In the field of wood processing, CNC (computer numerical control) cutting and laser cutting are two mainstream precision processing technologies, but there are significant differences in their working principles, applicable scenarios and processing effects. CNC uses physical tools to cut wood and is suitable for three-dimensional engraving and thick material processing, while laser uses high-energy beams to vaporize materials and is good at ultra-fine cutting and complex pattern engraving. This article will deeply compare the differences between the two to help you choose the best processing method according to your project needs.

What Fundamental Principles Separate CNC and Laser Wood Cutting?

1. Essential differences in core processing mechanisms

CNC wood cutting principle:

- Mechanical energy conversion: convert electrical energy into mechanical kinetic energy through the spindle motor

- Contact cutting: carbide tools (common Φ3-12mm) directly contact the material surface

- Chip formation: the tool edge shears the wood fibers at a speed of 18,000-24,000 RPM

- Typical cutting force: about 5-20N/mm² (depending on the density of the wood)

Laser wood cutting principle:

- Light energy conversion: CO₂ laser converts electrical energy into 10.6μm wavelength infrared light

- Non-contact processing: The focused spot (diameter 0.1-0.3mm) gasifies the material through pyrolysis

- Gasification threshold: wood about 80J/cm² (pine) -150J/cm² (hardwood)

- Heat-affected zone: instantaneous temperature can reach 800-1200℃

2. Comparison of energy transfer paths

| Energy dimension | CNC cutting mechanism | Laser cutting mechanism |

|---|---|---|

| Energy form | Mechanical kinetic energy | Photothermal energy |

| Transmission medium | Tool entity | Laser beam |

| Action time | Continuous contact (milliseconds) | Pulse action (microseconds) |

| Energy density | Medium (50-200W/mm²) | High (500-5000W/mm²) |

| Energy loss | Frictional heat generation (about 15-30%) | Beam scattering (about 20-40%) |

3. Differences in material response characteristics

(1)Processing performance of hardwood (taking oak as an example)

CNC cutting:

- Forming continuous ribbon chips (thickness 0.1-0.3mm)

- Cutting temperature is about 120-200℃ (tool-material interface)

- Surface roughness Ra 3.2-6.3μm

Laser cutting:

- Producing pyrolysis gas (CO₂+H₂O+volatile organic matter)

- Carbonized layer thickness 0.3-1.2mm (positively correlated with power)

- Cutting speed is inversely proportional to density (the speed difference between pine and oak is about 35%)

(2) Key differences in engineered wood

CNC machining of plywood:

- Preferred compression spiral milling cutter (15° difference in helix angle between upper and lower blades)

- Recommended cutting amount per layer ≤2mm

- Feed speed 8-12m/min (anti-delamination)

Laser processing of plywood:

- Power density needs to be controlled <300W/cm²

- Optimal auxiliary gas pressure 0.3-0.5Bar (nitrogen is better)

- Edge carbonization degree is 20-40% higher than solid wood

4. Technology selection decision matrix

Select processing method according to material characteristics:

| Material parameters | CNC priority | Laser priority |

|---|---|---|

| Thickness | >8mm | ≤6mm |

| Hardness | Janka value >1000N | Janka value <800N |

| Resin content | >8% | <5% |

| Water content | 8-12% | ≤8% |

| Minimum feature size | ≥1mm | ≥0.3mm |

How Do Cutting Tolerances Compare in Fine Woodworking?

1. Detailed explanation of the precision advantages of CNC wood processing

(1)Positioning accuracy performance

- Three-dimensional spatial accuracy: in line with ISO 230-2 standard, up to ±0.05mm

- Repeat positioning accuracy: high-end models reach ±0.02mm (actual measurement by Heidenhain system)

- Straightness error: ≤0.03mm per 300mm (guaranteed by precision guide rails)

(2)Feature processing limit

- Processing feature Achievable accuracy Technical implementation conditions

- Minimum fillet 0.2mm Φ0.4mm carbide ball head tool

- Thin-wall structure 0.5mm thickness Use down milling + vacuum adsorption process

- Mortise and tenon fit clearance ≤0.1mm Tool radial runout ≤0.01mm

- Surface roughness Ra 1.6-3.2μm 60000RPM electric spindle + finishing tool path

Industry case: In the processing of mortise and tenon joints of classical furniture, CNC can achieve a fit clearance of 0.08mm, which is 5-8 times higher than the accuracy of traditional woodworking.

