1–What is 3D Printing?

3D printing is a way to prototype parts rapidly in which a real object is created from a 3D design.

The digital 3D model can be saved in a variety of standard formats including STL and OBJ and then uploaded to a 3D printer for processing. The 3D printer then prints the design layer by layer and forms a real object.

3D printing is an additive technology used to manufacture parts. It is ‘additive’ in that it doesn’t require a block of material or a mold to manufacture physical objects, it simply stacks and fuses layers of material. It’s typically fast, with low fixed setup costs, and can create more complex geometries than ‘traditional’ technologies, with an ever-expanding list of materials. It is used extensively in the engineering industry, particularly for prototyping and creating lightweight geometries.

2-Why use 3D Printers for Rapid Prototyping?

In short: it’s fast and relatively cheap. From idea to 3D model to holding a prototype in your hands is a matter of days instead of weeks. Iterations are easier and cheaper to make and you don’t need expensive molds or tools.

Besides rapid prototyping, 3D printing is also used for rapid manufacturing. Rapid manufacturing is a new method of manufacturing where businesses use 3D printers for short-run / small-batch custom manufacturing.

3–What is the difference between SLA and SLS?

SLA or stereolithography is also known as resin 3d printing. This type of 3d printing is well known for its ability to produce highly accurate objects and parts with various materials. SLA 3d printed parts contain a smooth and accurate finish. Although the basic principle is more or less the same, SLA printers cure liquid resins to hard plastics.

SLS or selective laser sintering on the other hand is a completely different 3D printing technique. It belongs to the powder bed fusion family. The materials used in this technique come in the form of powder. The powder is spread across the print bed, then a laser sinters the powder particles in the form of the first layers of the object. The print bed then lowers, a recoating blade spreads a new layer of powder across the board, a laser draws the second layer, and so on. SLS printing is used for making complex shapes and producing prints with a top-notch finish.

But the end product differs between SLA and SLS parts. SLA parts have the highest accuracy, precise finish, and accurate details. Print quality is way better than SLS and FDM printers, hence it is used for making prototypes and various tools.

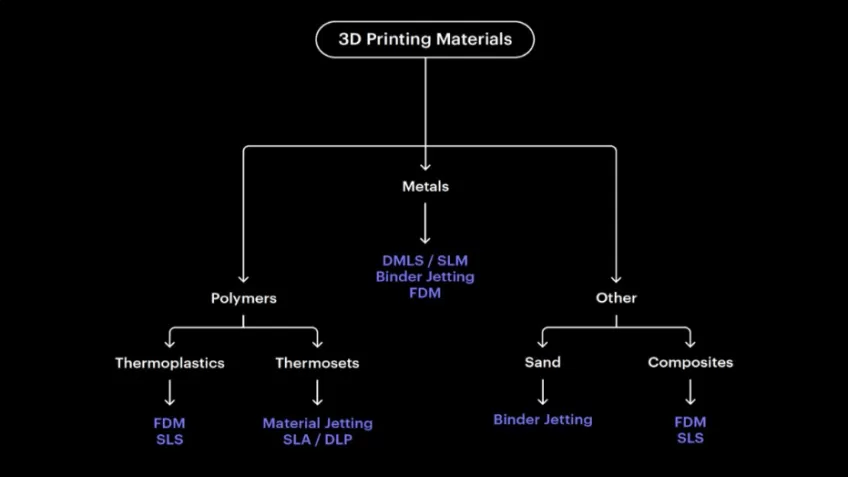

4-What is the material used when 3D printing?

The number of available 3D printing materials grows rapidly every year as market demand for specific materials and mechanical properties spurs advancements in material science. This makes it impossible to give a complete overview of all 3D printing materials, but each 3D printing process is only compatible with certain materials so there are some easy generalizations to make.

Thermoplastic and thermoset polymers are by far the most common 3D printing materials, but metals, composites, and ceramics can also be 3D printed.

5-How long does a 3D print take?

That depends on several factors:

The size of your model

The material you are using

The layer height (smaller layers mean more layers to print)

The complexity of your model

Whether the object needs support

The most common slicers give to you the estimated time to print the model, but since external factors affect the job the print could use more time or less.

6-Where can I print 3D parts?

Longsheng Technology provides 3D printing services to customers and helps them take the design from concept to reality. The factory is based in Dongguan City, China. Providing our customers with a comprehensive One-Stop Manufacturing Solution.

7-Applications of 3D printing

3D printing is exceptionally useful for prototyping. Speed is everything in prototyping, and the ability to move from CAD to print with close to zero set up costs means 3D printers can produce parts fast and have great unit economics for single-part and small runs.

For printing production parts, speed and price are also important, but the characteristics most commonly exploited are design freedom and ease of customization. In aerospace and automotive, topology-optimized structures with a high strength-to-weight ratio are used for high-performance parts, and components that previously required assembly can be consolidated into a single part. In healthcare, customization is critical – most hearing aids manufactured in the US are made almost exclusively using 3D printing. In manufacturing, low-run injection molds can be 3D printed from stiff, heat-resistant plastics instead of machined from metal, making them much cheaper and faster to produce.

8–What are the benefits of 3D printing?

3D printing is an exceptional tool for custom parts and rapid prototyping with a unique set of advantages but also lags behind traditional manufacturing in some ways. The key benefits and limitations can be summarized as follows:

Benefits

– Very low start-up costs

– Very quick turnaround

– Large range of available materials

– Design freedom at no extra cost

– Each and every part can easily be customized