3D printing has revolutionized manufacturing and prototyping by permitting the creation of advanced and customised objects layer by layer. A wide selection of supplies can be utilized in 3D printing, every providing distinctive properties and purposes. The commonest materials is plastic, which is favored for its versatility, cost-effectiveness, and the vary of colours and transparencies accessible. Plastics like ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid) are broadly adopted on account of their ease of use and good mechanical properties.

The aim of evaluating resin and plastic for 3D printing is to not declare a definitive winner however to focus on their variations and similarities, serving to customers make knowledgeable choices primarily based on their particular wants. This comparability is important because it illuminates the delicate distinctions and sudden similarities between the 2 supplies, which may considerably have an effect on the result of a print job.

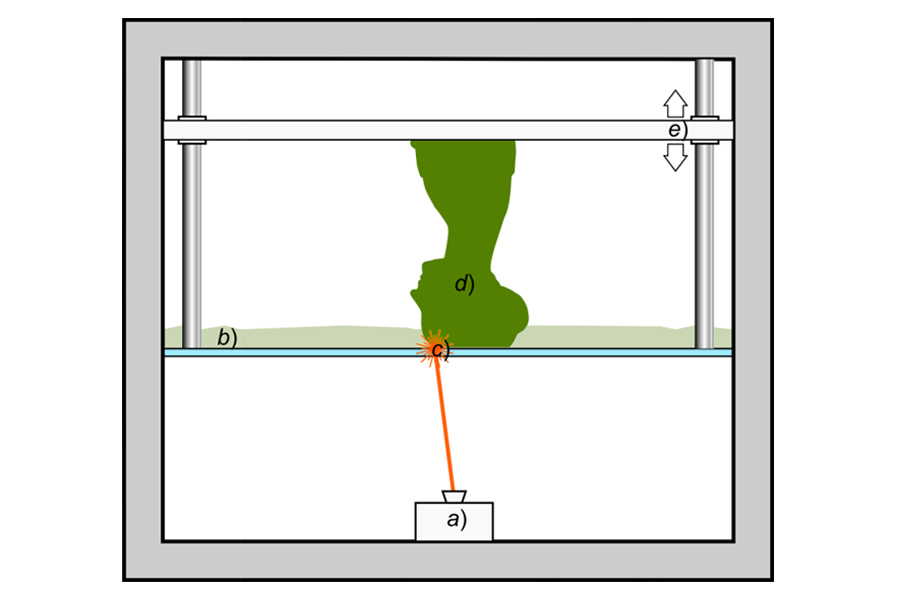

What’s Resin 3D Printing?

Resin 3D printing refers to a gaggle of additive manufacturing applied sciences that create strong objects from liquid photopolymers, layer by layer, by means of a curing process initiated by mild sources equivalent to UV or lasers. This process is distinct from different 3D printing strategies, equivalent to Fused Deposition Modeling (FDM), which extrudes thermoplastic filaments. Resin printers can produce layers as skinny as 0.05 mm, permitting for high-resolution prints.

Advantages and Disadvantages of Resin 3D Printing

| Advantages | Disadvantages |

|---|---|

| Excessive Decision and Precision: Resin 3D printing is able to creating objects with excessive precision and sophisticated particulars, making it a go-to for purposes that require high-resolution parts. | Put up-Processing Necessities: Components from resin 3D printing require some post-processing to take away helps and extra resin. These cleansing steps usually contain utilizing isopropyl alcohol (IPA), however some 3D printing resins may be cleaned with water, thus eliminating the necessity for chemical dealing with. |

| Easy Floor: Components from resin 3D printing usually have a easy floor, making it extremely standard for purposes requiring advantageous options and easy finishes. | Value: The preliminary funding and working prices for resin 3D printing are usually larger in comparison with FDM printing. Moreover, the price of resin can be larger than plastic filaments. |

| Materials Variety: Resin 3D printing makes use of all kinds of supplies, together with normal resins, engineering resins, versatile resins, and water-washable resins. This enables resin 3D printing to satisfy a variety of utility necessities. | Security: The supplies concerned in resin 3D printing may be hazardous to people. Direct contact with resin may cause chemical burns, and the extra one handles resin, the better the potential for issues. Due to this fact, acceptable security measures have to be taken when utilizing resin 3D printing. |

