Injection molding has become a widely popular manufacturing process throughout various industries for the creation of many different parts. Injection molding is a highly versatile manufacturing method that allows for the creation of complex geometries and unique designs in a timely and cost-efficient manner. In this article, we will delve deeper into the world of injection molding and explore the products that use this manufacturing process.

What is Injection Molding?

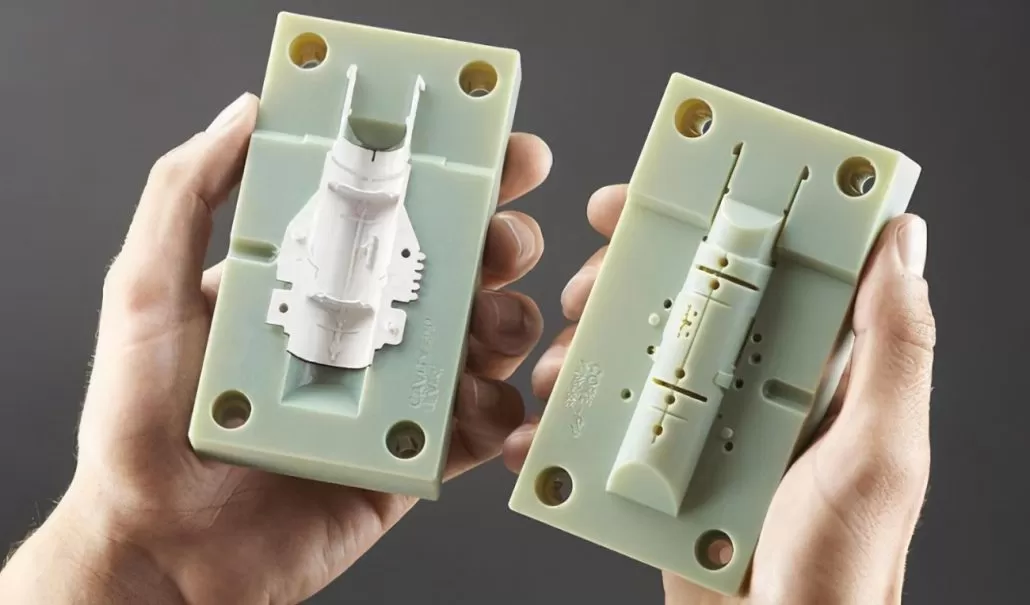

Injection molding is a manufacturing Injection molding process that involves the melting of resin pellets into a mold cavity. Once the material cools and hardens, it takes on the shape of the mold, creating a solid part. Injection molding is commonly used for the production of parts such as gears, housings, and containers, as well as more complex parts such as automotive body panels, medical devices, and consumer electronics.

Products that use Injection Molding

Injection molding is used in a wide range of industries, and products can vary significantly from industry to industry. Some of the most common products that use injection molding include:

Automotive Parts – Injection molding is frequently used in the production of automotive parts such as bumpers, instrument panels, and interior trim. Injection molding allows for the creation of complex geometries and intricate designs that are often required for these types of parts.

Medical Devices – Injection molding is used to produce medical devices such as syringes, inhalers, and surgical instruments. The high precision and accuracy of injection molding make it a popular choice for the production of medical devices, where consistency and safety are crucial.

Consumer Electronics – Injection molding is used to create products such as phone cases, laptop covers, and other electronic devices. Injection molding allows for the creation of complex shapes and designs, making it a popular choice for high-end electronic devices.

Packaging – Injection molding is used to produce items such as plastic bottles, jars, and containers for the food, beverage, and cosmetics industries. Injection molding allows for the creation of airtight, leak-proof containers that protect products during storage and transportation.

Household appliances – Injection molding is used to produce components of household appliances such as washing machines, vacuum cleaners, and refrigerators. Injection molding provides high durability for these products and high precision control for complex shapes and letters.

Benefits of Injection Molding

Injection molding offers several benefits that make it the preferred choice for many manufacturers. These benefits include:

High efficiency:Injection molding produces high-quality products in a quick and efficient manner, which helps to reduce manufacturing costs.

Versatility:Injection molding can accommodate different materials, colors, and textures to provide a wide range of design options for manufacturers.

High Precision:Injection molding provides high precision with tight tolerances that make it an ideal choice for complex geometries and intricate designs.

High durability:Injection molded products often have high durability and resistance to wear and tear.

High Production Speed:Injection molding is a fast production method with a molding cycle time of a few seconds. The speed is due to the fact that the molten plastic is injected into the molds at high velocity.

Low Labor Costs :Once the mold has been created, the production process is highly automated, leading to cost savings on labor.

Low Material Waste :The precise nature of injection molding reduces material waste during production, leading to cost savings.

Ability to Produce Complex Shapes:Injection molding allows for the production of complex shapes, something that cannot be achieved using other manufacturing techniques.

Injection molding is a popular choice for manufacturing various products across different industries because of its efficiency, versatility, precision, and durability. As you can see, the use of injection molding is vast and diverse. If you are in the market for a product that has been made using this manufacturing process, you can be confident that your product was created with quality and cost-efficiency in mind. Injection molding will continue to play an important role in modern manufacturing practices as the need for high-quality, cost-effective products continues to rise.