Introduction

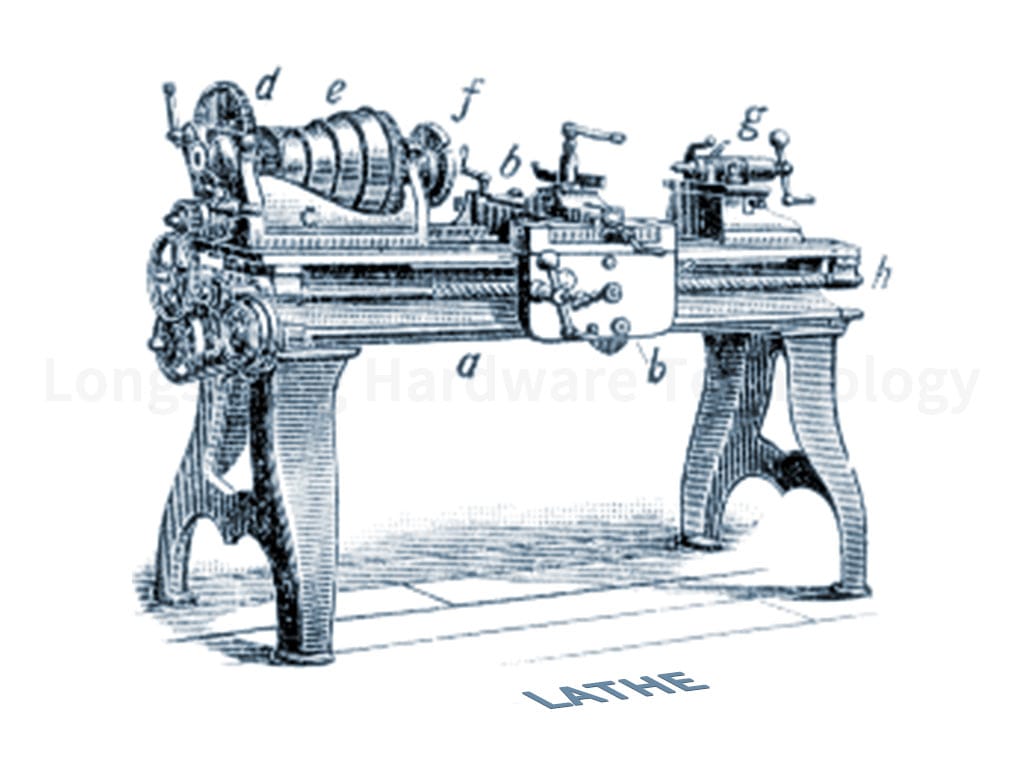

Brief history of lathe machines

Lathe machines have been a cornerstone of manufacturing and machining for centuries. The first evidence of lathe use dates back to 1300 BC in ancient Egypt. The lathe machine, often dubbed the “Mother of all machine tools,” has evolved significantly over the years, with the invention of the CNC (Computer Numerical Control) lathe marking a significant milestone in its development.

Jacques de Vaucanson invented the lathe machine around 1751. Over time, lathes advanced with the introduction of individual electric motors, which allowed for greater power and dependability. After World War II, Numerical Control Systems were developed, moving lathes away from reliance on wheels and levers for control input.

The development of various high-efficiency automatic lathes and specialized lathes accelerated rapidly after World War I due to the demands of the munitions, automobile, and other machinery industries. By the mid-1950s, program-controlled lathes with punched cards, latch plates, and dials were developed.

Introduction to CNC Lathe Machines

The use of CNC technology in lathes began in the 1960s. By the 1970s, microprocessors were directly integrated into CNC machines, further advancing the popularization and rapid development of CNC machine tools.

A CNC lathe is a computer-numeric controlled machine tool specialized in CNC turning machining, including taper turning, hard riding, spherical generation, facing, cutting off, knurling, drilling, grooving, etc. Compared to a conventional lathe, CNC lathes are operated with precise design instructions and programs to improve productivity and precision.