Comparability of SLA Process and Applied sciences, High quality and Element, Materials Properties, and Put up-Processing Necessities

| Side | Stereolithography (SLA) |

|---|---|

| Process and Applied sciences | SLA is a pioneering 3D printing know-how that makes use of an ultraviolet laser to treatment photopolymer resins, creating strong objects from liquid kind. It builds parts layer-by-layer straight from CAD information, which can be utilized for prototypes, casting patterns, instruments, and end-use parts. |

| High quality and Element | Recognized for attaining finer particulars and smoother floor finishes than FDM, SLA can create layers as skinny as 25 microns, leading to an distinctive degree of element and excessive accuracy within the closing product. |

| Materials Properties and Versatility | SLA printing presents a large spectrum of resin properties, catering to varied purposes and end-uses. These resins can mimic a variety of thermoplastics with completely different mechanical, optical, and thermal properties. |

| Put up-Processing Necessities | After printing, parts are cleaned in a solvent resolution to take away residual uncured resin after which cured in a UV oven or beneath UV mild to realize closing hardness and power. |

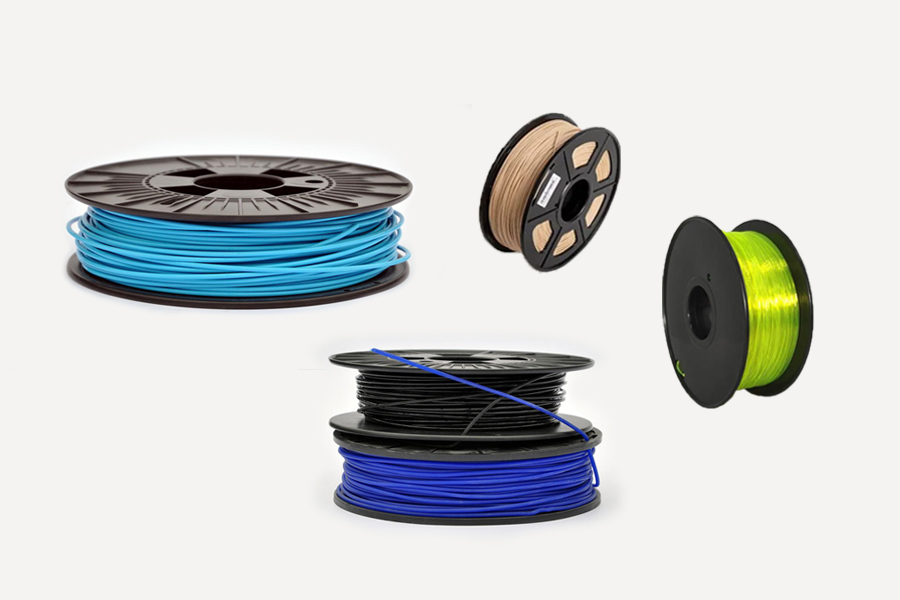

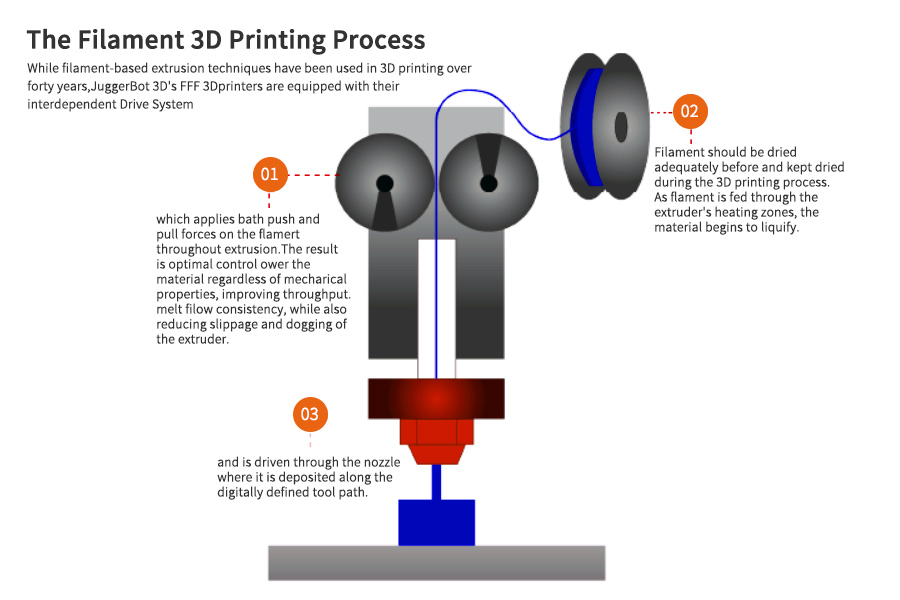

What’s Plastic Filament 3D Printing?

