Aluminum Fabrication: A Complete Evaluation of Aluminum Sorts and Manufacturing Processes

Aluminum fabrication is a exact process involving changing aluminum into elements of varied sizes and shapes, utilizing an array of numerous strategies and procedures. Aluminum, on account of its light-weight, excessive power, ease of machining, and corrosion resistance, has develop into the popular materials in sectors corresponding to aerospace, automotive manufacturing, development, and electronics.

The first strategies of aluminum fabrication embody extrusion, drawing, forming, casting, and forging. Extrusion entails forcing aluminum by or round a die to evolve to its form and dimension. Drawing pulls aluminum by a tapered die to stretch it. Forming presses all or part of the aluminum into the specified closing product. Casting entails pouring liquid aluminum right into a mold or die, whereas forging shapes aluminum by hammering or compressing it.

Concerning the varieties of aluminum, there are primarily three:

Wrought Aluminum and Aluminum Alloys: These are fashioned by processes corresponding to extrusion, rolling, or forging. These processes are employed to type billets, rods, and ingots wanted for different manufacturing processes like machining. Wrought aluminum and its alloys are broadly utilized in numerous industries, together with automotive, aerospace, medical, and shopper product industries.

Anodized Aluminum: That is aluminum or an aluminum alloy whose floor has been hardened and made extra sturdy by electrochemical reactions. Anodizing aluminum enhances its resistance to put on and corrosion, making it appropriate for a wide range of purposes.

Aluminum Sheet Metal: That is generally utilized in fabrication processes. Sheet metallic may be minimize, bent, or stretched into almost any form after which joined to create a product. Aluminum sheet metallic fabrication is among the extra widespread strategies in manufacturing, utilized in making vehicles, cans, computer systems, home equipment, airplanes, and numerous instruments.

On this information, you’ll acquire a deeper understanding of the assorted strategies and processes of aluminum fabrication, in addition to the differing types and purposes of aluminum. We are going to take you on a journey into the fascinating world of aluminum fabrication, presenting advanced subjects in a digestible method.

Introduction to Aluminum

Aluminum is a broadly used metallic materials, famend for its light-weight, excessive power, simple machining, and glorious corrosion resistance. These traits make aluminum a really perfect selection throughout numerous fields corresponding to aerospace, automotive manufacturing, development, and electronics.

Classes of Aluminum

Aluminum is primarily divided into the next classes:

| Class | Description |

|---|---|

| Pure Aluminum | Pure aluminum boasts good electrical and thermal conductivity, making it a standard selection in fields corresponding to energy, electronics, and warmth exchangers. |

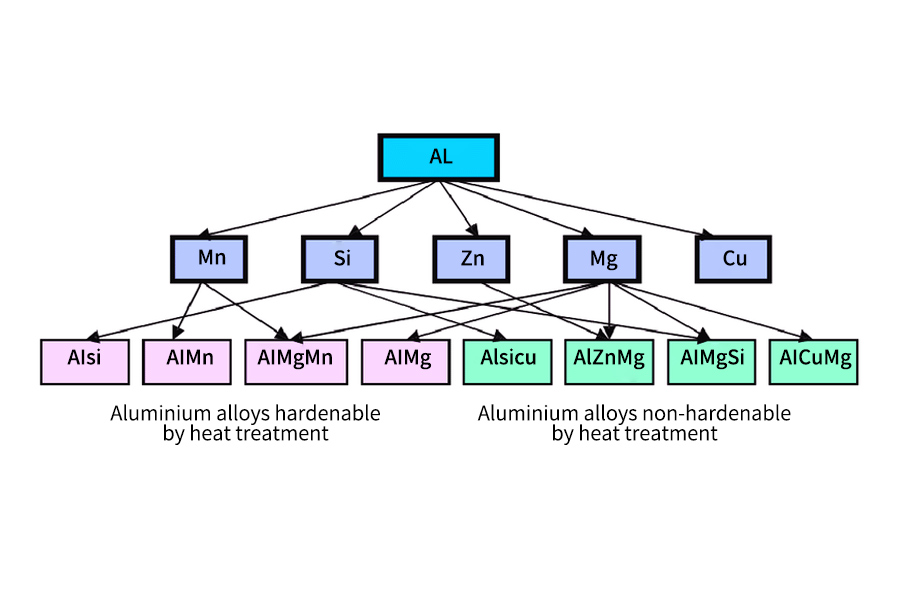

| Aluminum Alloy | Aluminum alloy is created by including different components (corresponding to copper, manganese, silicon, magnesium, and so forth.) to aluminum to reinforce its power and hardness. Aluminum alloys are extensively used within the automotive, aerospace, and development industries. |

| Cast Aluminum | Cast aluminum is an aluminum product made by the casting process. It has good fluidity and plasticity, making it appropriate for parts with advanced shapes. |