Modern CNC lathe machines usually have tools that can work on multiple axes, allowing more complex parts to be produced without manually switching machines or tools. Different machines can include an X and Y-axis, incorporate a second turret with other tools, or have a second spindle. This means a CNC lathe can perform additional milling, drilling, and tapping operations, resulting in a complete and even complex part manufacturing process and eliminating the need to transfer the part to another machine for a second operation. The evolution of lathe machines, particularly with the advent of CNC technology, has revolutionized the manufacturing industry. The ability to perform complex machining tasks with high precision and efficiency has made CNC lathe machines indispensable in various industries.

Understanding Lathe Cutting Tools

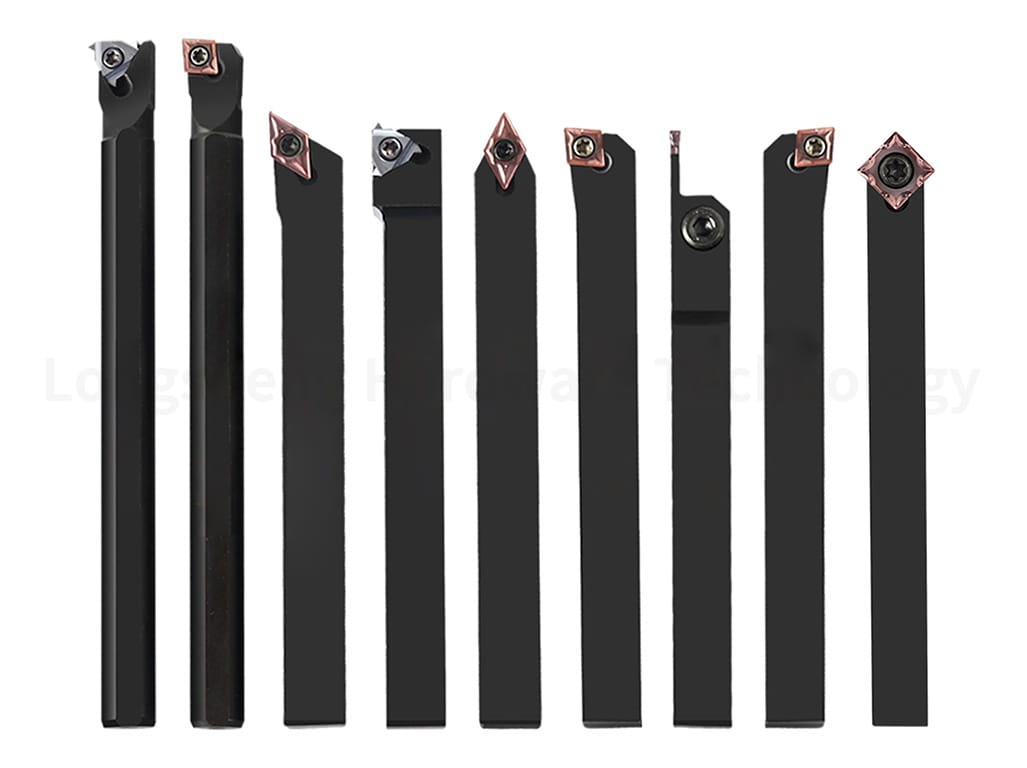

Lathe-cutting tools are essential components mounted on a lathe, whether wood, hand, or CNC lathe. They are used in producing turned parts, and their path along the lathe’s axis determines the final shape of the workpiece. These tools perform various operations such as bending, undercutting, knurling, drilling, facing, boring, and cutting. The type of tool used can vary based on the operation, with single-point cutting tools used for general-purpose work and multi-point cutting tools used for special operations.