2. Precision characteristics and limitations of laser cutting

(1)Inherent precision advantage

- Two-dimensional contour accuracy: ±0.05mm (CCD positioning system)

- Minimum slit width: 0.15mm (130W CO₂ laser)

- Pattern reproducibility: Repeat error ≤±0.03mm

(2)Precision loss caused by thermal effects

Main defect types:

Incision slope phenomenon:

Typical value 0.1°-0.5°

- Relationship with focal length: The longer the focal length, the smaller the slope

- Compensation solution: Software preset 0.15° reverse taper

Edge carbonization effect:

- Carbonization layer thickness: 0.3-0.8mm (actual measurement of pine wood)

- Secondary grinding loss: average 0.5mm material loss

- Solution: Nitrogen protection cutting can reduce carbonization by 40%

- Thermal deformation error:ΔL=α×L×ΔT

Pine wood (α=4.5×10⁻⁶/℃) deforms 0.135mm at ΔT=300℃ for 100mm length

3. Material-related accuracy differences

| Wood type | Laser cutting accuracy retention rate | CNC cutting accuracy retention rate |

|---|---|---|

| Basswood | 98% | 99.5% |

| Oak | 95% | 99% |

| MDF | 92% | 97% |

| Plywood | 85%(easy to delaminate) | 96% |

4. Typical application tolerance standards for precision woodworking

(1) High-end watch gears:

Requirement: ±0.01mm

Must be processed by CNC (laser cannot guarantee tooth shape accuracy)

(2) Miniature architectural models:

Window frame tolerance: ±0.05mm

Preferred laser cutting (4 times more efficient than CNC)

(3) Musical instrument resonance box:

Soundboard thickness tolerance: ±0.03mm

Requires CNC sanding auxiliary processing

5. Professional solutions to improve precision

CNC precision optimization combination

Tool system:

- Select tool holders with runout below 3μm

- Perform dynamic balancing regularly (G2.5 standard)

Process parameters:

- Fine machining allowance 0.1mm

- Step distance ≤30% tool diameter

Environmental control:

- Temperature fluctuation within ±1℃

- Humidity 40-60%RH

- Laser precision compensation technology

Dynamic focusing system:

- Compensate for focal length changes (±0.02mm)

Real-time power adjustment:

- Automatically adjust according to cutting speed (50-120% range)

Edge processing solution:

- Low-temperature plasma post-processing (reduce carbonized layer)

6. Economical precision selection guide

Cost-precision balance point analysis:

| Precision requirements (mm) | Most cost-effective solution | Single piece processing cost (USD) |

|---|---|---|

| >0.1 | Ordinary laser cutting | 0.8-1.2 |

| 0.05-0.1 | High-precision CNC | 2.5-4 |

| <0.05 | Composite processing (laser + CNC) | 6-8 |

Which Wood Types Demand Strict Technology Selection?

In fine woodworking and industrial processing, the physical properties of different woods (such as resin content, density, type of glue) directly affect the safety, precision and quality of finished products of CNC and laser cutting. The following are the types of wood that require special attention and the corresponding technical selection points:

1. Wood with high resin content (pine, spruce, fir, etc.)

Processing characteristics and risks

Resin characteristics: easy to liquefy and volatilize at high temperatures, producing flammable gases (such as α-pinene and terpene compounds)

Laser cutting risks:

- Resin combustion leads to severe carbonization of cutting edges (carbonization layer can reach 1-2mm)

- Volatile substances may cause flash fires when exposed to high laser temperatures (Class IV fire protection system required)

- Smoke adheres to lenses, reducing beam quality (optical lenses need to be cleaned every hour)

CNC machining risks:

- Resin adheres to tools, resulting in a sudden increase in cutting force (tool life reduced by more than 50%)

- Chip accumulation causes local high temperatures (>150℃ may ignite dust)

Recommended processing plan

| Technology | Optimization measures | Applicable scenarios |

|---|---|---|

| Laser cutting | 1. Use nitrogen to assist cutting (suppress combustion) 2. Power density <200W/cm² (reduce carbonization) 3. Equipped with spark detection + automatic fire extinguishing system | Thin plate (<6mm) decorative parts |

| CNC cutting | 1. Use PTFE coated tools (anti-adhesion) 2. Compressed air cooling (pressure ≥0.6MPa) 3. Increase feed speed (>10m/min to reduce heat accumulation) | Structural parts, thick plate processing |

Case: When laser cutting pine wood, nitrogen protection can reduce the carbonization layer from 1.2mm to 0.3mm, but the cost increases by 30%.