Aluminum Fabrication Process

The aluminum fabrication process covers all of the steps from uncooked aluminum to the ultimate elements. The generally used aluminum fabrication strategies embody casting, forging, extrusion, rolling, stamping, welding, and so forth. The next desk outlines the traits, benefits, disadvantages, and utility ranges of those processes:

| Fabrication Process | Traits | Advantages | Disadvantages | Software Vary |

|---|---|---|---|---|

| Casting | Merchandise are made by pouring liquid aluminum right into a mold | Can manufacture advanced parts, low price | Decrease precision, might have inside porosity or inclusions | Advanced parts corresponding to engine elements |

| Forging | Aluminum is formed by strain | Excessive power, wear-resistant | Excessive price, form limitations | Excessive power parts, corresponding to aerospace elements |

| Extrusion | Aluminum is extruded by a mold to create numerous shapes | Can manufacture numerous shapes, excessive precision | Excessive tools price | Numerous shapes of parts, corresponding to window frames, pipes |

| Rolling | Aluminum is pressed into sheets or rods by strain | Can manufacture sheets or rods, excessive precision | Form limitations, excessive tools price | Sheets or rods, corresponding to aluminum foil, automotive sheet metallic |

| Stamping | Aluminum is stamped into numerous shapes utilizing a mold | Excessive manufacturing effectivity, excessive precision | Excessive mold price, solely relevant to skinny plates | Skinny plate elements, corresponding to automotive parts, digital parts |

| Welding | Aluminum parts are joined collectively utilizing warmth or strain | Can join parts of varied shapes | Requires specialised tools and expertise | Structural parts, corresponding to bridges, vessels |

Three Frequent Types of Aluminum Materials

Aluminum, on account of its lightness, excessive power, ease of processing, and glorious corrosion resistance, is broadly utilized in numerous fields. Listed below are three widespread types of aluminum, together with their traits and purposes:

Aluminum Plate: An aluminum plate is a plate-shaped materials made by rolling aluminum alloy, with thickness often between 0.5mm and 10mm. Its light-weight and corrosion resistance make it a really perfect selection for manufacturing plane skins, automotive physique parts, development supplies, and so forth. As well as, aluminum plates are sometimes used to fabricate numerous family home equipment, corresponding to fridges, air conditioners, and so forth., due to their glorious thermal conductivity, which may successfully dissipate warmth.

Aluminum Profile: Aluminum profile is a wide range of formed aluminum alloy supplies produced by extrusion or rolling processes, with cross-sections that may be round, sq., rectangular, special-shaped, and so forth. This type of aluminum has extraordinarily excessive flexibility and may manufacture merchandise of varied sizes and shapes as wanted. Subsequently, aluminum profiles are broadly used within the manufacture of doorways and home windows, frames, structural parts, and so forth. As well as, aluminum profiles are sometimes used to fabricate casings for digital units, corresponding to computer systems, cellphones, and so forth., as their good thermal conductivity will help the tools dissipate warmth.

Aluminum Rod: An aluminum rod is a cylindrical or sq. materials made by forging or rolling aluminum alloy, with a diameter or facet size sometimes between 5mm and 500mm. The excessive power and put on resistance of aluminum rods make them a really perfect selection for manufacturing mechanical parts corresponding to bearings, pistons, gears, and so forth. As well as, aluminum rods are sometimes used to fabricate energy tools, corresponding to transformers, motors, and so forth., as a result of their good electrical conductivity can improve the working effectivity of the tools.

High quality Management in Aluminum Manufacturing

High quality management is an important facet within the process of aluminum manufacturing. Listed below are some main high quality management measures and detection strategies:

Uncooked Materials Inspection: High quality management begins from the supply, making certain that the aluminum uncooked supplies used adjust to related requirements and specs.

process Management: Strict adherence to the process movement to keep away from high quality points brought on by improper operations.

Tools Upkeep: Common upkeep and calibration of apparatus to make sure their regular operation.