Definition and Purpose of Lathe Cutting Tools

Lathe cutting tools are defined as tools that are applied to the workpiece to create an object with symmetry about the axis of rotation. They are used to shape wooden or metallic products by furnishing a piece while it rotates about an axis. A stationary cutting tool removes unwanted material from the workpiece to form the desired shape. These tools perform various operations such as turning, undercutting, knurling, drilling, facing, boring, and cutting, which are essential in manufacturing and machining.

The Importance of Choosing the Right Lathe Cutting Tools

Choosing suitable lathe-cutting tools is crucial for achieving the desired results in machining operations. Different operations require different types of lathe-cutting tools, and selecting the right tool requires an in-depth understanding of the tool. For instance, welding lathe-cutting tools are particularly prevalent in settings where frequent modifications are needed. In contrast, clamp lathe tools are applicable in operations where there is a constant need for replaceable tool bits used in a lathe machine.

Categories of Lathe Cutting Tools

Lathe-cutting tools can be classified into different categories based on various factors such as materials, operations, structure, and feed direction. Each category has unique features and designs that define the cutting operations and field applications supported by the lathe.

Classification Based on Materials

Lathe cutting tools can be made from various materials, each with unique properties and applications. High-speed steel is commonly used for lathe cutting tools, especially for rough and semi-finish machining. It can be continuously polished, making it a general tool for various operations. Cemented carbide blades are suitable for cutting different materials, including cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone, and ordinary steel.

Classification Based on Operations

Lathe-cutting tools are also classified based on their operations. For instance, some tools are designed for specific operations like drilling, milling, or turning. Contour turning tools, for example, follow a contoured path rather than a straight one, creating a contoured form in the curved part. Rough turning tools, on the other hand, are used to remove material from the workpiece in minimum time by applying a high rate of feed and heavy deposition of the cut.

Classification Based on Structure

The structure of lathe-cutting tools also varies. Some tools, like clamp lathe cutting tools, are formed by placing the insert (i.e., the cutting tool) on a handlebar. These tools are dexterous and replaceable, with their properties, such as strength and durability, depending on the type of inserts. Other tools, like compound or damping cutters, have unique structures designed for specific applications.

Classification Based on Feed Direction

Lathe-cutting tools can also be classified based on the direction of the feed. Right-hand lathe cutting tools, for example, remove materials when transporting them from right to left. They have a design similar to the human hand, with the right thumb indicating the direction of the feed, and the leading cutting edge is on the left side of the tool. Conversely, left-hand lathe-cutting tools operate in the opposite direction.

Different Types of Lathe Cutting Tools for CNC Lathe Machines

Lathe-cutting tools are instrumental in producing turned parts with a lathe machine and shaping materials to the desired form. They are a crucial aspect of CNC machining. To maximize the advantages of these tools, it is essential to understand the various types of lathe tools needed to perform different operations.