Plastic filament 3D printing, often known as Fused Deposition Modeling (FDM) or Fused Filament Fabrication (FFF), is a process that entails the extrusion of thermoplastic filaments to create strong objects layer by layer. The filament, which is a thermoplastic feedstock, is available in varied diameters and is fed into the printer’s hotend, the place it’s heated previous its glass transition temperature after which extruded onto a construct platform.

Plastic Filament 3D Printing Advantages and Disadvantages

| Advantages | Disadvantages |

|---|---|

| Ease of Use: Plastic filament 3D printing, sometimes called Fused Deposition Modeling (FDM), is usually easy and straightforward to make use of, making it ultimate for rookies and hobbyists. | Decrease Decision: In comparison with resin-based 3D printing, FDM usually has decrease decision and fewer exact detailing. This could restrict its use in purposes that require excessive ranges of element and precision. |

| Affordability: FDM printers and their supplies (plastic filaments) are comparatively cheap. This makes it a well-liked selection for these with a restricted price range or who’re simply getting began with 3D printing. | Floor End: FDM prints usually have a rougher floor end, and visual layer traces are frequent. Put up-processing (like sanding or portray) could also be required to realize a easy, completed look. |

| Materials Versatility: FDM printers can use a variety of thermoplastic filaments, together with PLA, ABS, PETG, and specialty supplies, permitting for a various vary of purposes. | Help Buildings: Designs with overhangs or advanced geometries require assist constructions when utilizing FDM, which have to be manually eliminated after printing. This may be time-consuming and will end in floor blemishes. |

| Security: FDM makes use of thermoplastics that are safer to deal with than resins, making it a safer selection for residence use, faculties, or different environments the place security is a priority. | Velocity: FDM printing tends to be slower, particularly for big or high-resolution prints, in comparison with different 3D printing strategies like SLA or SLS. |

Velocity and Tensile Energy of Filament Printing

The velocity of filament printing is influenced by a number of components, together with the nozzle diameter and the layer peak. Smaller nozzles can produce finer particulars however at a slower velocity, whereas bigger nozzles allow sooner printing. The tensile power of printed parts is affected by printing parameters equivalent to infill density, layer peak, print velocity, and extrusion temperature. Optimizing these parameters can considerably enhance the tensile power of supplies like PLA.

Floor Element and Layer Thickness

The layer thickness, or Z-axis decision, is essential for the floor element of the printed object. Thinner layers enable for larger element, particularly on curved objects or parts with intricate particulars. Nevertheless, printing with thinner layers can enhance the whole print time and will require extra exact calibration and mattress leveling. The stability between velocity and element is a key consideration in filament 3D printing.

Comparative Evaluation of 3D Printing Applied sciences

Decision and Floor End

- SLA (Stereolithography): SLA is famend for its excessive decision and accuracy, producing parts with the clearest particulars and smoothest floor finishes amongst plastic 3D printing applied sciences . The know-how achieves sharp edges and minimal seen layer traces, making it ultimate for purposes requiring advantageous particulars .

- SLS (Selective Laser Sintering): Whereas SLS parts have a barely tough floor end, they exhibit virtually no seen layer traces, providing a stability between smoothness and structural integrity .

- FDM (Fused Deposition Modeling): FDM parts usually present seen layer traces and will have inaccuracies round advanced options, which may have an effect on the general aesthetic and purposeful high quality of the print .

Printing Velocity and Manufacturing Time

- SLA: SLA printers can produce parts with advanced designs and complex options extra effectively than FDM printers . Nevertheless, the manufacturing velocity of 3D printing basically could also be slower in comparison with conventional manufacturing strategies .

- FDM: FDM struggles with advanced designs and complex options, which may decelerate the printing process . Nonetheless, it’s well-suited for fundamental proof-of-concept fashions and fast, low-cost prototyping of easy parts .

