Medical CNC machining has revolutionized the way medical devices and implants are manufactured. With the use of advanced technology, CNC machining has allowed for greater precision and accuracy in the production of vital medical components. When it comes to medical equipment, precision is critical – even the slightest discrepancies can have serious consequences for patients. Hence, precision is a critical factor in medical CNC machining.

The importance of precision in medical CNC machining lies in its ability to produce exact dimensions, resulting in a perfectly precise device or implant. A CNC machine is capable of producing components within a few micrometers, which is impossible to achieve with manual or traditional machining methods.

The precision in medical CNC machining has a direct impact on product quality, reliability, and post-processing. Accuracy is significant in medical CNC machining to ensure that every device or implant aligns precisely to the required measurements.

The medical device industry depends heavily on CNC machining as it enables the design and manufacture of critical components such as surgical instruments, prosthetic implants, and medical equipment. With the use of CAD/CAM software and CNC machines, engineers can easily create complex shapes and designs, which would otherwise be unattainable. CNC machining provides the necessary precision to manufacture intricate components and devices.

Precision Ensures Quality and Safety

CNC machining in the medical industry demands an extremely high level of precision. Inaccurate or poorly manufactured medical parts may result in severe consequences, such as device failure or even harm to patients. Precision is crucial in all stages of production, from the design of the part to the execution of the manufacturing process. A high level of accuracy in the final product guarantees that the device will function as intended, free from abnormalities or defects that could cause potential hazards.

Grinding, Turning, CNC, and Quality Control Technologies

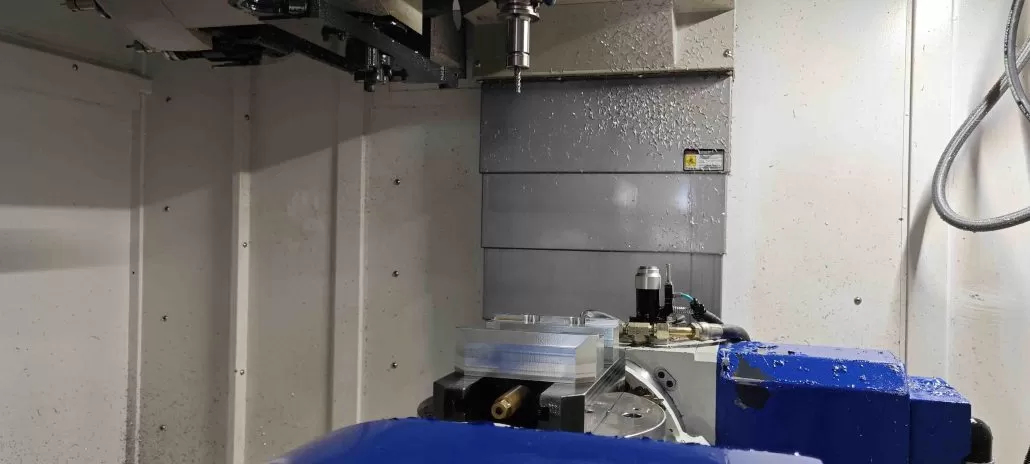

To ensure precision in CNC machining, cutting-edge technology and equipment must be employed at all stages. Grinding, turning, CNC milling, and quality control technologies are all essential tools that contribute to achieving the required levels of accuracy and consistency. Grinding is a critical process for achieving precise surface finishes through the use of abrasive grains and wheels. Turning technology, on the other hand, relies on the precise removal of material through computer-controlled cutting tools. Finally, CNC milling uses milling machines that remove material from a larger workpiece to create intricate, precise cuts.

Quality control technologies, such as inspection and testing, are essential to ensure that the finished product conforms to the required specifications. To test the parts, they must be measured using dimension gauging and surface testing equipment. In addition, the geometrical and dimensional tolerances must be verified through CMM (coordinate measuring machine) inspection, which ensures that every aspect of the device meets the exacting standards required for medical applications.

Why is Precision Vital in Medical CNC Machining?

Medical devices are intricate machines designed to be precise. Any deviation in the size of medical components can affect their performance and influence patient safety. Medical CNC machine parts are cut to the most exact tolerances, providing a level of accuracy that cannot be achieved by other manufacturing methods.

CNC machining is the most precise method of cutting medical-grade materials. CNC machines produce components with an accuracy of up to 0.0001 inches (.002mm). When CNC medical parts are used to create medical devices, they are durable, safe, and reliable, making them one of the most critical components in patient safety.

