Injection molding is a widely used manufacturing process that involves the production of highly precise and complex parts and components. One of the key factors that determine the quality and functionality of injection-molded products is the material used in the process. With a plethora of options available, choosing the right material for your application can be a daunting task. In this article, we will provide you with a comprehensive guide on what material to use for different injection molding applications.

Types of Injection Molding Materials,Injection molding materials can be broadly classified into four categories: thermoplastics, thermosetting plastics, elastomers, and metals. Each category has its unique properties and characteristics that make it suitable for specific applications.

Thermoplastics

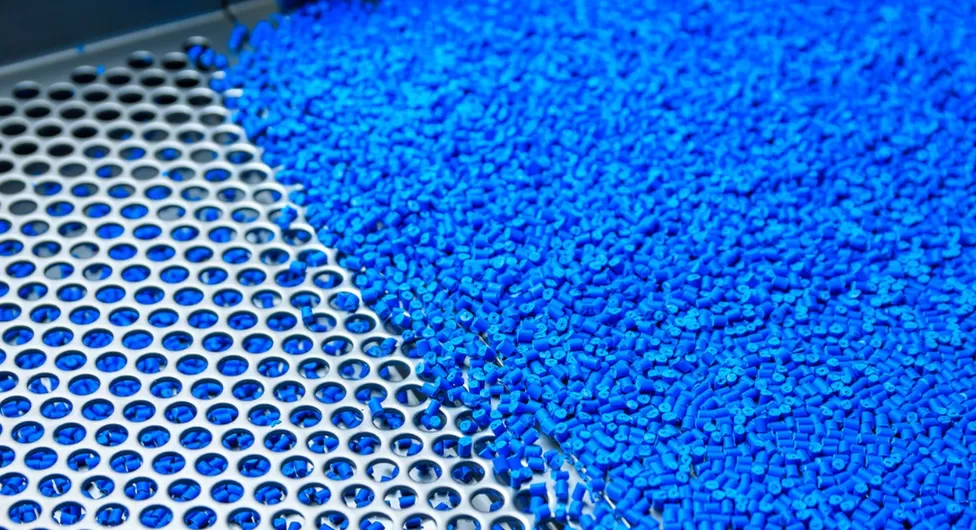

Thermoplastics are the most commonly used injection molding materials due to their versatility and ease of processing. They can be repeatedly melted and solidified using heat and pressure, making them ideal for high-volume production. Some popular types of thermoplastics used in injection molding include:

a) Polyethylene (PE): It is a low-cost, lightweight, and flexible polymer that is widely used in packaging, consumer goods, and automotive applications.

b) Polypropylene (PP): It is a durable and heat-resistant plastic that is commonly used in the production of caps, closures, and containers.

c) Acrylonitrile Butadiene Styrene (ABS): It is a tough and impact-resistant plastic that is widely used in the automotive industry for interior and exterior components.

d) Polycarbonate (PC): It is a transparent, lightweight, and impact-resistant plastic that is commonly used in electronic and automotive applications.

Thermosetting Plastics

Thermosetting plastics are materials that undergo a chemical reaction when heated, forming a rigid and irreversible structure. This property makes them ideal for applications that require high strength and dimensional stability. Some popular types of thermosetting plastics used in injection molding include:

a) Phenolic Resin: It is a thermosetting plastic that is resistant to heat and chemicals, making it ideal for electrical and automotive applications.

b) Epoxy Resin: It is a thermosetting plastic that has excellent mechanical and electrical properties, making it ideal for aerospace and electronic applications.

c) Polyester Resin: It is a versatile thermosetting plastic that is commonly used in construction, transportation, and marine applications.

Elastomers

Elastomers are materials that can stretch and return to their original shape when subjected to force or pressure. They are commonly used in applications that require flexibility, durability, and cushioning. Some popular types of elastomers used in injection molding include:

a) Natural Rubber: It is a highly elastic and durable material that is commonly used in automotive, construction, and consumer goods applications.

b) Silicone: It is a soft and flexible material that is resistant to heat and chemicals, making it ideal for medical and electronic applications.

c) Thermoplastic Elastomers (TPE): They are materials that combine the properties of thermoplastics and elastomers, making them ideal for applications that require flexibility and durability.

Metals

Metal injection molding (MIM) is a variation of injection molding that involves the production of metal parts using powder injection molding technology. This process is ideal for producing high-strength and high-precision metal parts for various applications.

Factors to Consider When Choosing a Material

Selecting the right material for your injection molding application involves the consideration of various factors, including:

Mechanical Properties: The material should possess the required strength, toughness, and dimensional stability for the application.

Chemical Resistance: The material should be resistant to the corrosive effects of the environment and any chemicals that it may encounter.

Temperature Resistance: The material should be able to withstand the operating temperatures of the application without losing its properties.

Cost: The material should be cost-effective for the application and the desired production volume.

Choosing the right material for your injection molding application is crucial for achieving high-quality and functional products. With the information provided in this article, you can make an informed decision on what material to use for your specific application. Remember to consider the mechanical properties, chemical resistance, temperature resistance, and cost when selecting a material.