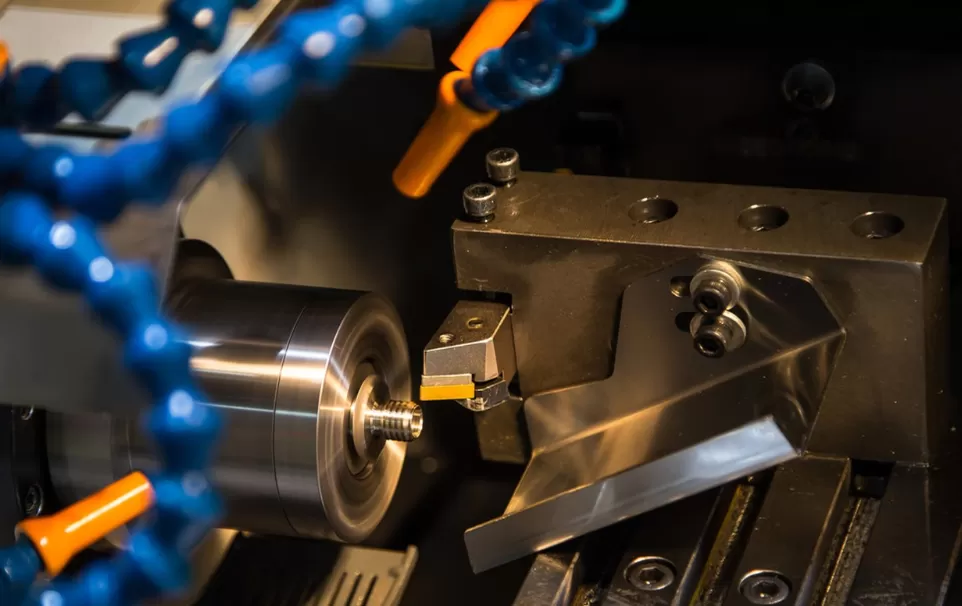

CNC turning is a manufacturing process that uses computer numerical control (CNC) machines to shape and cut materials into specific shapes and sizes. This process has several advantages over traditional turning methods, which rely on manual labor and machinery. In this article, we will discuss the advantages of CNC turning and how it can benefit both manufacturers and customers.

- Precision

One of the main advantages of CNC turning is its precision. CNC machines are programmed to cut materials with a high degree of accuracy and consistency, which results in parts that are identical in shape and size. This level of precision is difficult to achieve with traditional turning methods, which rely on manual measurements and adjustments.

- Speed

CNC turning is also faster than traditional turning methods. CNC machines can produce parts at a much faster rate than manual machines, which means that manufacturers can produce more parts in less time. This is especially important for high-volume production runs, where efficiency and speed are critical.

- Flexibility

CNC turning machines are highly flexible and can be programmed to produce a wide range of parts and shapes. This means that manufacturers can easily switch between different production runs and make changes to the design without the need for new tools or equipment. This flexibility allows manufacturers to respond quickly to changing customer demands and market trends.

- Consistency

Another advantage of CNC turning is its consistency. Because CNC machines are programmed to produce the same parts repeatedly, the parts are consistent in quality and performance. This is important for manufacturers who need to produce parts that meet strict quality standards and specifications.

- Cost savings

CNC turning can also save manufacturers money in the long run. While CNC machines may be more expensive to purchase and maintain than traditional machines, they can produce parts at a lower cost per unit. This is because CNC machines are more efficient and require less manual labor, which reduces the overall cost of production.

In conclusion, CNC turning offers several advantages over traditional turning methods, including precision, speed, flexibility, consistency, and cost savings. These benefits make CNC turning an excellent choice for manufacturers who need to produce high-quality parts quickly and efficiently. Additionally, customers can benefit from the precision and consistency of CNC turning, which can result in better-performing products and lower costs.

As an international high -end OEM/ODM manufacturer, Longsheng has nearly 20 years of development experience. Our core manufacturing services include:CNC machining parts service,CNC Turning Machine Parts,Sheet Metal Machining Parts,Customized Extrusion Moulding Parts,Die Casting Services,3d printing Services,squeezing and stamping. We also expand our capabilities to mold manufacturing, injection molding services, 3D metal and plastic printing and complete traffic key items