What is the difference between CNC milling and CNC turning?CNC milling and CNC turning are two of the most common manufacturing processes used in modern industries. While both techniques are used to create complex and intricate parts, there are several key differences between the two approaches. In this article, we will explore the differences between CNC milling and CNC turning, their applications, and their advantages and disadvantages.

CNC Milling

CNC milling is a process that uses a rotating cutting tool to remove material from a workpiece. The workpiece is held in place on a milling machine, and the cutting tool moves along multiple axes to create the desired shape. This process can be used to create complex shapes, holes, and slots in a variety of materials, including metals, plastics, and composites.

One of the main advantages of CNC milling is that it can be used to create parts with high precision and accuracy. This process is also highly versatile, allowing for the creation of parts with a wide range of shapes and sizes. Additionally, CNC milling can be used to create parts in large quantities, making it an ideal choice for mass production.

CNC Turning

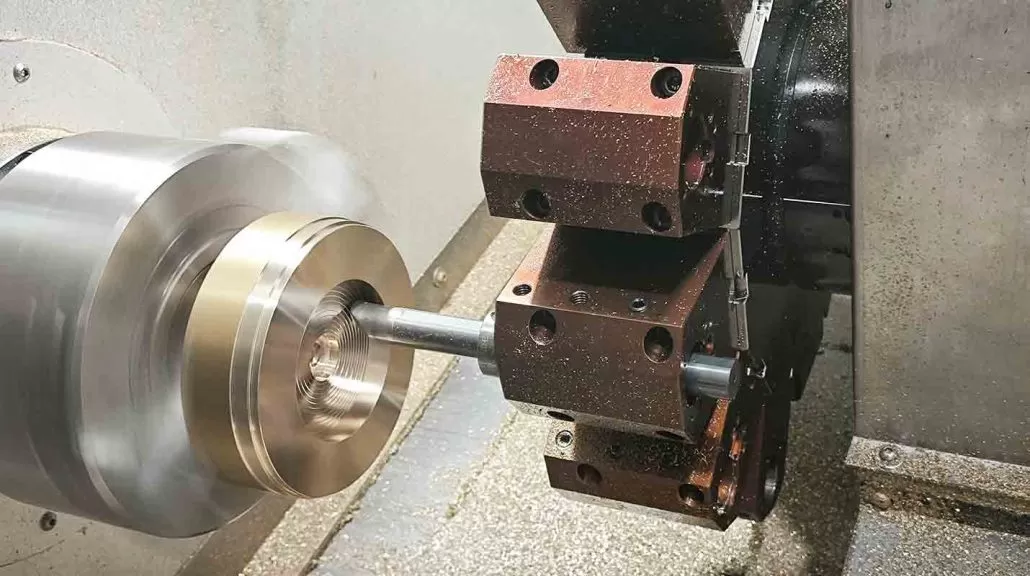

CNC turning is a process that uses a rotating workpiece and a stationary cutting tool to create cylindrical shapes. The workpiece is held in place on a lathe, and the cutting tool moves along a single axis to remove material from the workpiece. This process can be used to create parts with a high degree of symmetry, such as screws, bolts, and other cylindrical shapes.

One of the main advantages of CNC turning is that it can be used to create parts with a high level of precision and accuracy. This process is also highly efficient, allowing for the creation of complex parts in a relatively short amount of time. Additionally, CNC turning can be used to create parts in large quantities, making it an ideal choice for mass production.

Differences between CNC Milling and CNC Turning

While both CNC milling and CNC turning are used to create complex and intricate parts, there are several key differences between the two approaches. These include:

- The direction of the cutting tool: In CNC milling, the cutting tool moves along multiple axes, while in CNC turning, the cutting tool moves along a single axis.

- The shape of the workpiece: CNC milling is used to create parts with complex shapes, while CNC turning is used to create cylindrical shapes.

- The precision of the process: Both CNC milling and CNC turning can be used to create parts with a high level of precision and accuracy, but CNC turning is generally more precise due to the use of a single cutting tool.

- The materials that can be used: CNC milling can be used to create parts from a wide range of materials, including metals, plastics, and composites, while CNC turning is generally used for creating parts from metals.

Applications of CNC Milling and CNC Turning

CNC milling and CNC turning are used in a wide range of industries, including aerospace, automotive, medical, and electronics. Some of the common applications of these processes include:

CNC Milling:

- Creating complex parts with high precision and accuracy

- Creating parts with intricate shapes and contours

- Creating molds and dies for injection molding and casting

- Creating parts for the aerospace and defense industries

CNC Turning:

- Creating cylindrical parts with high precision and accuracy

- Creating screws, bolts, and other fasteners

- Creating parts for the automotive and medical industries

- Creating parts for the electronics industry

Advantages and Disadvantages of CNC Milling and CNC Turning

Both CNC milling and CNC turning have their advantages and disadvantages.

Some of the advantages of CNC milling include:

- Versatility: CNC milling can be used to create parts with a wide range of shapes and sizes.

- Precision: CNC milling can create parts with high precision and accuracy.

- Efficiency: CNC milling can be used to create complex parts in a relatively short amount of time.

Some of the disadvantages of CNC milling include:

- Complexity: CNC milling machines can be complex and expensive.

- Maintenance: CNC milling machines require regular maintenance to ensure they remain in good working condition.

- Setup time: Setting up a CNC milling machine can be time-consuming and requires skilled operators.

Some of the advantages of CNC turning include:

- Efficiency: CNC turning can create parts in a relatively short amount of time.

- Precision: CNC turning can create parts with a high degree of precision and accuracy.

- Versatility: CNC turning can be used to create a wide range of cylindrical parts.

Some of the disadvantages of CNC turning include:

- Limited shape: CNC turning is limited to creating cylindrical shapes.

- Limited materials: CNC turning is generally used for creating parts from metals.

- Maintenance: CNC turning machines require regular maintenance to ensure they remain in good working condition.

Conclusion

In conclusion, CNC milling and CNC turning are two of the most common manufacturing processes used in modern industries. While both techniques are used to create complex and intricate parts, they have several key differences in terms of their approach, applications, and advantages and disadvantages. By understanding the differences between CNC milling and CNC turning, manufacturers can choose the best approach for their specific needs and requirements.