2. Artificial boards (MDF, plywood, OSB)

Processing characteristics and risks

Adhesive issues: Formaldehyde-based resins release VOCs (volatile organic compounds) at high temperatures, and the concentration can reach 50ppm during laser cutting (10 times the OSHA limit)

Laser cutting risks:

- Delamination (vaporization of adhesive leads to interlayer peeling)

- Uneven edge carbonization (difference in density leads to rough cutting surface)

- Formaldehyde release requires water-cooled cutting table + activated carbon filtration (compliance requirements)

- Fine dust (particle size <10μm) is explosive (ATEX standard limit 30g/m³)

- Fast tool wear (high silica content in MDF)

Recommended processing solutions

| Technology | Optimization measures | Applicable scenarios |

|---|---|---|

| Laser cutting | 1. Low-power multi-pass cutting (<80W) 2. Water-cooled workbench cooling (inhibiting formaldehyde release) 3. HEPA+activated carbon filtration system | Furniture hollow decoration |

| CNC cutting | 1. Use diamond-coated tools (wear resistance increased by 3 times) 2. Wet dust removal system (dust concentration <20g/m³) 3. Spiral cutting (angle <5° to prevent delamination) | Load-bearing structure processing |

Data comparison: When laser cutting MDF, the water cooling system can reduce formaldehyde release by 70%, but the processing speed is reduced by 40%.

3. High-density hardwood (oak, walnut, rosewood)

Processing characteristics and risks

Material hardness: Janka hardness > 1000N (laser power needs to be increased to more than 150W)

- Low energy absorption rate (requires repeated cutting)

- Uneven carbonization depth (significant difference between heartwood and sapwood)

CNC machining risks:

- High cutting force (spindle load increased by 50%)

- Tool chipping risk (recommended rake angle <15°)

Recommended processing plan

| Technology | Optimization measures | Applicable scenarios |

|---|---|---|

| Laser cutting | 1. High peak power pulse mode (duty cycle <30%) 2. Pre-coated light-absorbing coating (to improve energy absorption) | Fine mosaic pattern |

| CNC cutting | 1. Low speed and high feed (to avoid work hardening) 2. Step cutting (each layer ≤2mm) 3. Oily coolant (to reduce tool wear) | High-end furniture mortise and tenon |

4. Specially treated wood (flame retardant wood, antiseptic wood)

Processing characteristics and risks

Chemical additives: borates, ammonium phosphates, etc. affect cutting performance

Laser cutting risks:

- Vaporization of additives produces toxic smoke (chemical filters are required)

- Cutting speed is reduced by 60% (thermal conductivity changes)

CNC machining risks:

- Tool corrosion (alkaline preservatives accelerate wear)

Solutions

- Laser: Increase exhaust speed (≥50m/s)

- CNC: Use ceramic coated tools instead

Key conclusions:

- Resin wood prefers CNC (high safety), lasers must be strictly flame-proof

- Artificial boards must be equipped with environmentally friendly treatment systems (compliance first)

- Hardwood processing CNC is more economical, lasers are only used for ultra-fine parts

- By matching material properties and technical parameters, processing risks and costs can be reduced by more than 30%.

How Does Production Speed Vary by Thickness?

In sheet metal fabrication, thickness affects the production speed, and different processing methods have their own advantages in each thickness range.

1.Sheet cutting (<6mm): Laser speed leading

Laser cutting speed advantage

- 3mm oak sheet: 150W CO₂ laser cutting speed 3 – 5 m/min, CNC cutting (Φ6mm end mill) only 0.8 – 1.2 m/min, laser 3 – 5 times faster than CNC.

- 5mm MDF / Plywood: Laser cutting speed 4 – 6 m/min under nitrogen protection, CNC (helical mill) 1 – 1.5 m/min.

Additional cost of lasers

Laser cutting is fast, but it takes 10 to 20% more time to scorch the edges, nitrogen cutting reduces carbonization but increases costs, and small batches require positioning and parameter adjustment. For large-size sheet processing (such as furniture hollow parts), the laser selection should include the post-processing cost.