Detailed Description of Each Type of Lathe Cutting Tool

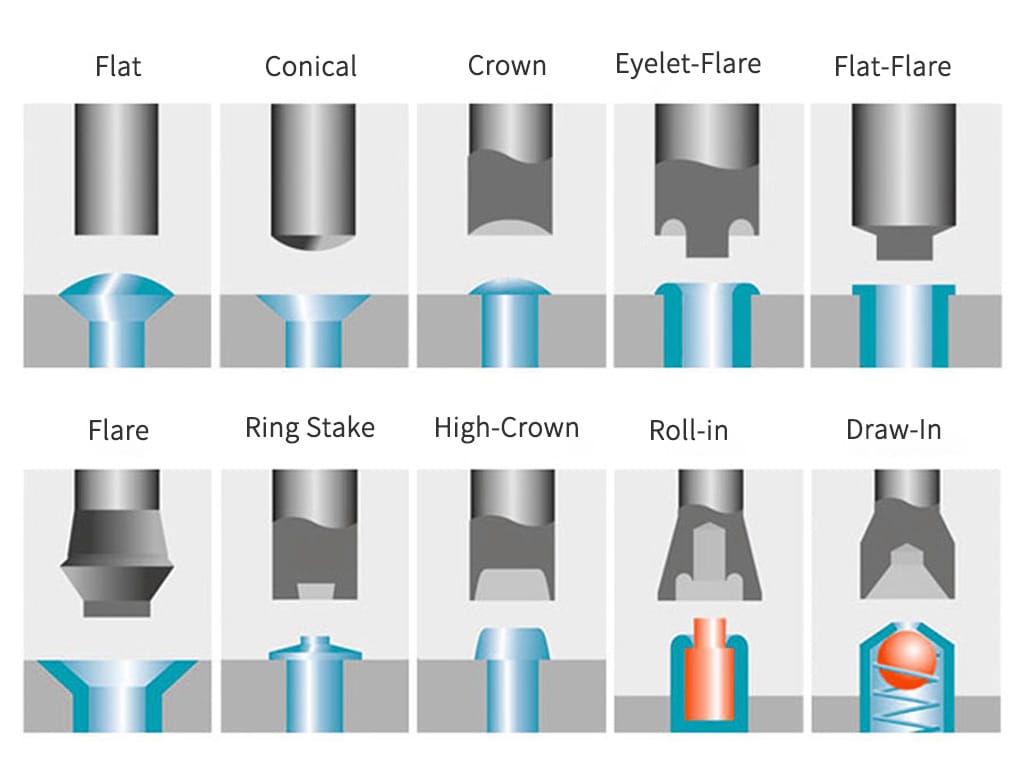

- Turning Tool: This is the most common type of lathe-cutting tool. It removes material from the workpiece to create cylindrical shapes. It can be utilized for straight turning, taper turning, and profiling.

- Chamfering Tool: This tool makes a bevel or furrow on the corner of a workpiece. It’s often used to prepare the ends of rods or bolts for threading.

- Thread Cutting Tool: This tool cuts threads on the workpiece. It can be utilized for both internal and external thread cutting.

- Facing Tool: This tool cuts the end surface of a workpiece, making it flat. It’s often employed at the beginning or end of a turning operation.

- Grooving Tool: This tool makes grooves or recesses on the surface of a workpiece. It’s often used with other tools to create specific features on a part.

- Forming Tool: This tool creates complex shapes on a workpiece. The shape of the cutting edge determines the shape that will be formed on the workpiece.

- Dull Tool: This tool enlarges an already drilled hole. It’s often used to finish holes to specific sizes or to create internal grooves.

- Parting-off Tool: This tool cuts off a portion of the workpiece from the rest of the part. It’s often used at the end of a turning operation to separate the finished part from the remaining stock.

- Counterboring Tool: This tool enlarges the end of a hole to a specific diameter and depth. It’s often used to create a bolt head or nut recess.

- Undercutting Tool: This tool is used to cut away the underside of a workpiece. It’s often utilized to create a specific feature or to prepare a part for a subsequent operation.

Specific Applications of Each Tool

Turning Tool: Used in general machining operations to create cylindrical parts.

Chamfering Tool: Used to prepare parts for threading or to remove sharp edges.

Thread Cutting Tool: Used in the creation of threaded parts, such as bolts and screws.

Facing Tool: Used to create flat surfaces on the ends of parts.

Grooving Tool: This tool creates grooves or recesses in parts, often to house seals or o-rings.

Forming Tool: This tool is Used to create complex shapes on parts, often in producing decorative items or components with specific functional requirements.

Dull Tool: Used to finish holes to specific sizes or to create internal grooves.

Parting-off Tool: Used to separate a finished part from the remaining stock.

Counterboring Tool: Used to create recesses for bolt heads or nuts.

Undercutting Tool: This tool is Used to create specific features on a part or to prepare a part for a subsequent operation.

