The use of plastic injection molding has become increasingly popular in different sectors of the industry. From the automobile industry to the packaging industry, this technology is transforming the way we produce various products.When you think of plastic products, do you ever wonder how they’re made? One common manufacturing process is plastic injection molding. In this article, we’ll explore what plastic injection molding is, how it works, and its benefits.

What is Plastic Injection Molding?

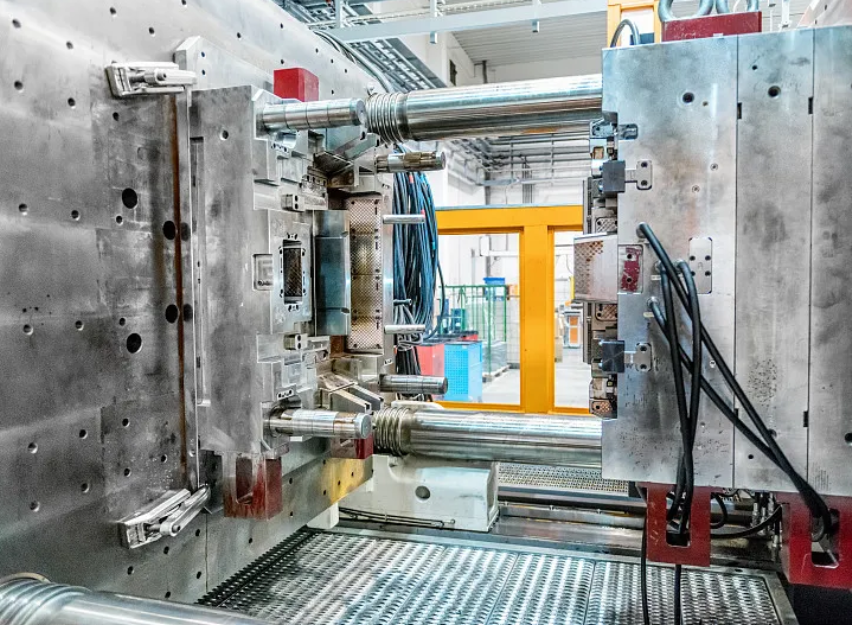

Plastic injection molding is a manufacturing process that involves melting plastic pellets and injecting them into a mold. Once the molten plastic cools and hardens, the mold is opened, and the finished product is ejected. The process can be used to create a wide variety of plastic products of different shapes and sizes, from complex automotive parts to simple plastic toys.

But, what are the advantages that made this technology so popular and transformative? Injection molding can produce components that are extremely consistent, repeatable and have a great surface finish. Additionally, it creates minimal scrap and virtually has no limit to the size and geometry of the final part.

Another key benefit of injection molding is its speed-to-market capability. The tooling used in injection molding is unique and especially designed to meet the customer’s requirements, ensuring repetitive quality.

It’s important to mention some of the interesting facts regarding this technology too. Did you know that the injection molding process began in the 1870s? Yes, it’s true! The first injection molding machine was invented by Hyatt brothers and introduced in the USA. It’s also possible to create parts with multiple layers, composite material and fillers.

In more recent times, injection molding technology has embraced what is known as Industry 4.0. Smart sensors & IoT devices are being integrated in the machines, providing data in real-time to maximize uptime, lower maintenance costs and improve part quality.

Now that you have a better understanding of what plastic injection molding is and the key advantages, It’s easy to see why it is the preferred manufacturing process for so many industries such as automotive, medical devices, household appliances, and many more.

Why Choosing Plastic Injection Molding is No Longer an Option But a Necessity?

Plastic injection molding has become an essential component of modern manufacturing. In recent years, the industry has seen rapid growth, with plastic injection molding machines producing millions of parts each day. As such, it is no longer an option but a necessity for businesses to choose plastic injection molding for their manufacturing needs.

Why is Plastic Injection Molding a Necessity?

Plastic injection molding is a versatile and efficient manufacturing process that produces high-quality, complex parts at a low cost. The process is fast and automated, allowing manufacturers to produce large quantities of parts in a short amount of time.

Furthermore, plastic injection molding uses a wide range of materials, including thermoplastics and thermosetting plastics, to produce parts that are resilient, lightweight, and durable. These materials can be used in a wide range of products, from car parts to medical devices, consumer goods to industrial equipment.

The advantages of plastic injection molding go beyond the manufacturing process itself. It is an environmentally friendly process that reduces waste and energy consumption, making it a sustainable and responsible option for businesses.

Why is Choosing Plastic Injection Molding a Necessity?