- SLS: SLS is good for advanced geometries, together with inside options and skinny partitions, and might produce purposeful parts effectively . Additive manufacturing can scale back lead occasions in situations like product growth and low quantity manufacturing .

Vary of Purposes

- SLA: SLA is used throughout varied industries, together with engineering, product design, manufacturing, dentistry, drugs, jewellery, and schooling, on account of its excessive decision and floor end high quality .

- SLS: SLS is trusted for its means to provide sturdy, purposeful parts and is utilized by engineers and producers throughout completely different industries .

- FDM: FDM is suitable with a variety of normal thermoplastics and is appropriate for prototyping easy parts and fundamental fashions .

Put up-Processing and Ease of Use

- SLA: SLA requires post-processing, together with cleansing and curing, to realize the specified power and stability of parts . This may be time-consuming however is important for high-detail prototypes and purposeful parts.

- SLS: SLS parts have an economical benefit in limited-run or bridge manufacturing and require much less intensive post-processing in comparison with SLA .

- FDM: FDM is usually thought-about user-friendly and requires minimal post-processing, making it accessible for rookies and appropriate for instructional functions.

Business Purposes of 3D Printing

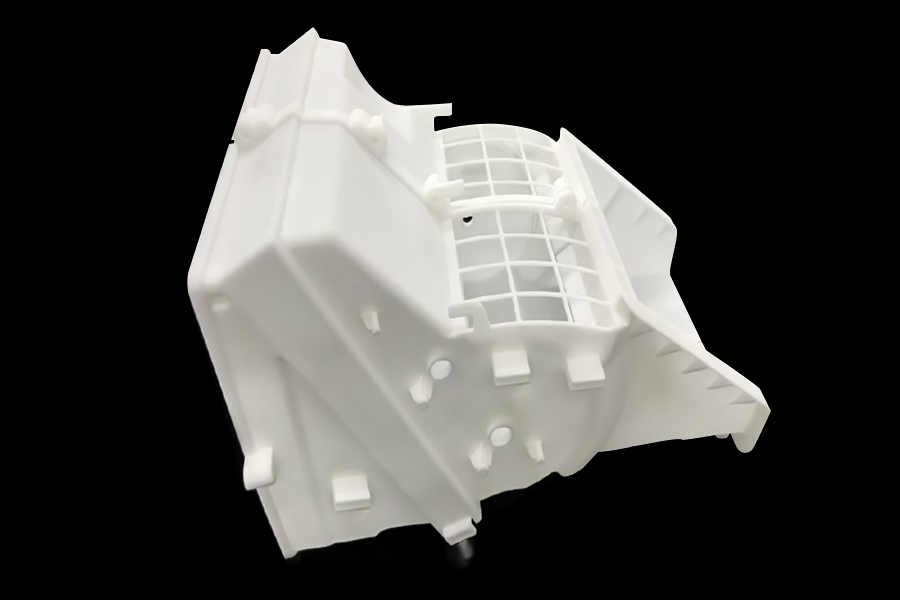

Engineering and Manufacturing

3D printing is revolutionizing engineering and manufacturing by enabling the creation of advanced parts with excessive precision and decreased waste. It permits for fast prototyping, customized tooling, and the manufacturing of end-use parts, usually at a decrease value and with sooner turnaround occasions than conventional manufacturing strategies. The know-how is especially useful for industries equivalent to automotive, aerospace, and building, the place it might probably produce light-weight, well-optimized parts with improved strength-to-mass ratios, contributing to sustainability and innovation. Corporations are more and more adopting 3D printing to provide their very own consumables, equivalent to milling instruments and drill bits, asserting independence from provider schedules. The mixing of 3D printers in manufacturing workflows is saving corporations important quantities of cash, as seen with NGNY, which saves over 40,000€ yearly.

Healthcare and Dentistry

In healthcare, 3D printing is used for patient-specific prosthetics, implants, and even the exploration of bioprinting organs and tissues for transplantation. The dental business, specifically, has seen a big affect from 3D printing, with the know-how enabling the manufacturing of surgical guides, splints, implants, crowns, bridges, and dentures with better accuracy and effectivity. Digital workflows, facilitated by intraoral scanners and 3D printers, scale back errors, labor, and prices, resulting in time and price financial savings for dental practices and laboratories. The adoption of automated 3D printing options, equivalent to Dentsply Sirona’s Primeprint, is making the know-how extra accessible and cost-efficient for dental practices. The accuracy and precision offered by 3D printing know-how result in higher affected person outcomes and the flexibility to satisfy altering affected person expectations.