The Role of Lathe Cutting Tools in CNC Lathe Machines

Lathe-cutting tools play a crucial role in the functionality of CNC lathe machines. These tools are mounted on the lathe machine and move along the lathe’s axis, determining the final shape of the workpiece. Modern CNC lathe machines usually have tools that can work on multiple axes, allowing more complex parts to be produced without manually switching machines or tools. This means a CNC lathe can perform additional milling, drilling, and tapping operations, resulting in a complete and even complex part manufacturing process and eliminating the need to transfer the part to another machine for a second operation.

How Lathe Cutting Tools Contribute to the Functionality of CNC Lathe Machines

The role of the tool on the CNC lathe is akin to the effect of the wheel on the car. The material used to make the tool must have high-temperature hardness and wear resistance, necessary bending strength, impact toughness, chemical inertness, good processability (cutting, forging, heat treatment, etc.), and not easily deformed. Good tools can increase the machining efficiency and accuracy of the cut workpiece.

The Impact of Lathe Cutting Tools on the Precision and Efficiency of CNC Lathe Machines

The appropriate selection of cutting tools will significantly impact the efficiency and quality of the final product. The right cutting tool can improve the efficiency and precision of the machining process, reduce the time taken, and ultimately impact the quality of the final product. Therefore, understanding the different types of lathe-cutting tools and their applications is essential for anyone involved in machining operations.

Case Study: Application of Different Lathe Cutting Tools in Real-world CNC Lathe Projects

In CNC machining, lathe-cutting tools are essential for shaping and creating parts with precision and efficiency. Drawing from the latest insights and applications, here are examples of how different lathe-cutting tools are used in various CNC lathe projects.

Turning Tools:

- Application: Turning tools are fundamental in reducing the diameter of cylindrical workpieces, such as when creating shafts or spindles.

- Real-world Example: In automotive manufacturing, turning tools shape camshafts and crankshafts, ensuring they fit within the precise specifications required for engine performance.

Boring Tools:

- Application: Boring tools enlarge pre-drilled holes to precise dimensions or create internal shapes within a workpiece.

- Real-world Example: Boring tools are used in the aerospace industry to refine the holes in jet engine components, where tight tolerances are critical for safety and performance.

Facing Tools:

- Application: Facing tools create a flat surface perpendicular to the workpiece’s rotational axis, essential for parts with a flat end surface.

- Real-world Example: Facing tools are commonly used to prepare the ends of hydraulic cylinder components, ensuring they seal correctly and operate smoothly.

Chamfering Tools:

- Application: Chamfering tools create beveled edges on workpieces, which can be necessary for functional purposes, such as easing assembly and aesthetic reasons.

- Real-world Example: Chamfering tools bevel the edges of gears, allowing for smoother engagement and reducing the risk of gear teeth chipping.

Knurling Tools:

- Application: Knurling tools create a textured pattern on the surface of a workpiece, often for improved grip or decorative purposes.

- Real-world Example: Knurling tools are used to texture the handles of surgical tools, providing surgeons with a better grip during procedures.

Parting Tools:

- Application: Parting tools are used to cut off a finished part from the rest of the stock material and for grooving operations.

- Real-world Example: In producing valves, parting tools separate the valve components from the bar stock once they have been machined to the correct size.

Forming Tools:

- Application: Forming tools combine the capabilities of turning and grooving tools to create complex shapes in a single pass, which is more accurate and production-efficient.

- Real-world Example: Forming tools create intricate profiles on brass instrument components, such as trumpet valves, where precision is critical to the instrument’s performance.

Thread Cutting Tools:

- Application: Thread-cutting tools are used for creating internal and external threads on parts, which is essential for components that must be assembled with screws or bolts.

- Real-world Example: Thread-cutting tools are used in the manufacture of bone screws in medical implants, where precise threading is crucial for the screws to function correctly in the human body.

Grooving Tools:

- Application: Grooving tools create grooves on cylindrical surfaces, which can be functional for o-ring placement or aesthetics.

- Real-world Example: Grooving tools are used in the production.

