies that their manufacturing prices are normally greater than commonplace instruments. This could improve general manufacturing prices, particularly in small batch manufacturing, the place excessive software prices can have a major influence on the whole value. Design complexity: Designing and manufacturing {custom} instruments requires a excessive stage of ability and expertise. This will likely require specialised technicians to function, growing the complexity of the manufacturing process. As well as, if the design of the part must be modified, it might be needed to revamp and manufacture the software, which is able to additional improve the fee and time. Restricted machining vary: Every {custom} software can solely work a particular form or profile. Which means the processing scope of form milling is proscribed by the software and it’s not doable to process all shapes of parts. If parts of various shapes should be machined, a number of totally different instruments could also be required, which is able to improve the fee and complexity. Gear necessities: Form milling usually requires using superior CNC milling machines, which will be pricey to buy and keep. As well as, working these units requires specialised coaching, which may improve labor prices.

Comparability between Form Milling and Airplane Milling

| Form Milling | Airplane Milling | |

|---|---|---|

| Advantages | Can process parts with advanced shapes and excessive precision | Makes use of commonplace instruments, can process parts of varied supplies, and has a large processing vary |

| Limitations | Excessive software value, advanced design, restricted processing vary, and requires using superior CNC milling machines | Might not obtain the excessive precision and sophisticated shapes of form milling |

| Utility Situations | Conditions that require processing of advanced shapes or excessive precision parts, corresponding to within the aerospace and medical gadget fields | Extra common, appropriate for parts of varied supplies and shapes, particularly when excessive precision or advanced shapes will not be required |

The selection between which milling methodology to make use of is dependent upon particular processing necessities, together with the form of the part, precision necessities, manufacturing quantity, value constraints, and different elements.

Why select LongSheng in your form milling process?

Selecting LongSheng for form milling will be helpful because of a number of causes. First, LongSheng’s experience in {custom} software design and manufacturing can guarantee high-quality, exact instruments for every particular job. This may end up in higher accuracy and repeatability within the milling process. Second, LongSheng’s superior CNC milling machines can deal with the advanced operations required in form milling, offering dependable and environment friendly manufacturing. Lastly, LongSheng’s skilled technical group can present worthwhile help within the design and manufacturing process, serving to to beat the challenges related to form milling.Conclusion

Form milling is a milling method used to create irregular, constant, and customarily advanced contours. It entails using custom-made form milling cutters, that are designed particularly for the job at hand. These cutters are sometimes manufactured with distinctive profiles that swimsuit numerous functions’ specific profile wants. Form milling is extensively utilized in numerous industries by which intricate shapes and profiles are required, corresponding to aerospace, automotive, and medical industries. This method permits producers to create custom-designed parts with excessive accuracy and repeatability.

One of many greatest benefits of form milling is its means to deal with advanced shapes and particulars. As an illustration, if a part has totally different radii, angles, or different intricate particulars, a form milling software will be designed to mill all these options without delay, growing effectivity. That is significantly helpful in conditions the place a part must be manufactured many instances over.

Nonetheless, form milling comes with its personal set of limitations. The price of the instruments will be excessive, particularly since they’re usually custom-made for every job. The design and manufacturing process for these instruments can be advanced, requiring a excessive stage of technical experience. Moreover, every software can solely process a particular form or contour, limiting the vary of parts that may be processed with a single software.

Regardless of these limitations, form milling stays a worthwhile method for producing high-precision parts with advanced shapes, significantly in industries the place such parts are required.

FAQs

What are some frequent milling strategies?

Widespread milling strategies primarily embrace airplane milling, facet milling, nook milling, gear milling, helical milling, and form milling. Every milling methodology has its particular utility eventualities and benefits. The selection of milling methodology is dependent upon the form of the part, precision necessities, manufacturing quantity, value constraints, and different elements.

What’s a form milling cutter?

A form milling cutter is a specifically designed milling cutter used to machine a particular form or profile on a workpiece. The form of the cutter enamel matches the form to be machined, permitting the form to be accomplished in a single go, enhancing machining effectivity. Form milling cutters are extensively utilized in conditions that require machining of advanced shapes or high-precision parts, corresponding to within the aerospace and medical gadget fields.

What’s forming in mechanical processing?

Forming in mechanical processing refers back to the process of machining a fabric right into a predetermined form and dimension by way of mechanical power. Forming strategies primarily embrace casting, forging, stamping, welding, warmth therapy, plastic processing, and so on. Throughout the forming process, the inner construction and properties of the fabric might change, so it’s needed to decide on the suitable forming methodology based mostly on the utilization situations and efficiency necessities of the part.