Another reason why precision is important in medical CNC machining is because of the regulations and quality control associated with the medical industry. Medical devices are held to some of the highest standards when it comes to safety and effectiveness. Every component must be rigorously tested and approved before it can be used in a medical application. Therefore, CNC machining companies must adhere to strict regulations and standards to ensure that their parts are up to code.

Moreover, precision is crucial for achieving consistent results in medical CNC machining. In the medical industry, many devices require identical or nearly identical components, such as knee implants, pacemakers, and hearing aids. In such cases, CNC machining provides a high degree of repeatability and consistency. This not only improves the quality of the parts, but it also reduces costs and minimizes waste.

The Importance of Quality Standards in Medical CNC Machining

Manufacturers of medical devices and equipment must comply with strict regulations and quality standards when producing their products. These standards are designed to ensure that medical devices are of the highest quality and meet specific safety and performance requirements.

Adhering to quality standards is vital in the medical industry. The slightest variation in the quality of a medical device can have catastrophic results. Every part produced using CNC medical machining should go through rigorous inspections and tests to ensure that it meets all the required specifications. In addition, manufacturers must ensure that all aspects of their manufacturing process comply with industry standards.

How Precision CNC Medical Components Can Help Fight Medical Conditions

CNC medical components are used in several different medical conditions ranging from cancer treatment machines to life-support equipment. Many medical conditions rely heavily on life-support equipment, making the parts used in the machinery essential.

Medical device manufacturers must produce precision-made components to ensure that they are safe, reliable, and efficient. This is where CNC machining comes in. CNC medical parts require less finishing work, reducing manufacturing time, and increasing the production speed. This makes the manufacturing process more efficient and cost-effective.

Cancer treatment machines are also an important area of medical CNC machining. These machines rely on very precise lasers to create the targeted cancerous tissue ablation. This precision is essential for the patient’s safety, as it ensures that healthy tissue is not affected during the treatment.

How We Ensure Precision in CNC Medical Components

At CNC parts online and Turning parts online, we understand the importance of medical CNC machining and the impact it can have on the patients. Our technicians are highly skilled, trained, and experienced in medical CNC machining. Our manufacturing process is innovative, efficient, and cost-effective, allowing us to produce precise CNC medical components with speed and accuracy.

We use the latest CAD/CAM software coupled with state-of-the-art CNC machines to produce medical components with the highest levels of precision possible. Our quality assurance program ensures that all components meet strict criteria, thereby reducing any risks associated with manufacturing.

The Impact of Precision on the Healthcare Industry

The importance of precision in medical CNC machining goes far beyond just the manufacturing process. The healthcare industry as a whole is affected by the quality of the parts produced. If medical components are unreliable or inaccurate, it can lead to increased healthcare costs, wasted resources, and potentially harm to patients.

On the other hand, precision in medical CNC machining can have significant positive impacts. It can lead to more efficient surgical procedures, reduce patient recovery times, and improve the overall quality of care. Precision also enables the production of smaller and more intricate parts, allowing for greater innovation in medical device design and functionality. With continued advancements in CNC machining technology, the medical industry can continue to improve and refine medical devices to better meet the needs of patients.

Expert CNC Machining Professionals and Processes

Achieving precision in CNC machining for the medical industry requires skilled professionals with expertise in the processes and machinery used in the production of medical parts. From the initial design to final production, expert machinists work tirelessly to ensure that every aspect of the process is consistent and accurate. These professionals use cutting-edge software to design and manufacture parts, ensuring that all design specifications are maintained throughout the entire process.

In addition to human expertise, medical CNC machining also requires specific processes to achieve the highest levels of accuracy. Processes such as deburring, which is a finishing technique used to remove sharp edges and burrs that can cause unintended injuries to patients. They also include finishing and, polishing which are intended to ensure that the final products have a seamless and flawless surface.

Conclusion

Precision is the backbone of medical CNC machining. The medical industry depends entirely on precision, accuracy, and consistency to produce high-quality medical devices and equipment. Precision in CNC machining means zero defects, which translates into enhanced safety for medical professionals and patients.

The importance of meeting quality standards can’t be overstated in medical CNC machining. Any defect in the production process can create dangerous situations that can be life-threatening. As such, CNC medical machining companies must continually invest in their equipment and staff to ensure they can produce high-quality medical devices that meet all industry standards.

As a CNC parts online and turning parts online supplier, our company follows strict quality control standards to ensure that every one of our products meets all required specifications. We take pride in our professional approach to CNC medical machining, and we will continue to strive for precision, consistency, and accuracy in every task we undertake.