What to Consider When Choosing a Lathe Tool

Choosing the right lathe tool is a critical step in ensuring the success of your machining operations. Here are some key factors to consider:

Workpiece Material and Properties: The composition of the workpiece plays a significant role in selecting the lathe tool. The tool material must be more complex and durable for efficient machining than the workpiece. For example, machining hard materials like titanium may require tools of more brutal substances, such as diamond.

Desired Surface Finish and Tolerances: The required surface finish and tolerance will influence the properties of the lathe tool. Metal lathe tools with high rake angles and sharp cutting edges are preferable for a smooth surface finish. On the other hand, achieving tight tolerances may require using dimensionally stable materials like carbide.

Tool Geometry: The overall geometry of the lathe cutting tool impacts the cutting performance and tool wear. Tool geometries designed to optimize chip flow and minimize cutting forces can extend tool life and improve surface finish.

Tool Material: The material of the tool is another important consideration. Options include high-speed steel (HSS), carbide, ceramic, and diamond. The choice depends on the workpiece’s material, the operation speed, and the tool’s desired lifespan.

Tool Size and Compatibility: The tool must be compatible with your lathe machine and holder. This includes considering its size and mounting style.

Operation Type: Different operations require specific tool types. For instance, turning, facing, threading, and grooving each need different tools.

Speed and Feed Rates: The cutting speed and feed rate can impact the tool material and geometry choice. Higher speeds may require more complex materials or specific coatings to maintain tool integrity.

Cost: While opting for the cheapest tool may be tempting, it’s essential to consider the tool’s lifespan and performance. A more expensive tool may offer better longevity and performance, saving costs over time.

Safety: Always ensure that the tool and holder are adequately secured and that the tool is suitable for the speeds and feeds of the operation to prevent accidents.

Manufacturer’s Recommendations: Always refer to the manufacturer’s recommendations for tool selection based on the lathe machine and materials used.

Meeting Modern Machining Needs with LongSheng Solutions

Are you looking for a reliable and reputable partner for your lathe tools machining needs or custom machined parts? Choose LongSheng for a top-quality experience. Upload your CAD file on our online quotation platform and get instant quotations with an automated DfM report. Furthermore, you can also manage and track your order until delivery!

At LongSheng, we deliver quality manufacturing solutions to our clients by leveraging innovative technology and experienced teams. Our team of engineers has extensive knowledge about machining tools, and our recurring use of these tools puts us at the forefront of custom machining.

Conclusion

As the primary contact point between the machine and the workpiece, lathe-cutting tools are indispensable in CNC machining. They shape materials through various operations such as turning, facing, boring, chamfering, and threading. The material and geometry of these tools are critical factors that influence the cut’s quality and the lathe machine’s efficiency. Different types of lathe-cutting tools are designed for specific purposes, ensuring that various machining requirements can be met across aerospace, automotive, and medical industries.

Selecting the suitable cutting tool material, such as High-speed Steel (HSS), Carbide, Diamond, or Cubic Boron Nitride, is essential for efficient machining, as the tool must be more complex and durable than the workpiece. The tool’s structure, whether single-body, welded, or clamped, along with the feed direction, plays a significant role in determining the direction of material removal and the surface finish.

Future Trends in the Development of Lathe Cutting Tools for CNC Lathe Machines

The continuous pursuit of precision, efficiency, and versatility shapes the future of lathe-cutting tools. Advancements in materials and geometries are expected to improve their performance further. Coating technologies like Titanium Nitride (TiN), Titanium Carbide (TiC), and Aluminum Oxide are being developed to extend tool life and enhance performance.

In addition to material improvements, integrating advanced technologies such as AI, machine learning, and real-time monitoring systems is anticipated to revolutionize the design and optimization of lathe-cutting tools. These intelligent tools will be equipped with sensors and adaptive control systems, enabling them to adjust to varying conditions and maintain high precision throughout the machining process.

