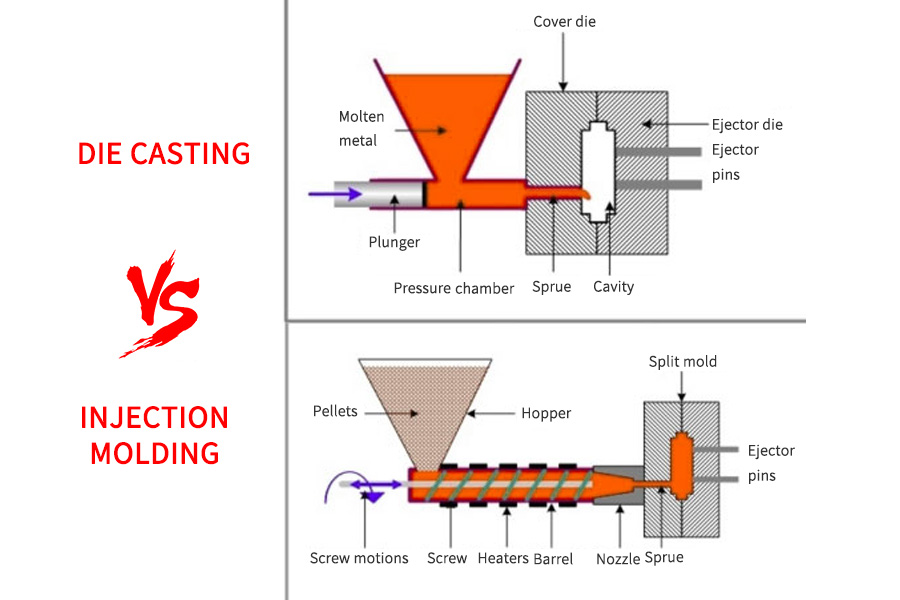

Casting and molding are two necessary manufacturing processes that play an important function within the manufacturing of assorted merchandise and elements. Casting sometimes includes pouring molten materials right into a pre-made mold, then cooling and solidifying to form the specified form. This methodology is appropriate for a wide range of materials, together with metals and plastics, and is especially well-suited for producing advanced shapes and enormous parts.

Molding, however, is a process of shaping materials into a selected form by making use of strain and warmth. This methodology is usually used for plastics and rubber and might produce a lot of an identical parts shortly. A significant benefit of molding is the power to exactly management the scale and floor high quality of the product.

The principle variations between the 2 lie within the manufacturing process, the kinds of materials used, cost-effectiveness, and the standard and precision of the ultimate product. Casting is appropriate for producing massive or complex-shaped parts, whereas molding is extra acceptable for mass manufacturing of standardized merchandise. Every process has its benefits, and the selection between them relies on the particular manufacturing necessities and aims.

The principle physique will additional discover the technical particulars, software instances, and the way to decide on the suitable manufacturing methodology based mostly on venture necessities in additional element.

Casting Vs Molding

Clear definition of casting and molding ideas,Clarify the respective traits of casting and molding| Function | Casting | Molding |

|---|---|---|

| Definition | Pouring liquid materials right into a mold to form a hard and fast form upon cooling | Shaping materials into a selected form by making use of strain and warmth |

| Relevant Materials | Metals, plastics, glass, and many others. | Plastics, rubber, and different pliable materials |

| Complexity of Shapes | Able to manufacturing parts with advanced shapes | Appropriate for producing parts with standardized shapes |

| Price-Effectiveness | Extra economical for large-scale manufacturing | Could also be extra economical for small-scale manufacturing |

| Measurement Limitations | Appropriate for giant parts | Appropriate for small to medium-sized parts |

| Manufacturing Velocity | Slower, relies on cooling time | Sooner, appropriate for fast manufacturing |

| Precision and High quality | Depends upon the standard of the mold | Excessive precision, constant product high quality |

Casting Vs Molding

Materials: Evaluate the totally different materials utilized in casting and molding Process: Detailed description of the process circulation of casting and molding Advantages and drawbacks: Enumerate the benefits and drawbacks of casting and molding| Function | Casting | Molding |

|---|---|---|

| Materials | Metals (iron, steel, aluminum), plastics, glass | Plastics (polymers), rubber |

| Process Movement | 1. Mould design 2. Put together molten materials 3. Pouring 4. Cooling and solidification 5. Half removing 6. Submit-processing | 1. Mould design 2. Materials choice 3. Heating and urgent 4. Cooling 5. Half removing 6. Submit-processing |

| Advantages | – Can produce advanced shapes – Appropriate for giant parts – Numerous materials decisions | – Quick manufacturing pace – Excessive repeatability – Excessive precision – Low vitality consumption |

| Disadvantages | – Gradual manufacturing pace – Excessive vitality consumption – Excessive demand for post-processing | – Tough design adjustments – Excessive preliminary funding – Restricted complexity of shapes |

