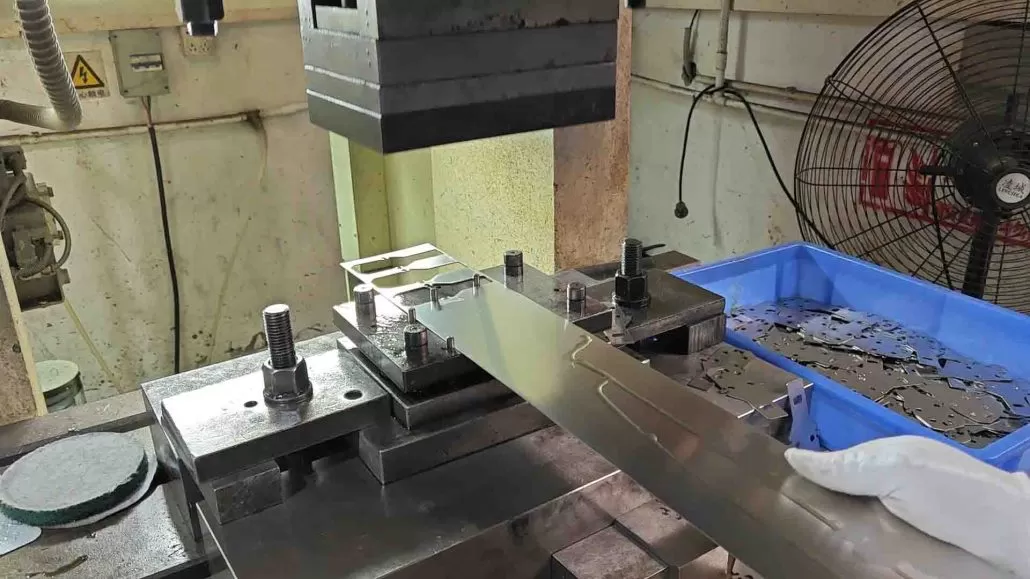

Metal stamping is a manufacturing process that involves shaping metal sheets into different forms and sizes using a press machine. This process requires a lot of force and pressure, which can cause friction and heat buildup between the metal and the stamping die. To prevent damage to the metal and the die, lubricant is used to reduce friction and heat and to improve the overall quality of the stamped parts.

There are several reasons why lubricant is used in metal stamping:

- Reduce Friction: Friction between the metal and the stamping die can cause wear and tear on both surfaces, leading to damage and reduced tool life. By applying lubricant, the friction is reduced, allowing the metal to slide more smoothly over the die and reducing the risk of damage.

- Prevent Heat Buildup: The pressure and force exerted during metal stamping can generate a lot of heat, which can cause the metal to become deformed or damaged. Lubricant helps to dissipate this heat, preventing the metal from overheating and ensuring that it retains its shape and quality.

- Improve Surface Finish: Lubricant can also help to improve the surface finish of the stamped parts. By reducing friction and heat, lubricant reduces the risk of scratches and other surface defects, resulting in a smoother and more polished finish.

- Increase Production Efficiency: By reducing friction and heat, lubricant also helps to improve the overall efficiency of the metal stamping process. With less wear and tear on the tools, production can be increased, and downtime can be reduced.

In conclusion, lubricant is a critical component of the metal stamping process, helping to reduce friction, prevent heat buildup, improve surface finish, and increase production efficiency. With the right lubricant, manufacturers can ensure that their stamped parts are of the highest quality, while also extending the life of their stamping dies and reducing maintenance costs

Lubricant Used in Metal Stamping

Metal stamping is a process that involves using a punch press to force a tool and die set against a metal sheet. This process creates various shapes and forms in the metal. However, this process can create a lot of heat and friction, which can damage the metal sheet or the tool and die set. A lubricant is used to protect the metal sheet and the tool and die set from damage.

The lubricant used in metal stamping is typically a mineral oil-based lubricant. This lubricant is specially formulated to withstand the high temperatures and pressures involved in metal stamping. It also helps to minimize friction and wear on the tool and die set, which can extend their lifespan.

There are different types of lubricants used in metal stamping, including dry film lubricants, oil-based lubricants, and synthetic lubricants. The type of lubricant used depends on the material being stamped, the type of tool and die set being used, and the specific requirements of the stamping process.

In addition to protecting the metal sheet and the tool and die set, lubricants also help to improve the quality of the stamped parts. Lubricants can reduce burrs, improve surface finish, and make it easier to remove the stamped parts from the die.

Overall, lubricants play an essential role in the metal stamping process. They protect the metal sheet and the tool and die set from damage, improve the quality of the stamped parts, and help to extend the lifespan of the tool and die set.

.