With the rise of consumer demand for high-quality, durable products, businesses must choose the most efficient and effective manufacturing process possible. Plastic injection molding is the only viable option for producing complex parts at a low cost and high volume.

Choosing plastic injection molding allows businesses to produce high-quality parts that meet consumer demands while reducing manufacturing costs. This enables businesses to remain competitive in the market while maintaining profit margins.

Furthermore, plastic injection molding enables businesses to reduce lead times and improve production efficiency, leading to faster production rates and improved customer satisfaction.

in a rapidly changing manufacturing landscape, choosing plastic injection molding is no longer an option, but a necessity. Its versatility, efficiency, and sustainability make it the only viable option for businesses looking to remain competitive and meet consumer demands. So, if you want to stay ahead of the game, consider plastic injection molding for your next manufacturing project.

How does Plastic Injection Molding work?

When it comes to manufacturing plastic products on a large scale, nothing beats plastic injection molding. It’s an efficient process that produces high-quality parts with unmatched speed and precision. If you’re curious about how it works, then keep reading.

Plastic injection molding involves melting plastic pellets in a hopper, then injecting the melted plastic into a mold. The mold is created to match the exact specifications of the part that needs to be produced. The plastic is then left to cool and solidify inside the mold, and finally, the finished product is ejected.

What makes this process so unique is that it allows for intricate designs and shapes to be produced quickly and efficiently. Additionally, the use of molds allows for consistent product quality and minimal waste. This makes it an excellent option for large-scale productions.

If you’re still undecided about whether plastic injection molding is the right fit for your project, then consider these benefits:

1) Cost-effective – Plastic injection molding is one of the most cost-effective manufacturing methods available. It’s perfect for mass-production, where the cost per part is significantly reduced.

2) Fast turnaround time – The process of plastic injection molding is incredibly fast, with molds being produced within a day or two. This allows for quick turnaround times compared to other manufacturing processes.

3) Versatile – Plastic injection molding can be used to produce a vast range of products, from small plastic parts to large industrial parts.

4) Durable – Plastic injection molding creates products that are durable and long-lasting, which is essential for products that need to withstand wear and tear.

In conclusion, plastic injection molding is a fast, cost-effective, and versatile method of manufacturing plastic products. With consistent product quality and minimal waste, it’s an excellent option for any large-scale production. So, if you’re looking for a manufacturing process that produces high-quality parts at a reasonable price, then plastic injection molding is an excellent choice.

Applications of Plastic Injection Molding

Plastic injection molding has become an integral part of modern manufacturing processes and has influenced various industries. The applications of plastic injection molding are numerous and continue to expand as technology improves. In this article, we’ll discuss the various applications of plastic injection molding, the benefits of these applications, and why you should consider using plastic injection molding for your manufacturing processes.

Plastic injection molding finds its application in producing high-quality products across various industries, including healthcare, automotive, packaging, consumer products, and many others. Injection molding has revolutionized the manufacturing process by making it faster, cheaper, and more efficient.

One of the significant benefits of plastic injection molding in the healthcare industry is that it provides a way to mass-produce medical devices quickly and efficiently while maintaining quality and accuracy. Healthcare professionals rely on medical devices for treatment, diagnosis, and monitoring, and injection molding technology allows for precise manufacturing of these critical components.

In the automotive industry, plastic injection molding is used to manufacture various car parts that are crucial for vehicle safety, such as dashboards, bumpers, and car seats. The process allows for the creation of lightweight parts that are durable and resistant to wear and tear. This technology boosts vehicle performance, enhances safety, and reduces production costs.

Packaging is another industry that benefits significantly from plastic injection molding. The process allows manufacturers to produce packaging materials that are durable, lightweight, and cost-effective. Injection molding technology provides a way to produce high-quality packaging solutions that can withstand extreme temperatures, corrosive materials, and other harsh environments.

Plastic injection molding has also transformed the consumer products industry. Manufacturers use the process to create household products like toys, appliances, and kitchenware. The technology allows for the production of high-quality products that are durable, safe, and affordable.

In conclusion, plastic injection molding is a cost-effective and efficient manufacturing process that has various applications across different industries. By adopting this technology, manufacturers can produce high-quality products that meet customer demands while reducing costs and enhancing productivity. If you haven’t considered plastic injection molding for your manufacturing process, it’s time to explore its benefits and see how it can help your business grow.

FAQ

The size range of parts that can be produced varies depending on the specific machine and mold used. Typically, parts can range from small and intricate to large and complex.

Almost any type of thermoplastic polymer can be used, including ABS, polycarbonate, nylon, and polypropylene.

The process can take anywhere from a few seconds to a few minutes, depending on the size and complexity of the part.