On-line Inspection: Conduct on-line inspection throughout the manufacturing process to well timed determine and resolve points.

Closing Product Inspection: Complete efficiency and dimensional inspection of the ultimate merchandise to make sure they meet high quality necessities.

The strategies to detect the properties and defects of aluminum primarily embody hardness testing, tensile testing, impression testing, metallographic evaluation, ultrasonic testing, radiographic testing, and so forth.

Requirements and specs to make sure the standard of aluminum merchandise primarily embody nationwide requirements (GB), trade requirements (JB), enterprise requirements (Q/), and worldwide requirements (ISO).

Future Developments in Aluminum Manufacturing

With the development of expertise and modifications in social calls for, aluminum manufacturing can also be welcoming some new improvement tendencies:

Growth of New Aluminum Alloy Materials: With the event of latest materials science, extra new varieties of aluminum alloys might be developed sooner or later. These new aluminum alloys can have superior efficiency, corresponding to greater power, higher corrosion resistance, decrease density, and so forth., to satisfy the wants of varied high-end purposes.

Software of Clever Aluminum Manufacturing Know-how: With the event of Trade 4.0 and 5.0, clever manufacturing applied sciences might be extra broadly utilized in aluminum manufacturing. For instance, by the Web of Issues, huge knowledge, synthetic intelligence, and so forth., the automation and intelligence of the aluminum manufacturing process may be achieved, bettering manufacturing effectivity, decreasing manufacturing prices, and in addition bettering product high quality.

Promotion of Inexperienced and Environmental Aluminum Manufacturing Ideas: With the society’s elevated consciousness of environmental safety, the idea of inexperienced and environmental aluminum manufacturing might be extra broadly promoted. For instance, by adopting extra environmentally pleasant manufacturing processes, utilizing recyclable aluminum, decreasing waste emissions within the manufacturing process, and so forth., the greening and environmental safety of aluminum manufacturing may be achieved.

Why select LongSheng?

As for why one may select LongSheng manufacturing facility, it is as a result of they focus on customized aluminum parts and excel in creating cupboards, enclosures, brackets, and complicated assemblies. Their providers embody design, mass manufacturing, floor remedy, and meeting. With over 20,000 initiatives accomplished for greater than 3,500 international patrons, they’ve demonstrated their capabilities and reliability.Conclusion

Aluminum fabrication entails shaping aluminum or its alloys into particular types or merchandise utilizing strategies corresponding to extrusion, drawing, forming, casting, and machining. The three widespread types of aluminum utilized in manufacturing are aluminum sheet/plate, aluminum extrusions/profiles, and aluminum rods/billets. These types are broadly utilized in numerous industries on account of their light-weight, corrosion resistance, and flexibility. Selecting LongSheng manufacturing facility for aluminum fabrication may be advantageous as they focus on customized aluminum parts, providing providers corresponding to design, mass manufacturing, floor remedy, and meeting. With a observe report of over 20,000 initiatives accomplished for greater than 3,500 international patrons, LongSheng has demonstrated its capabilities and reliability within the area of aluminum fabrication.FAQs

What’s the commonest aluminum?

In every day life and industrial manufacturing, the commonest varieties of aluminum are pure aluminum and aluminum alloys. Pure aluminum is principally used within the energy trade, corresponding to for wires, cables, and so forth. Aluminum alloys, on account of their excessive power, mild weight, and corrosion resistance, are broadly utilized in industries corresponding to aviation, automotive, and development.

What are the three makes use of of aluminum?

- Energy Trade: Aluminum is a serious materials within the energy trade, used to fabricate wires, cables, energy transformers, and so forth.

- Transportation: Aluminum alloys, on account of their light-weight, excessive power, and corrosion resistance, are broadly used within the manufacture of automobiles corresponding to vehicles, airplanes, and trains.

- Building Trade: Aluminum and its alloys are broadly used within the development trade, corresponding to for window frames, doorways, curtain partitions, and so forth.

Which kind of aluminum is greatest?

The “greatest” kind of aluminum is dependent upon its use case. As an illustration, in case you want a cloth that’s light-weight and high-strength, aluminum alloys (like 6061, 7075, and so forth.) can be a sensible choice. In the event you want glorious electrical conductivity, pure aluminum can be a better option. Subsequently, selecting the suitable kind of aluminum based mostly on particular utility necessities is crucial.