Schooling and Leisure

3D printing is turning into more and more standard in schooling, offering a hands-on studying expertise for college kids and enabling the creation of advanced fashions for higher understanding of assorted topics. In leisure, the know-how is used to provide intricate props, costumes, and even customized merchandise for followers. The textile business can be experiencing a revolution with 3D printing, resulting in innovation in supplies, manufacturing processes, and design, together with customized clothes gadgets and sophisticated textile patterns.

Jewellery and Audiology

The jewellery business advantages from 3D printing’s means to create advanced and detailed designs that might be tough or not possible to realize with conventional strategies. It permits for fast prototyping and customization of jewellery items. In audiology, 3D printing is used to create custom-made earbuds and listening to help elements, offering an ideal match for the person and bettering consolation and performance.

Comparative Evaluation

| Business | Purposes | Advantages |

|---|---|---|

| Engineering and Manufacturing | Prototyping, tooling, end-use parts | Value financial savings, customization, decreased waste |

| Healthcare and Dentistry | Prosthetics, implants, surgical guides | Affected person-specific options, improved outcomes |

| Schooling and Leisure | Fashions, props, customized gadgets | Enhanced studying, inventive freedom |

| Jewellery and Audiology | Customized jewellery, earbuds, listening to aids | Detailed designs, customized match |

How to decide on the proper 3D printing materials?

When choosing probably the most appropriate 3D printing materials, it is essential to contemplate a number of components:

Printing Accuracy: Totally different supplies supply various ranges of element and precision. As an example, resin-based supplies usually present larger element in comparison with plastic filaments.

Energy and Toughness: The meant use of the printed object could require a fabric that’s sturdy and sturdy. ABS plastic, identified for its power and toughness, is good for parts that want to resist stress.

Temperature Resistance and Chemical Resistance: If the printed object will probably be uncovered to excessive temperatures or particular chemical substances, a fabric that may endure these circumstances is important. Materials like nylon and polycarbonate are identified for his or her good warmth and chemical resistance.

Printing Velocity: Some supplies print sooner than others. If velocity is a precedence, a fabric like PLA, which prints comparatively rapidly, could be your best option.

Value: The price of supplies can considerably range. Whereas some supplies like PLA and ABS are comparatively cheap, others like nylon or specialised resins may be extra expensive. It is essential to stability the associated fee with the opposite components primarily based in your particular wants.

Are you continue to nervous about your 3D printing challenge?

In the event you’re nonetheless involved about your 3D printing challenge, LongSheng might help you. Whether or not it is gear, technical assist, or experience in supplies and design, LongSheng might probably help along with your wants. It is at all times extremely essential to do correct analysis and have interaction with professionals within the discipline to make sure the success of any challenge, together with people who contain 3D printing.

FAQs

Is 3D printing plastic eco pleasant?

Sure, 3D printing with plastic may be eco-friendly. Improvements have led to the event of biodegradable filaments produced from recycled supplies, providing environmentally pleasant alternate options to conventional plastic filaments. Moreover, sustainable 3D printer filaments are being launched to scale back environmental affect, aligning with the rules of the Round Financial system. Nevertheless, it is essential to contemplate the particular supplies and practices employed, as 3D printing usually requires a big quantity of power and infrequently makes use of non-biodegradable supplies.

Is 3D printing resin dangerous for the surroundings?

3D printing resin can have detrimental results on each human well being and the surroundings. The liquid resin utilized in 3D printing is poisonous and might trigger allergic reactions if it comes into contact with the pores and skin or eyes. Moreover, uncured liquid resin comprises irritants and pollution which can be dangerous to people and the surroundings. Correct precautions and security measures are crucial when working with 3D printing resin to attenuate these dangers. Moreover, the disposal of leftover resin should be dealt with rigorously to stop hurt to the surroundings, equivalent to by avoiding pouring it down the drain. Due to this fact, it is essential to be conscious of the potential environmental affect when utilizing 3D printing resin.

Pingback: Resin Vs. Plastic: Understanding The Core Differences For Better Material Selection