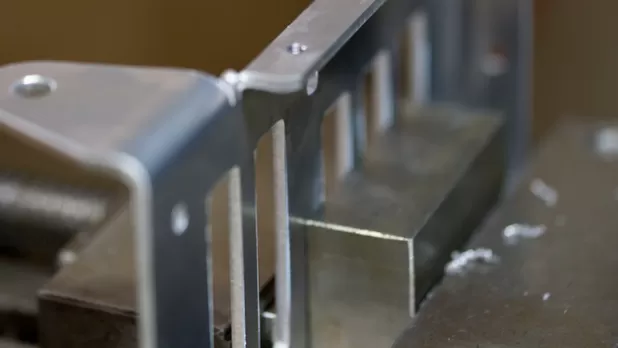

Sheet metal fabrication is a versatile and widely used process in the manufacturing industry. It involves the cutting, shaping, and bending of metal sheets to create a range of products used in various industries such as construction, automotive, aerospace, and manufacturing. The products created through sheet metal fabrication are diverse and include everything from simple brackets to complex machine parts.

The process of sheet metal fabrication requires the use of a variety of materials, each with its own unique properties and advantages. Some of the most commonly used materials in sheet metal fabrication include steel, aluminum, copper, and brass. In this article, we will explore each of these materials in detail and their specific uses in sheet metal fabrication.

Steel

Steel is the most common material used in sheet metal fabrication. It is known for its strength, durability, and versatility. Steel sheets can be easily cut and shaped into complex forms, making it ideal for creating products with intricate designs. Steel is also resistant to corrosion, making it suitable for outdoor applications. The most common types of steel used in sheet metal fabrication are carbon steel, stainless steel, and galvanized steel.

Carbon steel is the most commonly used type of steel in sheet metal fabrication. It is strong, durable, and relatively inexpensive. It is often used to create products that require high strength, such as machinery parts and structural components.

Stainless steel is another popular choice for sheet metal fabrication. It is highly resistant to corrosion and is commonly used in food processing and medical industries because of its hygienic properties.

Galvanized steel is steel that has been coated with a layer of zinc to increase its resistance to corrosion. It is commonly used in outdoor applications such as roofing, fencing, and gutters.

Aluminum

Aluminum is another popular material used in sheet metal fabrication. It is known for its lightweight, corrosion resistance, and high strength-to-weight ratio. Aluminum sheets are easy to form and can be cut, bent, and welded to create various products. It is commonly used in the aerospace and automotive industries due to its lightweight properties.

Aluminum is a popular choice for creating products that require a high strength-to-weight ratio, such as aircraft components and automobile parts. It is also commonly used in the construction industry for roofing, siding, and gutters.

Copper

Copper is a soft and ductile material that is commonly used in sheet metal fabrication. It is known for its excellent conductivity, making it ideal for creating electrical components. Copper sheets are also resistant to corrosion, making them suitable for outdoor applications. Copper is commonly used in the construction industry for roofing, gutters, and flashing.

Copper is a popular choice for creating electrical components because of its high conductivity. It is commonly used in electrical wiring, motors, and generators. Copper is also used in the construction industry for roofing, gutters, and flashing because of its resistance to corrosion.

Brass

Brass is an alloy of copper and zinc that is commonly used in sheet metal fabrication. It is known for its excellent corrosion resistance and is often used in marine applications. Brass sheets are also easy to form and can be cut, bent, and welded to create various products. It is commonly used in the manufacturing of musical instruments and decorative objects.

Brass is a popular choice for creating products that require a high level of corrosion resistance, such as marine hardware and plumbing fixtures. It is also commonly used in the manufacturing of musical instruments and decorative objects because of its attractive appearance.

Conclusion

Sheet metal fabrication is a versatile process that requires the use of various materials. Steel, aluminum, copper, and brass are the most commonly used materials in sheet metal fabrication. Each material has its own unique properties and advantages, making it suitable for different applications. When choosing a material for your sheet metal fabrication project, it is important to consider factors such as strength, durability, corrosion resistance, and cost. By understanding the properties of each material, you can choose the best material for your specific application and enhance the quality of your final product.