2.Plate (6 – 25mm): CNC is gradually dominating

Laser cutting efficiency is reduced

- 10mm pine: 2 – 3 passes for the laser, 0.8 – 1.2 m/min; CNC single knife straight cutting up to 1.5 – 2 m/min.

- 15mm Oak: 300W power ≥ laser and 0.5 m/min speed; CNC layered cutting can sustain 1 m/min.

Advantages of CNC

- One-time molding: CNC machining of medium and heavy plates can be done in a single pass, without the need for multi-layer scanning like lasers.

- No thermal effects: the processing process does not affect the strength of the wood.

- Low cost: CNC tooling costs less than laser power consumption, and the total CNC cost of 12mm sheet is 20 – 30% lower than that of lasers.

3.Thick plate (>25mm): CNC has outstanding advantages

Limitations of lasers

- Processing thick plates, 500W power is required for lasers, 5 – 8 scans are required to cut 30mm plates, poor edge quality, and slope > 1°.

Efficient CNC machining

- Tool stability: The tool overhang ratio is 1:5 stable, such as Φ10mm tool can process 50mm thick plates.

- Adaptive technology: automatic deceleration of hardwood to prevent tool breakage.

- No material restrictions: Logs of more than 100 mm can be processed.

| Thickness | Laser Applicability | CNC Applicability | Recommended Technology |

|---|---|---|---|

| <6mm | ★★★★★ | ★★☆☆☆ | Laser |

| 6-25mm | ★★☆☆☆ | ★★★★☆ | CNC |

| >25mm | ★☆☆☆☆ | ★★★★★ | CNC |

4. Production speed formula reference

Laser cutting time estimation

Tlaser=L/Vcut+(Npass×Treposition)+Tclean

- L = cutting path length (m)

- Vcut= cutting speed (m/min)

- Npass= number of scans (thick plates require multiple scans)

- Tclean= post-processing time

CNC cutting time estimation

TCNC=L/Vfeed×Nlayer

- Nlayer=Number of layers (cut depth per layer 3-5mm)

5. Technology selection suggestions

- Mass production of thin plates → Laser cutting (efficiency first)

- Medium and thick plate structural parts → CNC cutting (quality and speed)

- Ultra-thick/special-shaped processing → CNC is the only choice

Note: Mixing two technologies (such as laser cutting + CNC finishing) can optimize overall production efficiency!

What Hidden Costs Impact Profit Margins?

1. Hidden costs of laser cutting

(1) Optical system loss

Shortened lens life:

- Resin contamination during wood cutting → Replacement required every 300-500 hours (1/3 life of metal cutting)

- Cost: $150-400/piece (ZnSe focusing lens)

Laser tube attenuation:

- CO₂ laser tube power decreases by 10-15% per year, affecting cutting speed

(2)Auxiliary gas cost

| Gas type | Cost increase | Applicable scenarios |

|---|---|---|

| Compressed air | $0.3/h | Ordinary cork |

| Nitrogen | $1.2/h | Anti-carbonization cutting |

| Oxygen | $0.8/h | High-power deep carving |

Example: 8 hours of continuous nitrogen protection cutting, $9.6 cost increase per day

(3)Post-processing requirements

- Scorch polishing: additional 5-10 minutes/㎡ labor

- Exhaust gas treatment: activated carbon filter replaced every 500 hours ($200/set)

2. Hidden costs of CNC machining

(1)Tool consumption

Tool life comparison:

| Material | Tool life (hours) | Unit price |

|---|---|---|

| Pine | 30-50 | $20-40 |

| Oak/walnut | 8-15(Daijie coating) | $50-120 |

| MDF | 15-25(diamond tool) | $80-200 |

- Loss of tool change downtime:

- Each tool change takes 5-10 minutes

- Downtime cost of a medium-sized workshop $45/h

(2)Dust management

- Dust collection system energy consumption: 2-3kW fan running continuously

- Explosion-proof certified equipment: ATEX dust collectors are 2-3 times more expensive than ordinary models

(3)Fixture and positioning wear

- Vacuum adsorption pads: Replace every 6-12 months ($200-500/㎡)

- Fixture wear: High-frequency processing leads to accumulation of positioning errors

3. Common hidden costs

(1)Equipment maintenance

Project Laser cutting CNC cutting

Annual maintenance cost $2000-5000 $1500-4000

Replacement cycle of key components Laser tube 1-2 years Guide rail 3-5 years

(2) Energy consumption

Laser equipment:

- 150W CO₂ laser ≈ 10kW (including cooling system)

- Monthly electricity bill for continuous work $600-800

- 5.5kW spindle ≈ 8kW (including dust removal)

- Equivalent working hours electricity bill $400-600

(3)Waste treatment

- Laser carbonization waste: needs to be treated as hazardous waste (extra charge in some areas)

- CNC dust recycling: MDF dust cannot be directly landfilled (professional recycling is required)

4. Cost optimization strategy

Money-saving tips for laser cutting

- Lens cleaning procedure:Wipe with anhydrous ethanol every 4 hours → Extend life by 30%

- Gas replacement solution:Replace nitrogen with air compressor + dryer (when carbonization is acceptable)

CNC machining cost reduction method

- Tool monitoring system:Install acoustic emission sensors to reduce excessive tool changes

- Cutting parameter optimization:Use high feed milling (HFM) for hardwood to improve efficiency by 20%

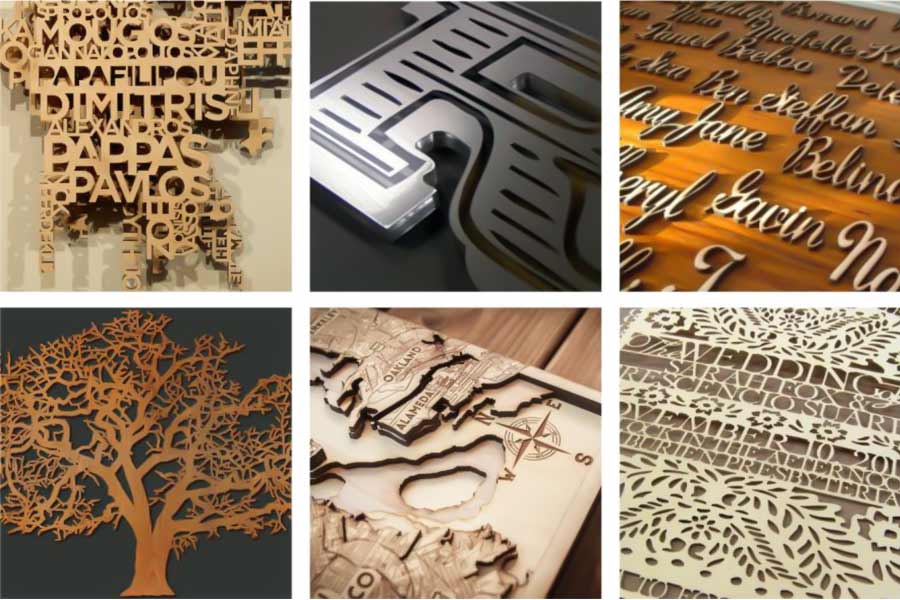

How Do Surface Finishes Affect Product Value?

1. Surface characteristics and value impact of laser cutting

(1)Duality of carbonized texture

Artistic application:

- The brown carbonized layer creates a unique visual effect (especially walnut and oak)

- High-end case: Imitation of Japanese “burned cedar board” process (saving 30% of traditional carbonization cost)

- UV coating curing is required (increase cost of $2-3 per square meter)

Industrial product taboos:

| Application scenario | Surface requirements | Post-processing solution |

|---|---|---|

| Food contact products | Ra<3.2μm | 400-600 grit sandpaper fine grinding |

| Children’s toys | Zero carbonization residue | CNC milling after laser (0.2mm removal) |

| Medical equipment components | Microbiological testing meets standards | Plasma cleaning + food-grade epoxy coating |

2. Surface precision control technology of CNC machining

(1) Directional processing of wood grain

- Cutting along the grain: Ra 1.6-2.5μm (mirror effect)

- Cutting against the grain: Ra 4.5-6.3μm (secondary processing required)

- End cutting: Ra 8-12μm (must be trimmed with a ball-end cutter)

Application of high-end furniture:

- 45° oblique grain cutting balances efficiency and quality (Ra 2.8-3.5μm)

- For every 10° adjustment of the tool angle, the processing time increases by 8%

(2) Finishing cost structure

| Process | Time Ratio | Value Increase |

|---|---|---|

| Roughing | 40% | +5% |

| Semi-finishing | 25% | +15% |

| Finishing | 35% | +30-50% |

Typical case:

- The price of a mahogany tea tray after finishing (4 hours) is 3 times higher than that of a roughing (1 hour)

- Fine milling of the inner wall of a musical instrument resonance box (Ra<1.8μm) improves the sound quality score by 20%

3. Surface treatment technology selection guide

(1)Select by product positioning

Luxury goods/artworks:

- Preferred laser natural carbonization + lacquer protection (traditional craftsmanship premium 40%+)

- Or CNC 5-axis precision carving (Ra<1μm)

Industrial-grade products:

- Laser cutting + automated sanding (optimal cost)

- CNC carbide knife one-time molding (Ra 3.2μm standard)

(2)Select by material characteristics

| Wood type | Recommended surface solution | Value increase |

|---|---|---|

| Pine/fir | Laser carbonization + distressing treatment | +25% |

| Walnut/ebony | CNC milling along the grain + wood wax oil | +60% |

| Bamboo | laminate Laser cutting + CNC chamfering | +35% |

4. Innovative surface treatment technology

(1)Laser-CNC composite process

Three-step method:

- Laser rough cutting (retaining 0.5mm margin)

- CNC fine shaping (Ra 1.6μm)

- Laser surface microtexture (200μm deep decorative pattern)

Benefits:

- Total working hours reduced by 25%

- Product unit price increased by 40%

(2)Nano coating technology

CNC machining post-processing:

- Silicon dioxide impregnation (enhanced surface hardness 3 times)

- Hydrophobic coating (contact angle > 110°)

- Cost: Increased $8-12/㎡, but durability increased by 200%

Key conclusions:

- Laser charring textures are suitable for artistic and retro style products

- CNC finishing is a must for high-end functional products

- Hybrid processes are becoming the gold standard for products with a premium of 50%+

Conclusion

The core difference between CNC and laser cutting wood lies in the processing principle and application characteristics: CNC uses physical tool contact cutting, which is suitable for three-dimensional processing and thick materials (up to 100mm or more), and can retain the natural texture of wood but there is a cost of tool wear; laser uses high-energy beams to vaporize materials without contact, and is good at ultra-fine cutting of thin plates (<12mm) and complex pattern processing. A carbonized layer will form on the edge but there is no need to change the tool. When choosing, CNC is more suitable for structural parts and three-dimensional engraving, while laser wins in two-dimensional fine processing efficiency. The two have different focuses on accuracy, cost and safety requirements. The actual selection needs to comprehensively consider material properties, production scale and finished product requirements.

📞 Phone: +86 185 6675 9667

📧 Email: info@longshengmfg.com

🌐 Website: https://www.longshengmfg.com/

🔔Subscription Guide-Scroll to the bottom of the website, enter your email address, and click √Subscribe

Disclaimer

The content appearing on this webpage is for informational purposes only. LS makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LS’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LS

This article was written by various LS contributors. LS is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

FAQs

1. Which is better, laser cutting machine or CNC?

Laser cutting machines and CNC have their own advantages, and the choice depends on the specific needs: laser cutting machines are more efficient in fine machining of thin sheets (<6mm) and are suitable for complex patterns and small batch production, while CNC is more advantageous in heavy material processing, three-dimensional engraving and structural parts manufacturing, especially for scenarios that require high-precision mortise and tenon joints or avoid thermal influences, and the two complement rather than replace.

2. What are the disadvantages of laser cutting wood?

The main disadvantages of laser-cut wood include carbonization at the edges (which requires additional treatment), limited thickness (typically ≤ 12mm), volatile and flammable gases from resinous woods (such as pine), and the possible release of formaldehyde when cutting plywood, which can affect processing efficiency, safety, and post-processing costs.

3. Is laser cutting a type of CNC?

Laser cutting belongs to one of the applications of CNC (Computer Numerical Control) technology, but not all CNC is laser cutting; CNC is a generalized control system that can drive a variety of tools such as laser heads, milling cutters, etc., while laser cutting machines specifically refer to CNC equipment that uses high-energy beams for processing, and the relationship between the two is contained and included.

4. Can laser CNC cut wood?

Laser CNC can cut wood, but the parameters need to be adjusted according to the material characteristics: low resin wood (such as basswood, MDF) works best, while pine or plywood needs to be combined with nitrogen protection and safety smoke extraction system, and the power is recommended to be more than 80W (cut 3mm) or more than 150W (cut 6-8mm), and traditional CNC milling is still recommended for thick wood.