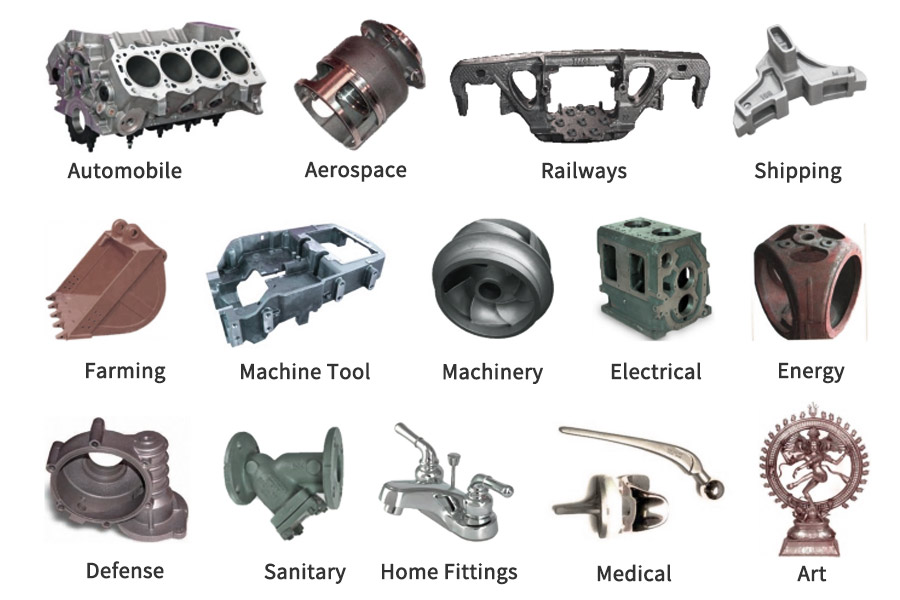

Software Fields of Casting:

- Automotive Business: Casting is used to fabricate engine parts, gearbox housings, wheel hubs, and many others.

- Aerospace: Casting is employed in producing plane engine elements, fuselage structural parts, and extra.

- Building: Casting is used to create architectural structural elements corresponding to rebar, door and window frames, and many others.

- Equipment Manufacturing: Casting is utilized for producing numerous mechanical parts like pumps, valves, gears, and many others.

Software Fields of Molding:

- Client Electronics: Molding is used to make mobile phone instances, pc casings, keyboard keys, and many others.

- Medical Gear: Molding is used for producing disposable syringes, take a look at tubes, medical containers, and extra.

- Toy Manufacturing: Molding is utilized in producing numerous plastic toys corresponding to constructing blocks, dolls, plastic automobiles, and many others.

- Packaging Business: Molding is used to fabricate numerous plastic packaging merchandise like bottle caps, containers, trays, and many others.

These software fields exhibit the huge applicability and suppleness of casting and molding in manufacturing totally different merchandise. Every process has its distinctive benefits that may meet the wants of particular product manufacturing. The selection of the suitable process relies upon not solely on the useful and design necessities of the product but additionally on cost-effectiveness and manufacturing effectivity.

Conclusion

Casting and molding are manufacturing processes, every with its distinctive traits and benefits. Casting is thought for its capacity to supply advanced shapes and enormous parts, appropriate for a wide range of materials, together with metals and plastics. It’s notably well-suited for purposes that require excessive energy and sturdiness. Alternatively, molding is famend for its effectivity and precision, particularly appropriate for standardized parts that must be produced in massive portions and shortly.

Choosing the proper process is essential for product manufacturing. Producers ought to think about the next components:

- Complexity of the Product: Merchandise with advanced or distinctive shapes could also be higher suited to casting.

- Amount of Manufacturing: Merchandise that must be produced in massive portions could also be higher suited to molding.

- Kind of Materials: Totally different materials might have an effect on which process is chosen.

- Price and Time: Funds and manufacturing timelines are additionally necessary components in deciding the process.

Producers are suggested to think about not solely the present wants of the product but additionally future scalability and market adjustments when choosing a process. Understanding the traits and benefits of casting and molding might help producers make knowledgeable choices, thereby bettering product high quality, lowering prices, and finally assembly market calls for.

FAQs

Which is healthier, casting or molding?

The selection between casting and molding relies on numerous components, together with the complexity, dimension, materials, and finances for the required parts. Casting is appropriate for producing advanced shapes and enormous parts, whereas molding is good for quickly producing a lot of standardized small to medium-sized parts.

What materials are appropriate for casting?

Materials appropriate for casting embody numerous metals (corresponding to iron, steel, aluminum, and copper), plastics, and glass. These materials will be poured into molds in a molten state and retain their form upon cooling.

What kinds of merchandise will be produced by molding?

Molding is relevant for producing a variety of plastic and rubber merchandise, corresponding to containers, toys, elements for house home equipment, automotive inside parts, medical gadgets, and extra.

What are the price variations between casting and molding?

Casting has the next preliminary value as a result of want for sturdy molds and the price of melting materials. Nonetheless, for large-scale manufacturing, the unit value of casting might lower. Molding additionally might have a excessive preliminary funding, particularly for advanced molds, however its quick manufacturing pace and low vitality consumption make it appropriate for mass manufacturing.

How to decide on the suitable casting or molding process?

Selecting the suitable process includes contemplating:

- Product Design: The scale, form, and complexity of the product.

- Materials: The kind of materials required for the product.

- Amount: The variety of models and frequency of manufacturing.

- Price: Funds and cost-effectiveness evaluation.

- High quality Necessities: The standard and sturdiness necessities of the product.

- Manufacturing Time: The urgency of getting the product to market.

Useful resource

What is the Difference Between Molding and Casting?

What is the difference between molding and casting?