Automation and digitalization in CNC machining also drive the development of lathe-cutting tools. Trends point towards high-speed machining, functional composite machine tools, and intelligent control systems. The industry also focuses on greening manufacturing processes, making energy-saving and environmentally friendly machine tools increasingly important.

The role of a lathe tool setter is becoming more prominent, as it ensures consistent and accurate tool positioning, which is vital for maintaining tight tolerances and high-quality results. This technology helps detect tool wear and automatically updates tool offsets, reducing scrap and improving part quality.

In conclusion, lathe-cutting tools are at the heart of CNC lathe machines, and their development is crucial for advancing manufacturing processes. The ongoing innovations in tool materials, geometries, coatings, and digital technologies are set to enhance the capabilities of CNC lathes, ensuring that they can meet the evolving demands of modern industries with precision and efficiency.

FAQs

1. What is a lathe machine?

A lathe machine, also known as the Mother of all Machines, is a versatile machine that dates back to the 13th century. It is used to shape materials like metals and wood. The machine operates by holding and rotating the workpiece while stationary cutting tools mounted on the lathe remove parts of the rotating workpiece. This leaves behind a shaped workpiece according to the product design.

2. What are lathe cutting tools?

Lathe-cutting tools are mounted on a lathe and used to produce turned parts. They move along the lathe’s axis, and their path determines the workpiece’s final shape. These tools are pivotal parts of CNC machining services and are instrumental in producing turned parts with a lathe machine and shaping materials to the desired form.

3. What are the different types of lathe-cutting tools?

Lathe-cutting tools can be classified according to materials, operations, structure, and feed direction. Some common types include turning tools, boring tools, facing tools, chamfering tools, knurling tools, parting tools, forming tools, thread-cutting tools, and grooving tools. Each type has unique features and designs determining the supported lathe-cutting operation and applications.

4. How do I choose the right lathe-cutting tool?

Choosing the right lathe-cutting tool requires an in-depth understanding of the tool. Factors to consider include the material to be machined, the tool material, the desired surface finish and tolerances, the tool geometry, the type of operation, the speed and feed rates, the tool size and compatibility, the cost, and safety considerations. It’s also essential to refer to the manufacturer’s recommendations for tool selection based on the specific lathe machine and materials being used.

5. Can a CNC lathe perform additional operations apart from turning?

Modern CNC lathe machines usually have tools that can work on multiple axes. This means a CNC lathe can perform additional milling, drilling, and tapping operations, resulting in a complete and even complex part manufacturing process and eliminating the need to transfer the part to another machine for a second operation.

6. How does the choice of lathe-cutting tools affect the success of a CNC lathe project?

The success of your CNC lathe project depends on your choice of lathe-cutting tools. The right tool can ensure optimal performance, longevity, and quality of the finished product. Therefore, working with a machine shop with highly qualified engineers and machinists capable of understanding your design and choosing the ideal tools and machining parameters is essential.

Pingback: How to Choose the Right CNC Machining Supplier? - LONGSHENG

Pingback: How to Estimate CNC Machining Costs?

Pingback: What Information Is Needed for a CNC Machining Quote?

Pingback: How to Negotiate CNC Machining Quotes?

Pingback: CNC Machining Comparison: How to Evaluate Services Through Reviews & Head-to-Head Analysis

Excellent website. A lot of helpful info here. I am sending it to several friends ans additionally sharing in delicious. And certainly, thank you for your sweat!

Thank you for your attention, please subscribe to us and share valuable information with your friends in need, have any needs, please send us an inquiry.

I believe that is one of the so much significant info for me. And i’m happy studying your article. But wanna remark on some normal issues, The web site taste is perfect, the articles is truly excellent : D. Excellent activity, cheers

Thank you for your support, each article is written by ourselves, we will update the article every day, you can subscription LS, wish you a happy day.

I think this site has some real fantastic information for everyone. “Variety is the soul of pleasure.” by Aphra Behn.